Why Is SMT PCB Assembly the Key to Modern Electronics Manufacturing?

2025-10-29

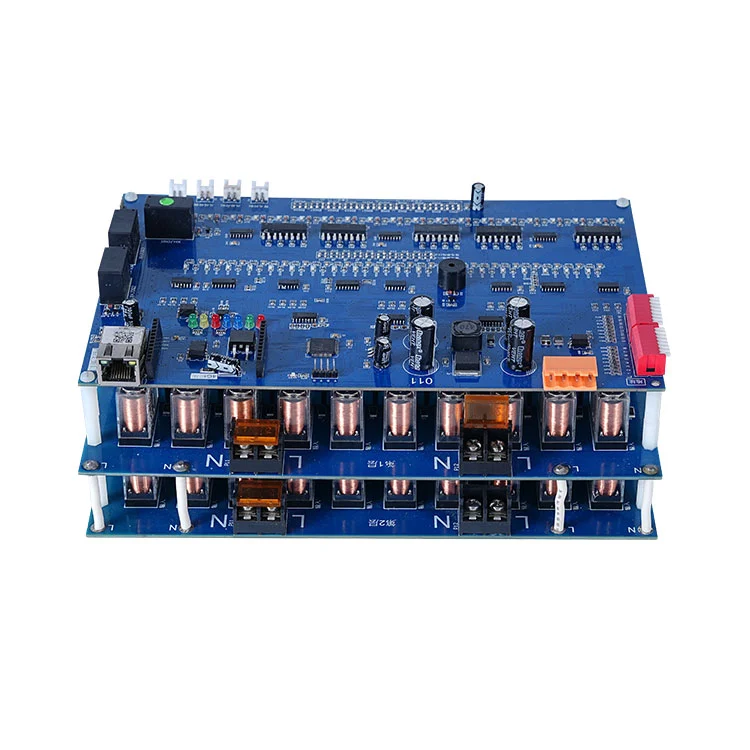

In today's rapidly advancing electronics industry, SMT PCB Assembly (Surface Mount Technology Printed Circuit Board Assembly) has become the foundation for high-efficiency, high-density electronic product manufacturing. As a professional manufacturer, Shenzhen Fanway Technology Co., Ltd. provides complete SMT PCB Assembly solutions that integrate precision engineering, quality assurance, and fast delivery. From consumer electronics to industrial automation, SMT technology ensures compact design, reliability, and cost efficiency.

What Is SMT PCB Assembly and How Does It Work?

SMT PCB Assembly is the process of mounting electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole methods, SMT allows for miniaturized designs and high-speed automated assembly. The main process includes solder paste printing, component placement, reflow soldering, and inspection.

Key Advantages:

-

High efficiency – Automated machines place thousands of components per hour.

-

Compact design – Ideal for lightweight and high-density electronics.

-

Enhanced performance – Improved electrical performance and signal integrity.

-

Cost reduction – Fewer drilling steps and lower material consumption.

Technical Parameters of SMT PCB Assembly

| Parameter | Specification |

|---|---|

| Component size range | 01005 to 45×45 mm |

| PCB size range | 50×50 mm – 510×460 mm |

| Placement accuracy | ±0.03 mm |

| Solder paste thickness | 0.12–0.25 mm |

| Reflow soldering temperature | 220–250°C |

| Supported components | IC, BGA, QFN, CSP, resistor, capacitor |

| Testing methods | AOI, X-ray, ICT, Functional Test (FCT) |

These parameters highlight Shenzhen Fanway Technology Co., Ltd.'s capability to handle complex, high-precision assemblies that meet international quality standards.

Why Is SMT PCB Assembly So Important?

The importance of SMT PCB Assembly lies in its ability to meet the market's demand for smaller, faster, and smarter devices. By using automated pick-and-place systems and reflow ovens, we can ensure consistent quality while significantly increasing production efficiency. This makes it indispensable for applications such as smartphones, automotive electronics, LED lighting, and medical devices.

Moreover, SMT reduces manual intervention, minimizing defects and ensuring long-term reliability—a key advantage for manufacturers seeking consistent performance across large production batches.

What Are the Effects and Benefits in Real Applications?

When I first implemented SMT PCB Assembly in our production line, I was impressed by the improvement in yield rates and production speed. The overall efficiency increased by more than 30%, while solder joint quality and component stability reached a higher standard.

The technology's impact extends beyond efficiency—it also enhances product aesthetics and durability. Devices assembled with SMT are lighter, more compact, and capable of handling complex circuit functions without sacrificing quality or performance.

Frequently Asked Questions (Q&A)

Q1: Why should I choose SMT PCB Assembly for my products?

A1: SMT PCB Assembly enables high-density designs, superior reliability, and reduced production costs, making it ideal for any modern electronic product.

Q2: How does Shenzhen Fanway Technology Co., Ltd. ensure quality during SMT assembly?

A2: We conduct 100% inspection through AOI and X-ray testing to ensure each board meets IPC and ISO standards before delivery.

Q3: Can SMT PCB Assembly handle both prototype and mass production orders?

A3: Yes, we offer flexible production capabilities that support small-batch prototypes and large-scale manufacturing with consistent quality control.

The Role and Value of Shenzhen Fanway Technology Co., Ltd.

As a trusted provider, Shenzhen Fanway Technology Co., Ltd. delivers one-stop SMT PCB Assembly services—from PCB design and material procurement to final assembly and functional testing. Our technical team combines years of industry experience with advanced production equipment, ensuring every project achieves precision and reliability.

We also provide fast turnaround services and competitive pricing, enabling our customers to bring products to market faster and more effectively. Whether it's for IoT devices, consumer electronics, or industrial equipment, our SMT solutions guarantee exceptional performance and durability.

Conclusion

In an era where every millimeter of space and every second of production time counts, SMT PCB Assembly has become the heart of modern electronic manufacturing. Partnering with Shenzhen Fanway Technology Co., Ltd. means choosing quality, innovation, and efficiency.

If you're looking for a reliable SMT PCB Assembly service provider that can bring your electronic designs to life with precision and care — contact us today to discuss your next project!