Why Is Turnkey PCB Assembly the Smartest Choice for Modern Electronics Manufacturing?

2025-11-24

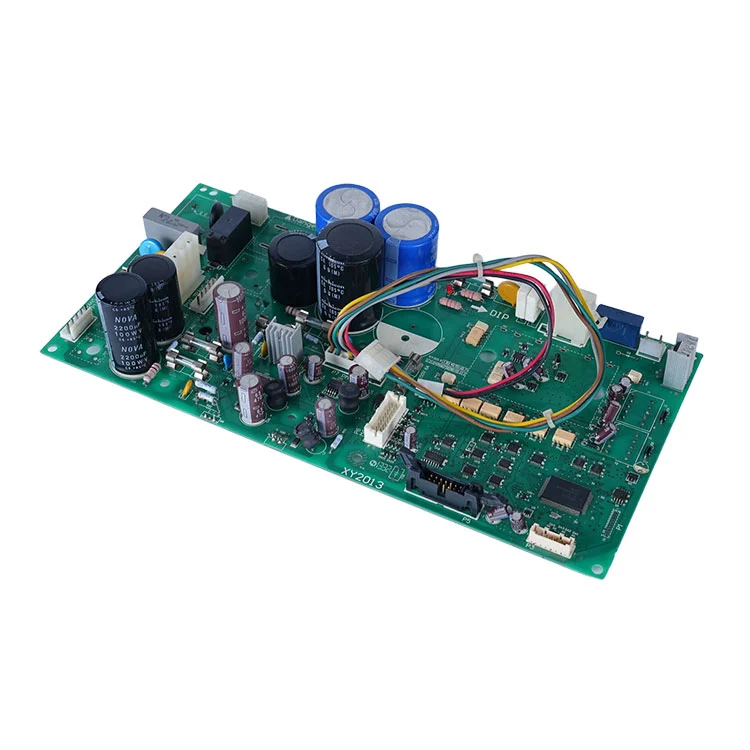

Turnkey PCB Assembly has become one of the most efficient solutions for companies seeking fast production, reliable quality, and integrated services in today's electronics industry. As a manufacturer from Shenzhen Fanway Technology Co., Ltd, I understand the growing demand for a seamless process that combines component sourcing, PCB fabrication, assembly, and testing into one streamlined solution. In this article, we explore the functions, effectiveness, and importance of Turnkey PCB Assembly while presenting clear structure, professional insights, and practical value for global buyers.

What Is Turnkey PCB Assembly?

Turnkey PCB Assembly refers to a complete manufacturing service where the supplier handles every production step—from PCB manufacturing to component procurement, assembly, quality inspection, and logistics. Shenzhen Fanway Technology Co., Ltd provides full-process support that helps customers reduce project complexity and focus more on product innovation.

Key Functions of Turnkey PCB Assembly

-

All-in-one production management

-

Component sourcing and inventory control

-

High-precision SMT & THT assembly

-

Complete electrical testing & inspection

-

Optimized lead time with lower overall cost

Technical Parameters Overview

| Parameter Item | Description |

|---|---|

| PCB Layers | 1–24 layers |

| PCB Material | FR4, Rogers, Aluminum, HDI |

| Min. Trace/Space | 3/3 mil |

| Copper Thickness | 1–4 oz |

| Assembly Type | SMT, THT, Mixed |

| Testing Options | AOI, X-ray, ICT, Functional Tests |

| Service Model | Full Turnkey / Partial Turnkey |

How Does Turnkey PCB Assembly Work?

1. Streamlined Workflow

A typical workflow includes PCB fabrication → Component sourcing → Assembly → Testing → Shipping. With Turnkey PCB Assembly, customers receive consistent manufacturing quality from a unified process.

2. Effective Integration

I have noticed that combining procurement, assembly, and testing in one factory significantly reduces communication errors and delays. This leads to better performance and faster delivery.

3. Reduced Cost and Faster Lead Time

Manufacturers such as Shenzhen Fanway Technology Co., Ltd can negotiate lower component prices, ensure stable supply chains, and shorten overall production time.

What Is the Actual Effect of Turnkey PCB Assembly?

Turnkey solutions create visible improvements in production efficiency. Here are the major effects:

-

Higher assembly accuracy with professional SMT lines

-

Stable quality control supported by full-process inspection

-

Lower total cost due to centralized sourcing and optimized production

-

Rapid prototyping enabling faster product launches

-

Better IP protection since all steps stay within one supplier

Why Is Turnkey PCB Assembly Important for Modern Projects?

1. Ensures product reliability

By integrating testing methods like AOI and X-ray, the final PCB meets strict industrial standards.

2. Reduces project risks

Since everything is handled by one experienced team, risk of component mismatch, production delay, and quality inconsistency is significantly lower.

3. Enhances manufacturing flexibility

From prototypes to mass production, Turnkey PCB Assembly adapts easily to customer demands.

Three Q&A

Q1: Why do I prefer Turnkey PCB Assembly for complex projects?

A1: Because it helps me manage time, reduce errors, and receive consistent product quality through a unified process.

Q2: How does Shenzhen Fanway Technology Co., Ltd guarantee the reliability of Turnkey PCB Assembly?

A2: We conduct strict AOI, X-ray, and functional testing during every stage, ensuring stable and long-lasting performance.

Q3: Can Turnkey PCB Assembly shorten my product development cycle?

A3: Yes, I can complete prototypes faster thanks to integrated production, flexible sourcing, and professional technical support.

The Overall Importance and Role of Turnkey PCB Assembly

Turnkey PCB Assembly plays a key role in helping global customers achieve competitive advantages in electronics manufacturing. It simplifies production, accelerates time-to-market, and guarantees stable quality. For companies seeking a reliable partner, Shenzhen Fanway Technology Co., Ltd offers comprehensive one-stop PCB solutions that combine advanced equipment, strict quality control, and efficient supply chain management.

If you need fast delivery, stable quality, and professional one-stop PCB assembly service, contact us today to start your next project with Shenzhen Fanway Technology Co., Ltd.