Why Is the Isola High Frequency Board the Key to Next-Generation Electronic Performance?

2025-10-24

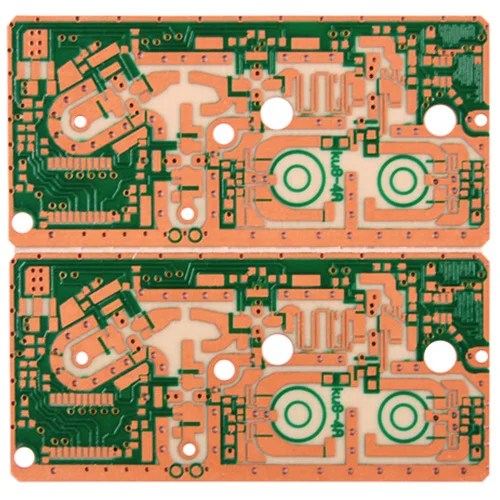

In today's fast-evolving electronics industry, the demand for higher speed, better signal integrity, and superior performance has made material selection more critical than ever. Among the leading materials in this field, the Isola High Frequency Board stands out as a trusted solution for engineers and manufacturers who seek excellence in RF and microwave applications. Designed with advanced resin systems and precise dielectric control, this material ensures reliability, consistency, and unmatched performance across various industries, from telecommunications to automotive radar systems.

What Is an Isola High Frequency Board?

The Isola High Frequency Board is a specialized PCB substrate engineered for high-speed digital and RF applications. It is designed to minimize signal loss and phase distortion, ensuring that data transmission remains accurate even at very high frequencies. These boards are made using advanced glass fabrics and resin systems that deliver low dielectric constant (Dk) and dissipation factor (Df), making them ideal for high-performance circuits.

Below is a simple parameter overview of commonly used Isola materials:

| Parameter | Typical Value | Description |

|---|---|---|

| Dielectric Constant (Dk) | 3.38 – 3.48 | Ensures signal integrity and speed |

| Dissipation Factor (Df) | 0.0027 – 0.0035 | Indicates low signal loss |

| Glass Transition Temperature (Tg) | ≥ 200°C | Provides thermal stability |

| Frequency Range | Up to 77 GHz | Suitable for radar and 5G |

| Material Type | PTFE / Ceramic / Hydrocarbon Resin | High-frequency performance base |

Why Is the Isola High Frequency Board So Important in Modern Electronics?

In high-frequency circuits, even the smallest signal distortion can lead to malfunction or loss of data accuracy. This is why the Isola High Frequency Board plays such a crucial role — it offers outstanding electrical consistency and heat resistance. Its low Dk and Df values reduce signal attenuation, allowing electronic devices to transmit signals more cleanly and efficiently.

I once had a client from the communication industry ask:

Q1: Why should we choose an Isola High Frequency Board instead of a regular FR4 board?

A1: The difference lies in precision and performance. FR4 materials work fine for low-frequency designs, but they cannot handle the high-speed, low-loss requirements of 5G, radar, or satellite communication. Isola materials are specifically engineered to provide stable signal transmission, low dielectric loss, and excellent temperature performance — all vital for advanced electronics.

Main Functions and Effects

The Isola High Frequency Board serves multiple functions that make it indispensable in high-end circuit design:

-

Enhanced Signal Integrity: Maintains stable impedance and minimizes crosstalk.

-

Thermal Management: Handles high temperatures and reduces warpage.

-

Reliable Mechanical Stability: Offers consistent layer bonding and minimal expansion.

-

Low Loss Factor: Supports fast data transmission without distortion.

-

Durability: Withstands harsh environmental conditions and long-term operation.

When used in high-performance applications like radar detection, satellite communication, and 5G base stations, the result is clear — faster data flow, higher reliability, and extended lifespan of devices.

Applications Across Industries

The Isola High Frequency Board has wide-ranging applications, including:

-

5G Base Stations – for high-speed communication and stable data transfer.

-

Automotive Radar Systems – for precise object detection and safety enhancement.

-

Aerospace and Defense – where stable, high-frequency signals are essential.

-

Medical Imaging Equipment – ensuring signal clarity and performance accuracy.

-

High-Speed Routers and Servers – improving data transfer rates and efficiency.

Why Choose Guangdong Viafine PCB LIMITED?

At Guangdong Viafine PCB LIMITED, we specialize in manufacturing Isola High Frequency Boards with precision and care. Our advanced production facilities ensure every board meets stringent quality standards for dielectric control, copper adhesion, and thermal stability.

We provide complete PCB solutions from design support to final production, tailored for high-frequency and high-speed applications. Our engineering team ensures consistent performance, fast turnaround, and professional guidance throughout your project.

One More Practical Question You Might Have

Q2: How does an Isola High Frequency Board improve product performance in 5G systems?

A2: It allows signals to travel with minimal loss and distortion, meaning faster data transmission and lower latency. In 5G applications, even slight signal degradation can lead to communication errors. Using Isola boards guarantees signal consistency, ensuring devices can operate at their designed performance level.

Importance and Value in the Industry

The introduction of Isola High Frequency Boards marks a significant technological shift for electronic manufacturing. Their low dielectric loss and thermal reliability make them the cornerstone of next-generation RF and microwave design. Without them, innovations like self-driving cars, advanced IoT networks, and satellite communication systems would face serious limitations.

I often remind my clients:

Q3: What's the long-term benefit of using Isola High Frequency Board materials?

A3: In the long run, these boards save costs by improving efficiency, reducing maintenance, and extending product life. Their consistent performance across temperature and frequency ranges ensures devices remain reliable under demanding conditions — a value that standard materials simply cannot match.

Final Thoughts

The Isola High Frequency Board is more than just a PCB material — it's the foundation for the future of high-speed communication, intelligent mobility, and precision electronics. Whether you're developing next-generation radar systems or advanced telecommunication equipment, choosing Isola materials ensures stability, reliability, and long-term performance.

At Guangdong Viafine PCB LIMITED, we are committed to delivering high-quality Isola-based PCB solutions that meet the evolving demands of global technology industries.

If you're ready to take your high-frequency designs to the next level, contact us today — our engineering experts will help you find the best solution for your project's success.