Why Is Choosing the Right Home Appliance PCBA So Important for Product Performance?

2025-08-14

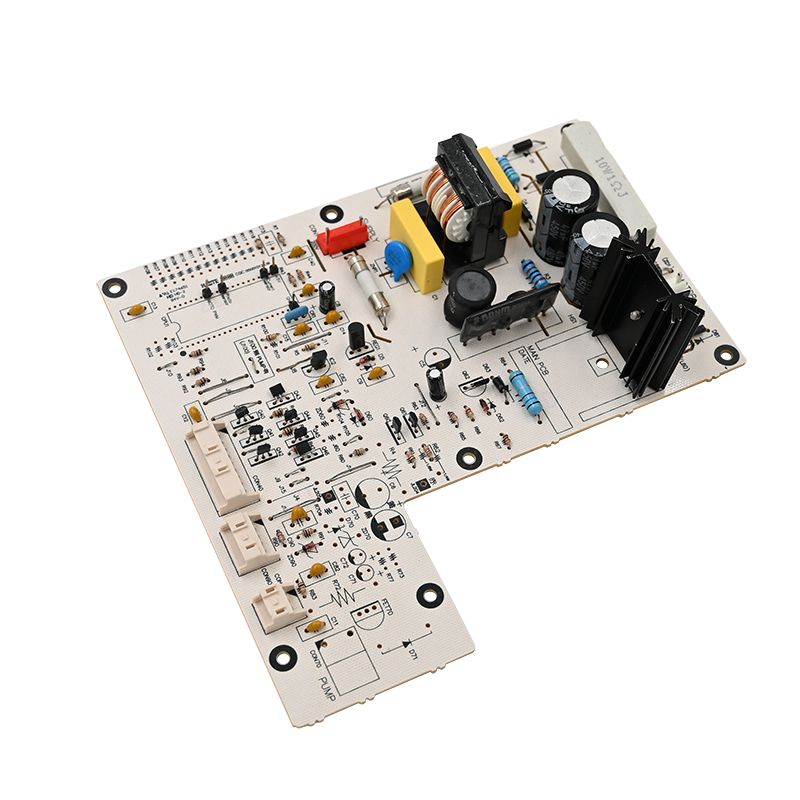

In the rapidly evolving home appliance industry, Home Appliance PCBA (Printed Circuit Board Assembly) plays a crucial role in ensuring that appliances operate efficiently, reliably, and safely. From refrigerators to washing machines, from air conditioners to microwaves, every appliance relies on a well-designed PCBA to manage functions, control power, and communicate between components.

Our engineering expertise ensures that each Home Appliance PCBA is designed to meet strict industry standards while also delivering exceptional performance. Unixplore Electronics Co., Ltd specializes in providing tailored PCBAs for various home appliance applications, meeting both mass production demands and custom design requirements.

Key Functions and Applications

A Home Appliance PCBA acts as the brain of your appliance, performing multiple critical roles:

-

Power Management – Regulates voltage and current to protect components.

-

Signal Processing – Transmits and processes electronic signals for operational control.

-

User Interface Control – Manages buttons, touch screens, and display modules.

-

Sensor Integration – Supports temperature, pressure, and motion sensors for smart appliances.

-

Safety Features – Includes protection circuits for overcurrent, short circuits, and overheating.

Product Parameters

Our Home Appliance PCBA products are manufactured to meet precise technical requirements. Below is a general specification overview:

Main Parameters:

-

Board Material: FR4, CEM-1, or customized

-

Layer Count: 1–12 layers

-

Copper Thickness: 1–3 oz

Home Appliance PCBA Specification Table

| Parameter | Specification Options |

|---|---|

| Board Material | FR4, CEM-1, Custom |

| Layers | 1–12 |

| Copper Thickness | 1–3 oz |

| Surface Finish | HASL, ENIG, OSP, Immersion Silver |

| Assembly Type | Single-sided, Double-sided, Mixed |

| Component Size Range | 01005 to large connectors |

| Testing Methods | ICT, AOI, Functional Test |

| Operating Temperature | -20°C to 85°C or customized |

Advantages of Our Home Appliance PCBA Solutions

-

Custom Design Capability – Tailored layouts and functions for your specific appliance model.

-

Scalable Production – From prototype runs to large-scale manufacturing.

-

Strong Supplier Network – High-quality electronic components sourced from trusted partners.

-

Compliance and Certification – Fully RoHS-compliant and CE-certified designs.

-

Fast Turnaround – Optimized production lines to meet urgent project timelines.

Home Appliance PCBA – FAQ

Q1: What factors should I consider when choosing a Home Appliance PCBA?

A1: Consider compatibility with your appliance's power and control requirements, material quality, environmental compliance, and testing standards. A good PCBA should also have proper heat dissipation, robust protective circuits, and high-quality components.

Q2: How does a Home Appliance PCBA improve appliance efficiency?

A2: It ensures accurate signal control, optimal power distribution, and reduced energy loss. Advanced PCBAs integrate intelligent algorithms that help appliances adjust operations based on usage patterns, leading to energy savings and better performance.

Q3: What testing methods are used for Home Appliance PCBA?

A3: We use a combination of ICT (In-Circuit Testing) for electrical integrity, AOI (Automated Optical Inspection) for solder joint quality, and functional testing to verify operational performance under simulated real-world conditions.

Contact Unixplore Electronics Co., Ltd

Unixplore Electronics Co., Ltd is committed to delivering Home Appliance PCBA solutions that combine cutting-edge design with uncompromising quality. Whether you need a custom prototype or a high-volume production run, we have the expertise and resources to bring your project to life.

Contact us today to discuss your requirements and discover how our PCBAs can elevate your home appliance products.