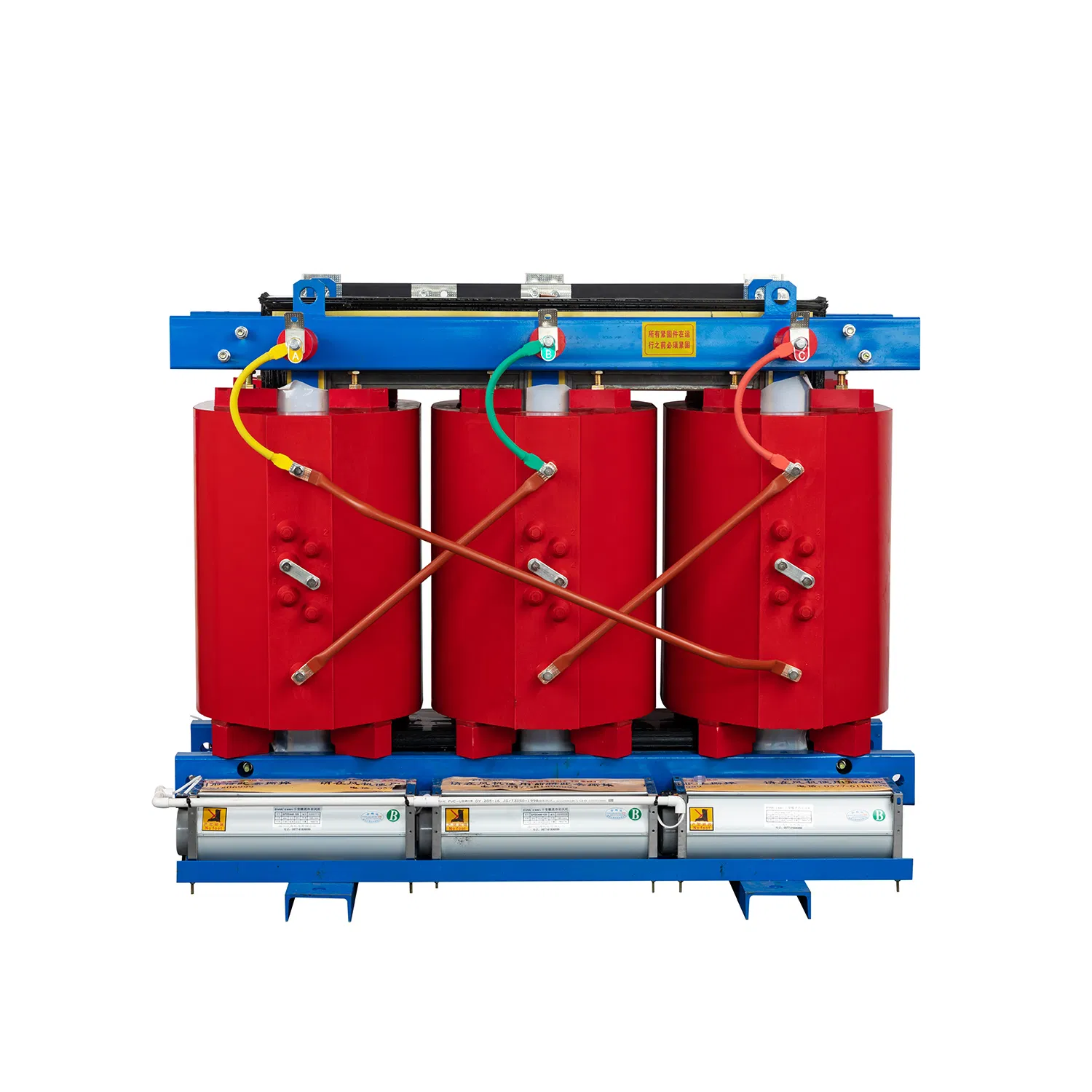

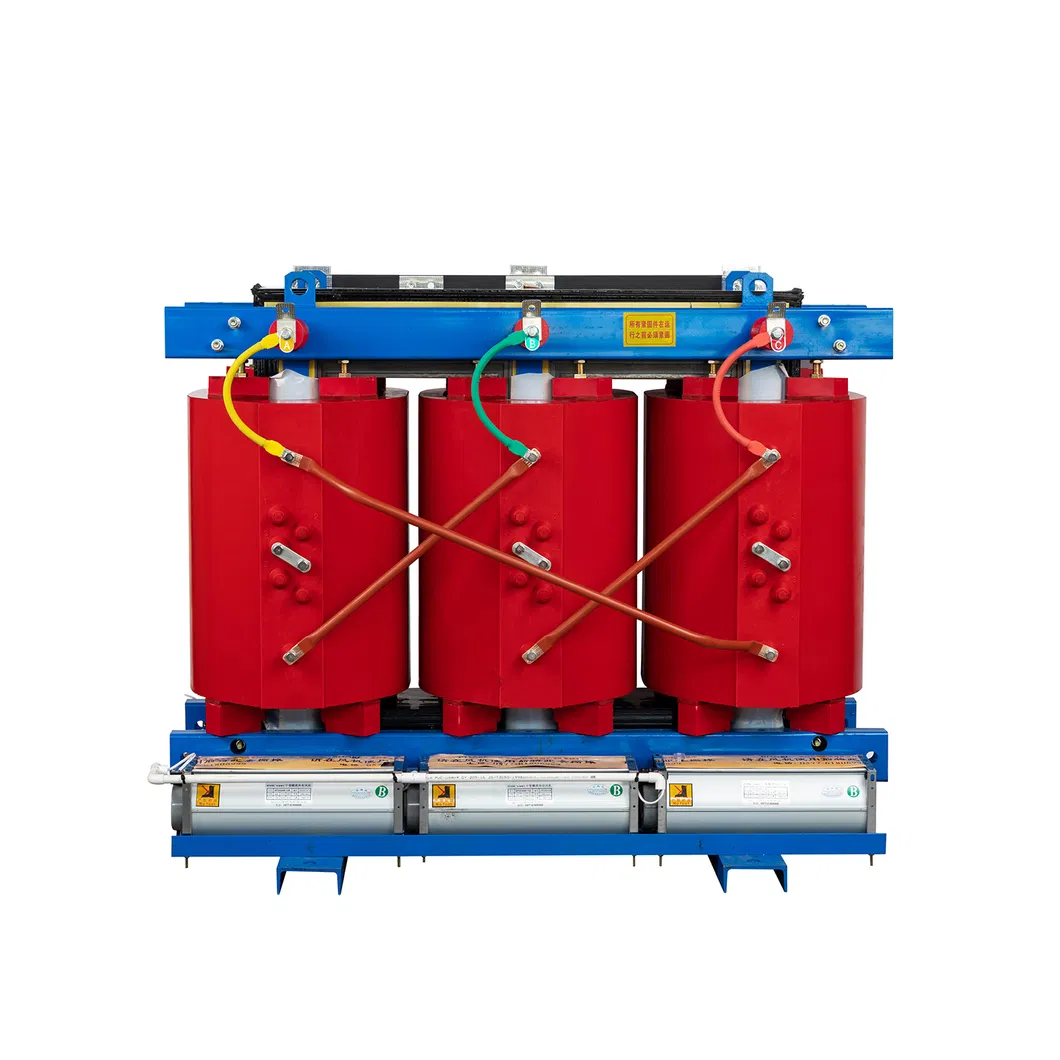

Epoxy Resin Casting 11kVA Dry-Type Distribution Transformer

Overview & featuresAs the coils of resin-insulated dry-type transformer are encapsulated by the epoxy resin, they are nonflammable, fireproof, explosion-proof, maintenance-free, no pollution, small volume, and can be installed in the load center directly. Meanwhile, the scientific and reasonable......

Send Inquiry

Product Description

Overview & features

As the coils of resin-insulated dry-type transformer are encapsulated by the epoxy resin, they are nonflammable, fireproof, explosion-proof, maintenance-free, no pollution, small volume, and can be installed in the load center directly. Meanwhile, the scientific and reasonable design and casting technology enable the products to have lower discharge capacity, low noise and strong heat dissipation, they are able to run for a long time under 140% rated load under forced air cooling condition. Besides, the products are equipped with intelligent temperature controllers, have functions of trouble alarm, over-temperature alarm, over-temperature tripping and black box, can be connected with the computer through RS485 serial interface to realize centralized monitoring and control.

Due to the above features, our epoxy resin casting dry type transformers can be widely applied to power transmission and transformation systems in hotels, restaurants, airports, high-rise buildings, commercial centers, residential districts, and the severe environments such as underground railways, smelting, electric power plants, steamships, offshore oil-drilling platforms, etc.

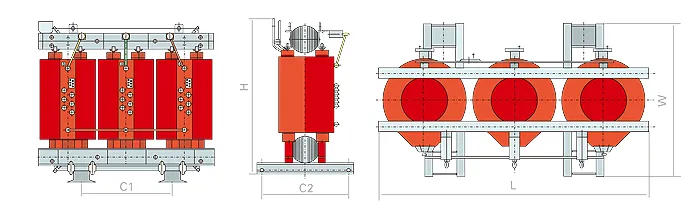

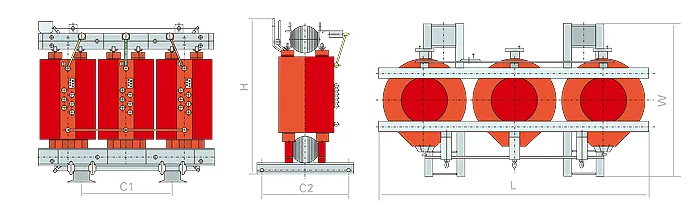

Dimensions & Schematic

| Rated capacity | Installation dimension | |||||

| (kVA) | L | W | H | C1 | C2 | |

| 30 | 580 | 405 | 600 | 300 | 300 | |

| 50 | 620 | 475 | 730 | 300 | 350 | |

| 80 | 900 | 500 | 820 | 450 | 450 | |

| 125 | 970 | 500 | 890 | 450 | 450 | |

| 160 | 1060 | 650 | 930 | 550 | 550 | |

| 200 | 1100 | 650 | 985 | 550 | 550 | |

| 250 | 1140 | 760 | 1070 | 550 | 550 | |

| 315 | 1170 | 760 | 1130 | 660 | 660 | |

| 400 | 1260 | 760 | 1155 | 660 | 660 | |

| 500 | 1300 | 760 | 1190 | 660 | 660 | |

| 630 | 1370 | 760 | 1220 | 660 | 660 | |

| 800 | 1440 | 760 | 1225 | 660 | 660 | |

| 1000 | 1480 | 920 | 1330 | 820 | 820 | |

| 1250 | 1580 | 920 | 1480 | 820 | 820 | |

| 1600 | 1660 | 920 | 1550 | 820 | 820 | |

| 2000 | 1720 | 920 | 1710 | 820 | 820 | |

| 2500 | 1820 | 920 | 1780 | 1070 | 1070 | |

Technical parameters

| Rated capacity | Voltage combination | Connection group | Loss (KW) | No-load current | Short-circuit impedance | Weight (kg) | ||||

| (kVA) | HV(kV) | High-voltage tapping range | LV(kV) | symbol | No-load | On-load(120°) | (%) | (%) | Body weight | Weight with shell |

| 30 | 6 6.3 6.6 10 10.5 11 |

±5% ±2×2.5% | 0.4 |

Yyn0 Dyn11 | 0.22 | 0.75 | 3.2 | 4.0 | 220 | 250 |

| 50 | 0.31 | 1.05 | 2.8 | 360 | 410 | |||||

| 80 | 0.42 | 1.46 | 2.6 | 450 | 190 | |||||

| 100 | 0.45 | 1.67 | 2.4 | 540 | 580 | |||||

| 125 | 0.53 | 1.95 | 2.2 | 630 | 670 | |||||

| 160 | 0.61 | 2.25 | 2.2 | 745 | 795 | |||||

| 200 | 0.70 | 2.67 | 2 | 850 | 910 | |||||

| 250 | 0.81 | 2.92 | 2.2 | 1010 | 1065 | |||||

| 315 | 0.99 | 3.67 | 1.8 | 1235 | 1295 | |||||

| 400 | 1.10 | 4.22 | 1.8 | 1370 | 1430 | |||||

| 500 | 1.35 | 5.17 | 1.8 | 1565 | 1625 | |||||

| 630 | 1.51 | 6.22 | 1.6 | 1855 | 1930 | |||||

| 630 | 1.46 | 6.31 | 1.6 | 6.0 | 1800 | 1875 | ||||

| 800 | 1.71 | 7.36 | 1.6 | 2140 | 2215 | |||||

| 1000 | 1.99 | 8.60 | 1.4 | 2535 | 2620 | |||||

| 1250 | 2.35 | 10.26 | 1.4 | 3100 | 3190 | |||||

| 1600 | 2.75 | 12.42 | 1.4 | 3705 | 3830 | |||||

| 2000 | 3.74 | 15.30 | 1.2 | 4230 | 4380 | |||||

| 2500 | 4.50 | 18.18 | 1.2 | 5230 | 5280 | |||||

Overview & features

As the coils of resin-insulated dry-type transformer are encapsulated by the epoxy resin, they are nonflammable, fireproof, explosion-proof, maintenance-free, no pollution, small volume, and can be installed in the load center directly. Meanwhile, the scientific and reasonable design and casting technology enable the products to have lower discharge capacity, low noise and strong heat dissipation, they are able to run for a long time under 140% rated load under forced air cooling condition. Besides, the products are equipped with intelligent temperature controllers, have functions of trouble alarm, over-temperature alarm, over-temperature tripping and black box, can be connected with the computer through RS485 serial interface to realize centralized monitoring and control.

Due to the above features, our epoxy resin casting dry type transformers can be widely applied to power transmission and transformation systems in hotels, restaurants, airports, high-rise buildings, commercial centers, residential districts, and the severe environments such as underground railways, smelting, electric power plants, steamships, offshore oil-drilling platforms, etc.

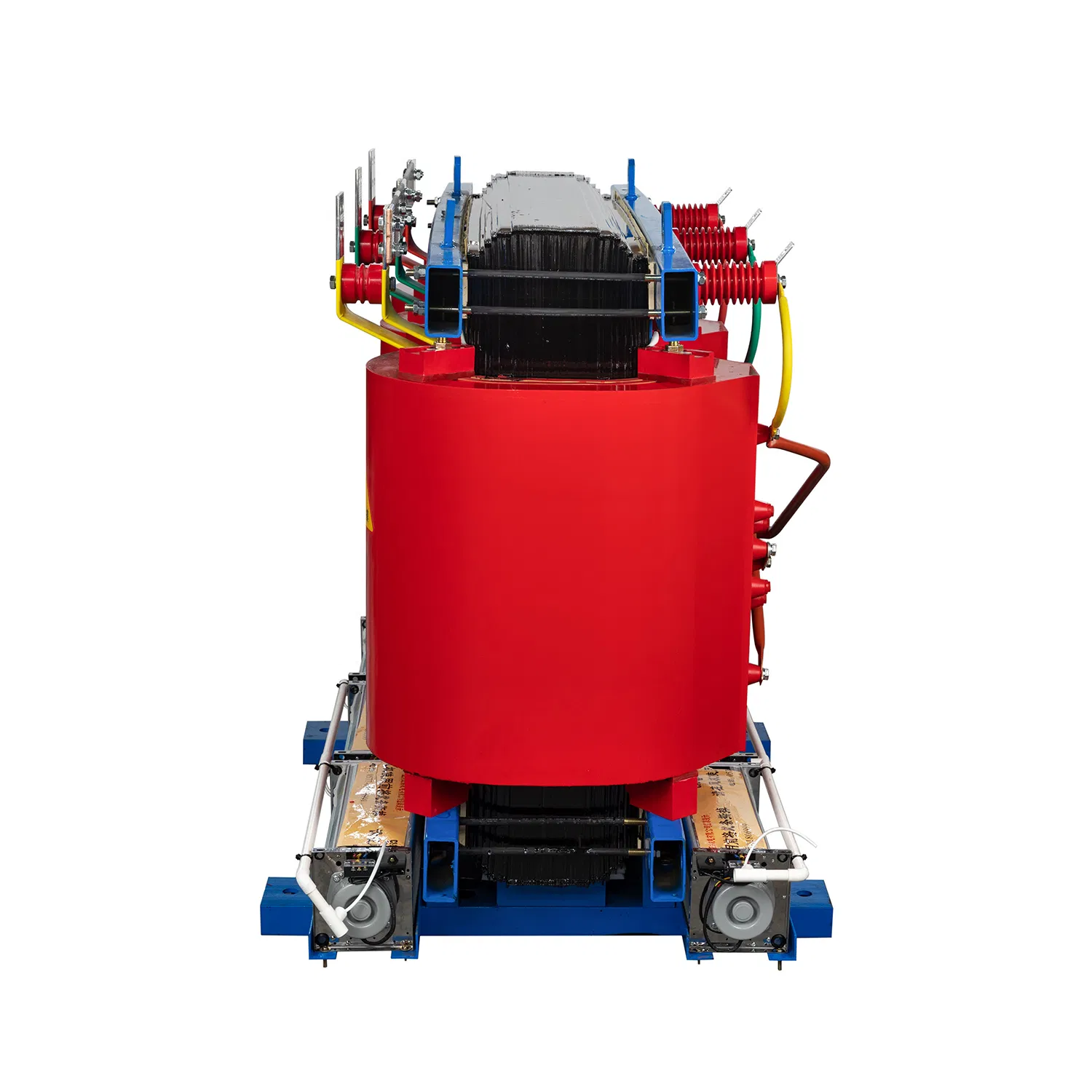

Iron core

The iron core is made of imported cold-rolled silicon steel sheets with inclined joint structure, core limbs are bound by unidirectional weftless tape of class F.

Surface of iron core is encapsulated with epoxy resin, which reduces the no-load noise, no-load current and core noise.

Clamps and fasteners have gone through special surface treatment that further improves the product appearance quality.

High-voltage winding

High-voltage winding applies vacuum casting of stuffing epoxy resin which sharply reduces partial discharge capacity and enhances the electric strength of coils. The inside and outside of the winding is buildup with glass fiber grid overlay which strengthens the mechanical robustness of coils and product's short-circuit withstand capability, the coil will not split forever.

Low-voltage winding

Low-voltage winding applies foil structure which solves the problem of axial helix angle when winds and make the ampere-turn of winding distribute evenly. Meanwhile, the coils adopt axial cooling duct to improve the heat dissipation. Between the layers of winding, it applies DMD epoxy resin preliminary immersed cloth and makes it whole solidification forming.

Manufacturing process

The coils are wound on high precision winding machine. We adopt foil type winding structure for low-voltage windings. Transformers of larger capacity are equipped with ventilating duct. It is vacuum drying, casting and solidification followed the winding, all processes are operated accord with the technological requirements under strict monitoring and may be regulated as appropriate. The precise manufacturing of casting ensures no bubble or cavity in coil, and gets high quality operation of transformer finally.

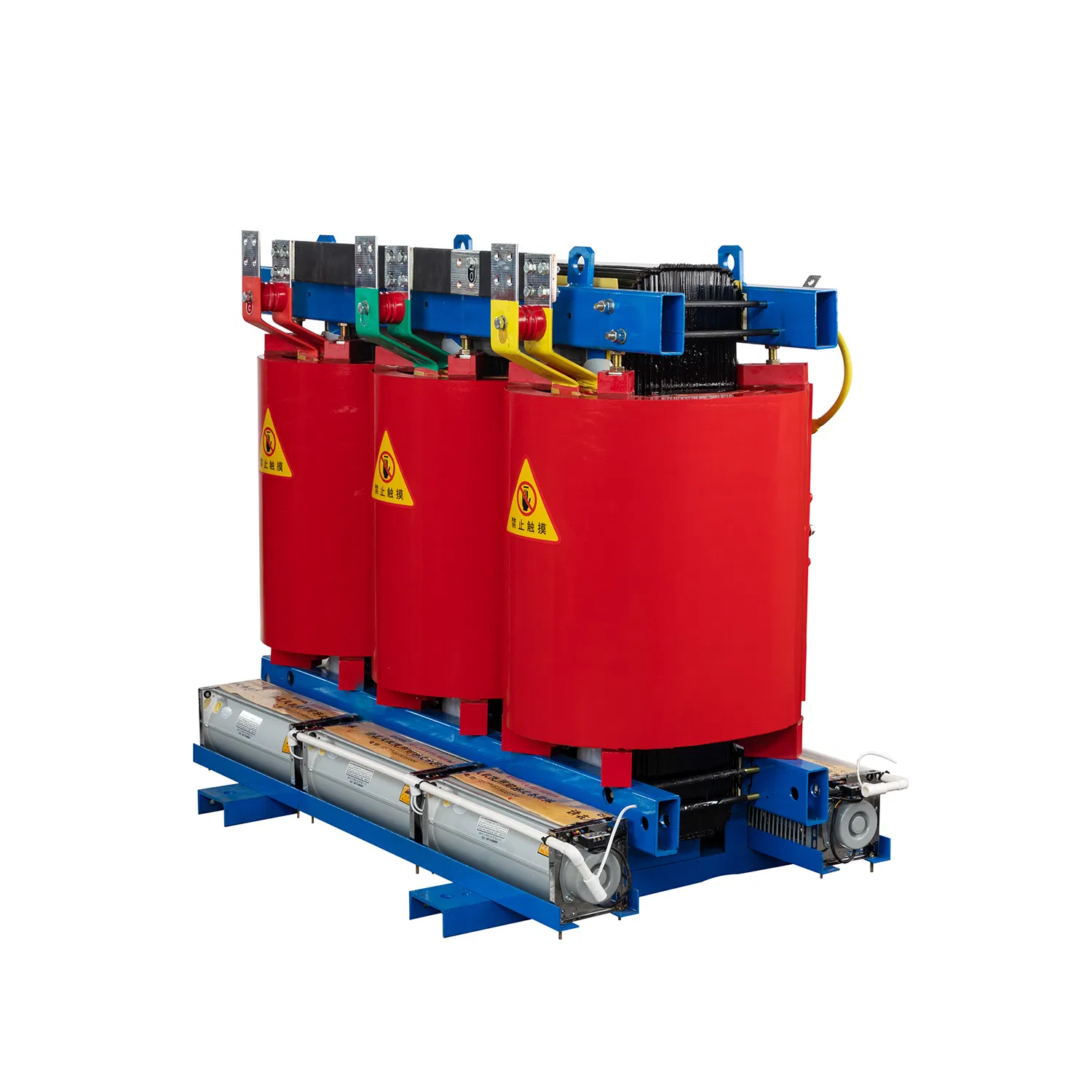

Temperature control and air cooling systems

It adopts crossflow top-blow fan which is featured with low noise, high wind pressure and good looking, etc., it improves the safety and reliability of the operation of transformer.

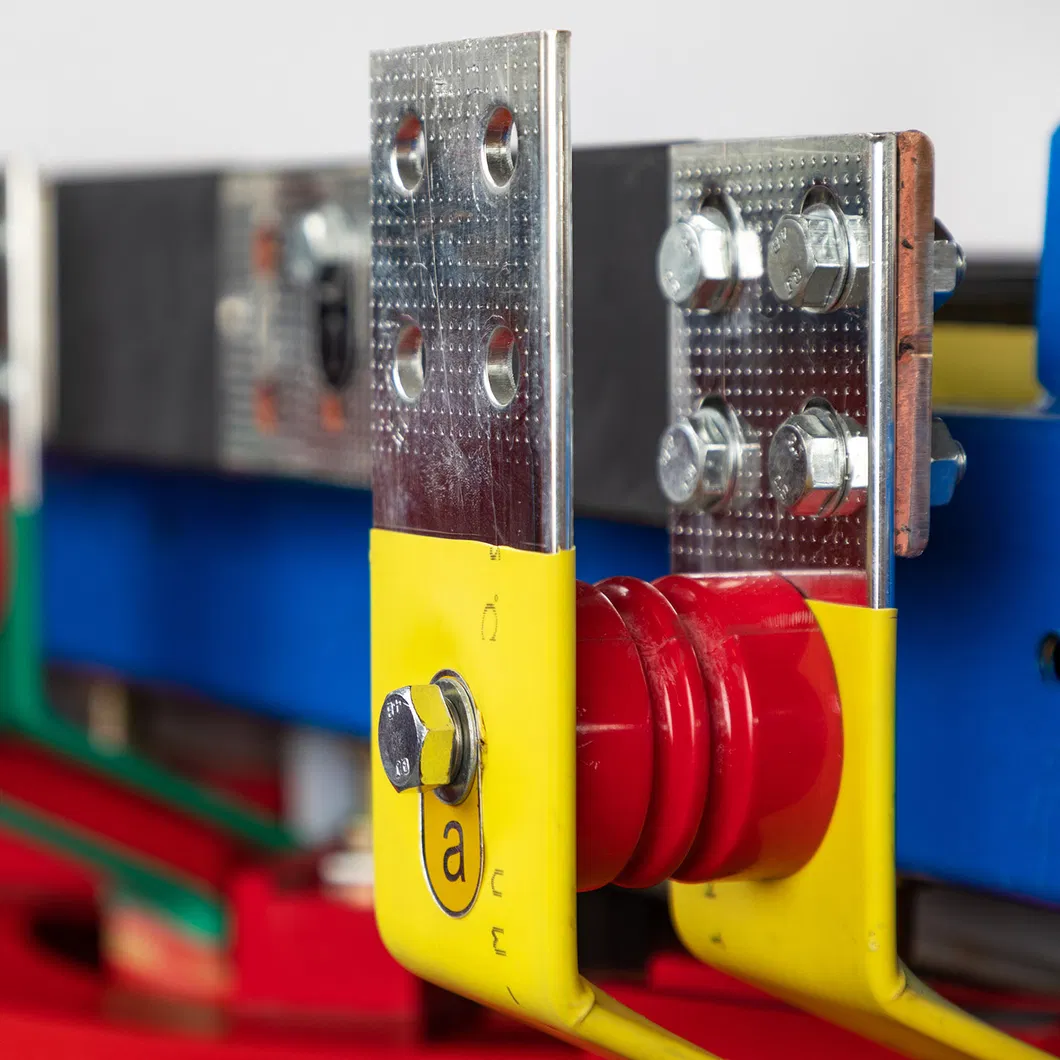

Protective shell and outgoing bus

The shell makes further protection for the transformer. For user's option, the grade of protection has IP20, IP23, etc. Shell materials include cold-rolled steel sheets, stainless steel sheets and so on for option. The low-voltage outgoing adopts standard outgoing bus, side outgoing and top outgoing are available, or design special outgoing modes for users.

Service conditions

A. Installation height: altitude shall not exceed 1000m;

B.Waveform of source voltage is approximate to sine wave;

C.Symmetry of multi-phase source voltage:

connected voltage of multi-phase transformer should be symmetrical approximately.

D. Ambient temperature:

Max temperature +40ºC

Max daily mean air temperature: +30ºC

Max annual mean air temperature: +20ºC

Min air temperature: -30ºC (applicable for indoor transformers)

Dimensions & Schematic

| Rated capacity | Installation dimension | |||||

| (kVA) | L | W | H | C1 | C2 | |

| 30 | 580 | 405 | 600 | 300 | 300 | |

| 50 | 620 | 475 | 730 | 300 | 350 | |

| 80 | 900 | 500 | 820 | 450 | 450 | |

| 125 | 970 | 500 | 890 | 450 | 450 | |

| 160 | 1060 | 650 | 930 | 550 | 550 | |

| 200 | 1100 | 650 | 985 | 550 | 550 | |

| 250 | 1140 | 760 | 1070 | 550 | 550 | |

| 315 | 1170 | 760 | 1130 | 660 | 660 | |

| 400 | 1260 | 760 | 1155 | 660 | 660 | |

| 500 | 1300 | 760 | 1190 | 660 | 660 | |

| 630 | 1370 | 760 | 1220 | 660 | 660 | |

| 800 | 1440 | 760 | 1225 | 660 | 660 | |

| 1000 | 1480 | 920 | 1330 | 820 | 820 | |

| 1250 | 1580 | 920 | 1480 | 820 | 820 | |

| 1600 | 1660 | 920 | 1550 | 820 | 820 | |

| 2000 | 1720 | 920 | 1710 | 820 | 820 | |

| 2500 | 1820 | 920 | 1780 | 1070 | 1070 | |

Technical parameters

| Rated capacity | Voltage combination | Connection group | Loss (KW) | No-load current | Short-circuit impedance | Weight (kg) | ||||

| (kVA) | HV(kV) | High-voltage tapping range | LV(kV) | symbol | No-load | On-load(120°) | (%) | (%) | Body weight | Weight with shell |

| 30 | 6 6.3 6.6 10 10.5 11 |

±5% ±2×2.5% | 0.4 |

Yyn0 Dyn11 | 0.22 | 0.75 | 3.2 | 4.0 | 220 | 250 |

| 50 | 0.31 | 1.05 | 2.8 | 360 | 410 | |||||

| 80 | 0.42 | 1.46 | 2.6 | 450 | 190 | |||||

| 100 | 0.45 | 1.67 | 2.4 | 540 | 580 | |||||

| 125 | 0.53 | 1.95 | 2.2 | 630 | 670 | |||||

| 160 | 0.61 | 2.25 | 2.2 | 745 | 795 | |||||

| 200 | 0.70 | 2.67 | 2 | 850 | 910 | |||||

| 250 | 0.81 | 2.92 | 2.2 | 1010 | 1065 | |||||

| 315 | 0.99 | 3.67 | 1.8 | 1235 | 1295 | |||||

| 400 | 1.10 | 4.22 | 1.8 | 1370 | 1430 | |||||

| 500 | 1.35 | 5.17 | 1.8 | 1565 | 1625 | |||||

| 630 | 1.51 | 6.22 | 1.6 | 1855 | 1930 | |||||

| 630 | 1.46 | 6.31 | 1.6 | 6.0 | 1800 | 1875 | ||||

| 800 | 1.71 | 7.36 | 1.6 | 2140 | 2215 | |||||

| 1000 | 1.99 | 8.60 | 1.4 | 2535 | 2620 | |||||

| 1250 | 2.35 | 10.26 | 1.4 | 3100 | 3190 | |||||

| 1600 | 2.75 | 12.42 | 1.4 | 3705 | 3830 | |||||

| 2000 | 3.74 | 15.30 | 1.2 | 4230 | 4380 | |||||

| 2500 | 4.50 | 18.18 | 1.2 | 5230 | 5280 | |||||

ABOUT OUR COMPANY

a).HONLE Group co.,Ltd is specified in producing power supply such as Single phase and three phase voltage stabilizers, voltage regulator, distribution transformers, low-voltage switch gear assembly,complete plant equipment etc.

b)Passed the ISO9001 quality management system certification

c).HONLE insist on the quality of survival ,innovation and development all the time , try our best to be winner to give you the competitive product .

Our service :

a)Quick response to your inquiry

b)best quality with reasonable price

c)long warranty ensure you buy with no hesitation

FAQ:

Q1.WHY CHOOSE US

A--Best quality with reasonable price .You will realize the answer when you compare ours product with others

Q 2. what's the payment term?

A --We usually accept TT, 30% deposit and 70% balance against copy of BL

Q 3. how's the delivery time ?

A --Usually it will take about 25 days for production.

Q 3. tell me the standard of package?

A --For the small capacity, it use carton, but for big capacity, we should use strong wooden case for protection.

Q4. what kind of certificate you have ?

A. Our company already achieve ISO, CCC, and for products, we have CE

Q5.How long is your product warranty

A.2 years warranty after manufacturing date

More question?

PLEASE FEEL FREE TO CONTACT US YOU CAN GET OUR IMMEDIATE REPLY

Related Category

Connector & Terminals

Sensor

Switch

Transformer

Circuit Board

Breaker & Protector

Socket & Outlet

Terminals

Remote Control

Inverter

Electronic Tube & Transistor

Capacitor

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.