Why Turnkey PCB Assembly Essential for Modern Electronics

2025-08-21

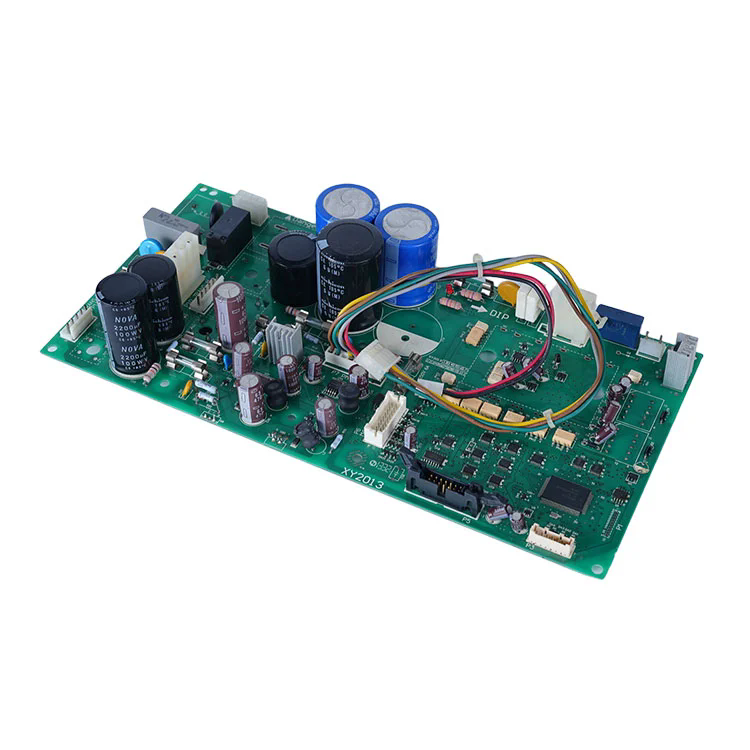

Turnkey PCB Assembly refers to a comprehensive manufacturing service where a single provider handles the entire printed circuit board (PCB) assembly process, from sourcing components and fabricating boards to final assembly and quality testing. This approach is gaining popularity among OEMs, startups, and electronics manufacturers because it reduces lead times, lowers costs, and minimizes project management hassles.

Unlike traditional PCB assembly, where the client procures components and sends them to an assembler, a turnkey solution integrates all stages into a single seamless workflow. This is particularly beneficial for high-tech industries such as IoT devices, automotive electronics, medical equipment, industrial automation, and consumer electronics.

Key Benefits of Turnkey PCB Assembly

-

Faster Time-to-Market – Centralized component sourcing and manufacturing eliminate unnecessary delays.

-

Lower Operational Costs – Bulk purchasing and optimized production save money.

-

Improved Quality Control – Consistent standards from start to finish reduce errors.

-

Scalability – Suitable for both prototyping and mass production without changing suppliers.

-

Streamlined Communication – One partner manages everything, reducing miscommunication.

The growing demand for miniaturized devices and high-density PCBs has made turnkey assembly a preferred solution worldwide.

The Complete Turnkey PCB Assembly Process

To fully understand the value of turnkey PCB assembly, let’s break down the step-by-step process:

PCB Design Verification

Before production begins, the provider reviews Gerber files, BOMs (Bill of Materials), and schematic layouts to ensure compatibility and manufacturability.

Component Procurement

Turnkey providers leverage global supply chain networks to source components quickly and at competitive prices. Trusted distributors like Digi-Key, Mouser, and Arrow are often used to avoid counterfeit parts.

PCB Fabrication

The PCB itself is manufactured using high-precision etching, drilling, and plating techniques. For high-frequency and HDI (High-Density Interconnect) boards, advanced lamination technologies are applied.

Surface Mount Technology (SMT) Assembly

-

Automated Pick-and-Place Machines position components accurately.

-

Reflow Soldering ensures reliable connections.

-

Automated Optical Inspection (AOI) detects defects early.

Through-Hole Assembly

For components requiring mechanical stability, wave soldering or selective soldering techniques are used.

Testing and Quality Assurance

Comprehensive testing ensures performance consistency:

-

In-Circuit Testing (ICT)

-

Functional Testing

-

X-ray Inspection for hidden solder joints

Final Assembly & Packaging

Assembled boards are integrated into enclosures if required, labeled, and packaged for shipment.

Product Specifications for Turnkey PCB Assembly

| Specification | Details |

|---|---|

| PCB Layers | 1 to 32 layers |

| Board Thickness | 0.4mm to 3.2mm |

| Surface Finish | HASL, ENIG, OSP, Immersion Tin, Hard Gold |

| Minimum Trace Width | 3 mil |

| Minimum Hole Size | 0.1mm |

| Component Package | 0201, QFN, BGA, LGA, CSP |

| Testing Options | ICT, AOI, X-ray, Functional Testing |

| Lead Time | 3-15 working days based on complexity |

This technical flexibility makes turnkey PCB assembly an ideal choice for both prototype development and mass production runs.

Why Choose Turnkey PCB Assembly Over Traditional PCB Assembly

Modern electronics require smaller, faster, and more reliable circuit boards, making turnkey assembly a strategic advantage.

Cost Efficiency

Because turnkey providers manage sourcing and manufacturing, they negotiate better bulk pricing on components and materials. This is particularly beneficial for startups aiming to minimize upfront costs.

Risk Reduction

By using a single provider, you avoid sourcing counterfeit or obsolete components, a growing issue in today’s electronics supply chain.

Prototyping and Small Batch Production

Turnkey assembly accelerates rapid prototyping cycles, enabling engineers to test and iterate designs faster.

Quality Assurance at Every Step

With integrated inspection systems, defects are detected early, ensuring consistent high-quality boards.

Turnkey PCB Assembly vs. Traditional PCB Assembly

| Feature | Turnkey PCB Assembly | Traditional PCB Assembly |

|---|---|---|

| Component Sourcing | Handled by provider | Managed by client |

| Lead Time | Shorter due to streamlined workflow | Longer due to multiple vendors |

| Cost Control | Lower, thanks to bulk purchasing | Higher, with multiple markup points |

| Risk Management | Lower risk of counterfeit parts | Higher risk if sourcing independently |

| Quality Assurance | Integrated testing & inspection | Varies by supplier |

Turnkey PCB Assembly FAQ

Q1: What does “turnkey” mean in PCB assembly?

A turnkey service manages everything — from component sourcing and PCB fabrication to assembly, testing, and delivery. You only provide your design files and requirements.

Q2: Can turnkey PCB assembly handle complex HDI and multilayer boards?

Yes. Modern providers support up to 32-layer PCBs, microvias, blind and buried vias, and BGA packages for high-density applications.

Choosing the Right Turnkey PCB Assembly Partner

Selecting the right provider is crucial to ensure reliable quality, fast turnaround, and cost efficiency. Here’s what to consider:

Evaluate Manufacturing Capabilities

Look for providers with:

-

Advanced SMT and through-hole equipment

-

Capability to handle high-frequency, rigid-flex, and HDI boards

-

Automated inspection and testing systems

Check Supply Chain Strength

A reliable provider maintains relationships with authorized distributors to ensure genuine components and stable pricing.

Consider Engineering Support

Turnkey partners should offer:

-

Design for Manufacturing (DFM) review

-

Design for Testability (DFT) suggestions

-

Support for prototyping and full-scale production

Certifications and Quality Standards

Ensure compliance with:

-

ISO 9001 (Quality Management)

-

ISO 13485 (Medical Device Manufacturing)

-

IATF 16949 (Automotive Electronics)

-

RoHS and REACH (Environmental Standards)

Turnkey PCB Assembly FAQ

Q3: How long does turnkey PCB assembly take from start to finish?

For simple two-layer boards, it can take as little as 3-5 working days. For complex multilayer designs, production may require 2-3 weeks.

Q4: Does turnkey PCB assembly support small-volume orders?

Absolutely. Many providers specialize in low-volume prototyping before scaling to mass production.

Turnkey PCB assembly has transformed the electronics manufacturing landscape by providing a faster, cost-effective, and highly reliable approach to PCB production. From component sourcing to final delivery, a single provider manages the entire process, ensuring superior quality and reduced lead times.

Fanway has established itself as a trusted leader in turnkey PCB assembly services, offering advanced manufacturing capabilities, rigorous quality control, and unmatched supply chain strength. Whether you need rapid prototyping or high-volume production, Fanway delivers precision, reliability, and scalability.

Ready to streamline your PCB manufacturing process?

Contact us today to discuss your turnkey PCB assembly needs and get a tailored solution for your project.