Why Is Ceramic PCB Redefining High-Performance Electronics?

2025-11-28

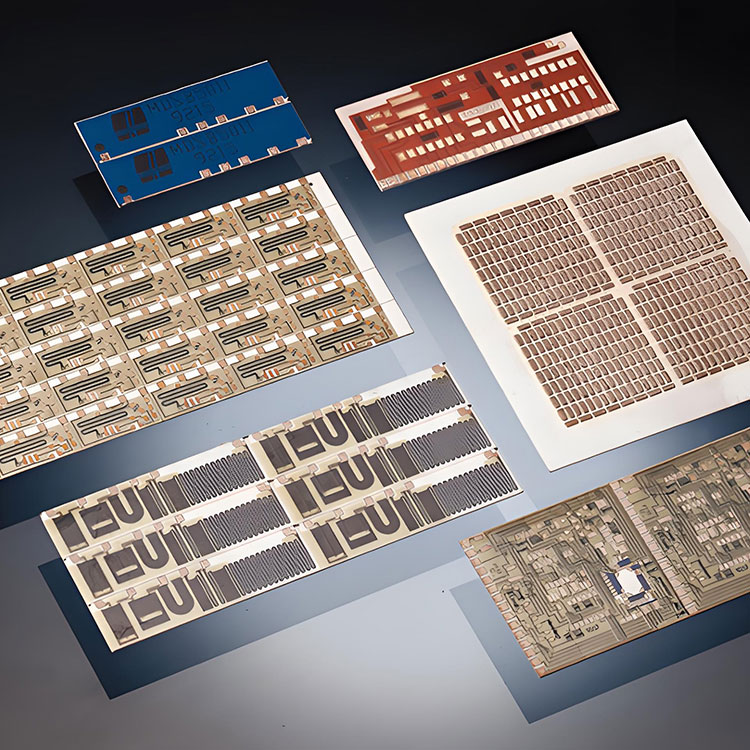

Ceramic PCB (Ceramic Printed Circuit Board) has emerged as one of the most influential materials in advanced electronic engineering due to its exceptional heat resistance, high thermal conductivity, electrical insulation, and structural stability. Unlike traditional FR4 or metal-core boards, Ceramic PCB leverages materials such as alumina (Al₂O₃), aluminum nitride (AlN), and silicon nitride (Si₃N₄) to support extreme-performance applications in aerospace, automotive power modules, LED lighting, telecom base stations, military systems, and high-frequency devices.

What Is Ceramic PCB and Why Is It Essential for High-Power Technologies?

Ceramic PCB is a circuit board made with ceramic substrates rather than fiberglass or metal. These ceramic substrates exhibit superior thermal conductivity and can withstand much higher temperatures than conventional materials. As high-power semiconductor modules and miniaturized devices become mainstream, the industry increasingly relies on Ceramic PCB to deliver stable electrical performance under extreme conditions.

Why Ceramic PCB Stands Out

-

It dissipates heat far more efficiently than FR4 or metal-core PCBs.

-

Ceramic materials maintain structural and electrical stability in harsh environments.

-

They are ideal for high-frequency, high-voltage, and high-power applications.

-

They reduce system size by eliminating bulky heat sinks or thermal pads.

-

They enable higher reliability and longer product lifespan.

How Ceramic PCB Enhances Industrial Performance: Key Parameters and Technical Advantages

To better understand the capabilities of Ceramic PCB, the following table summarizes typical parameters for commonly used materials. These specifications represent industry-standard ranges that manufacturing professionals evaluate when selecting ceramic substrates.

Ceramic PCB Technical Parameters

| Parameter | Alumina (Al₂O₃) | Aluminum Nitride (AlN) | Silicon Nitride (Si₃N₄) |

|---|---|---|---|

| Thermal Conductivity | 20–30 W/m·K | 150–180 W/m·K | 70–90 W/m·K |

| Dielectric Strength | 15–20 kV/mm | 12–15 kV/mm | 10–12 kV/mm |

| Operating Temperature | Up to 1,500°C | Up to 1,000°C | Up to 1,200°C |

| Thermal Expansion Coefficient | 6–8 ppm/°C | 4.5 ppm/°C | 2.6–3 ppm/°C |

| Mechanical Strength | High | Medium | Very High (ideal for shock loads) |

| Common Applications | LEDs, sensors, RF parts | Power modules, lasers | Automotive inverters, EVs, aerospace |

Why Industries Prefer Ceramic PCB: In-Depth Benefits

Thermal Performance

Ceramic substrates dissipate heat directly through the board material, providing a stable platform for high-power ICs, MOSFETs, laser diodes, and GaN/SiC semiconductors. As electronics become more compact and powerful, heat dissipation becomes the key limiting factor—Ceramic PCB solves this bottleneck by offering consistent thermal pathways that ensure long-term reliability.

Electrical Insulation and High Voltage Resistance

Ceramic materials provide excellent dielectric properties, allowing the board to handle high-voltage environments without breakdown. This advantage is crucial for automotive power modules, EV charging systems, and 5G base station signal processors.

Chemical, Moisture, and Corrosion Resistance

Ceramic substrates are inherently resistant to oxidation, moisture absorption, and chemical reactions, making them suitable for aerospace controls, medical devices, outdoor telecom equipment, and military-grade electronics.

Structural Stability Under Extreme Stress

Silicon nitride Ceramic PCB, in particular, is designed for demanding mechanical stresses. This material maintains strength under vibration, shock, and thermal cycling—key requirements in electric vehicles and aircraft.

Miniaturization Without Performance Loss

Ceramic PCB enables thinner, smaller configurations while sustaining higher power density. This aligns perfectly with the global trend toward device miniaturization and energy efficiency.

How Ceramic PCB Is Manufactured: A High-Precision Process

Ceramic PCB production involves advanced material processes that ensure stable electrical and thermal performance:

Direct Bonded Copper (DBC) Technology

Copper is bonded directly onto ceramic under high temperature and oxygen-rich conditions.

Advantages: strong adhesion, excellent thermal cycling performance.

Direct Copper Plating (DPC) Process

Copper is plated onto a ceramic substrate using sputtering and chemical deposition.

Advantages: high precision, ideal for fine-line circuits and RF applications.

Thick-Film and Thin-Film Ceramic PCB

These technologies deposit conductive layers via screen printing or vacuum deposition.

Advantages: suitable for high-frequency and sensor applications.

What Applications Benefit Most From Ceramic PCB?

LED and Laser Lighting Systems

High-power LEDs depend on Ceramic PCB to manage heat effectively, ensuring longer brightness lifespan and color stability.

Automotive Electronics and EV Power Systems

Ceramic PCB is widely used in:

-

Battery management systems

-

IGBT modules

-

On-board chargers (OBC)

-

Drive inverters

Their high thermal cycling capability makes them indispensable in EV engineering.

Telecom, GPS, and 5G Infrastructure

High-frequency signal integrity and low dielectric loss make Ceramic PCB ideal for:

-

Base station modules

-

RF antennas

-

Satellite communication systems

Aerospace and Defense Systems

Ceramic PCB withstands extreme environments, mechanical shock, radiation exposure, and vacuum conditions.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan difference between Ceramic PCB and traditional FR4 boards?

A1: Ceramic PCB can last significantly longer than FR4, especially in high-power or high-heat environments. FR4 suffers from heat-induced degradation, delamination, and reduced dielectric performance. Ceramic PCB maintains stable performance even when exposed to temperatures above 500–1,000°C. In high-power modules such as SiC/GaN systems, Ceramic PCB may last 5–10 times longer, depending on usage and thermal load.

Q2: Why is Ceramic PCB more expensive and how does it justify the cost?

A2: Ceramic PCB uses advanced materials and high-precision manufacturing methods. The cost is justified by:

-

Reduced need for additional heat dissipating structures

-

Longer device lifespan

-

Enhanced reliability in mission-critical applications

-

Improved efficiency in high-frequency systems

-

Reduction in overall system size and complexity

For industries where downtime is costly or reliability is non-negotiable, Ceramic PCB provides better long-term value.

Future Trends: Where Is Ceramic PCB Technology Heading?

Integration With SiC and GaN Power Devices

Wide-bandgap semiconductors demand high thermal performance. Ceramic PCB is becoming the industry standard for these modules.

Growth Driven by Electric Vehicles

As EV power systems require high-voltage and high-efficiency modules, silicon nitride Ceramic PCB will continue to gain dominance due to its mechanical strength and thermal reliability.

Miniaturization and High-Density Circuit Packaging

Future electronics will pack more power into smaller footprints. Ceramic PCB will bridge the gap between advanced heat management and ultra-compact integration.

Expansion of 5G, 6G, and Future Communication Technologies

Low dielectric loss ceramics will support antenna miniaturization and higher signal frequencies, pushing Ceramic PCB into mainstream telecom manufacturing.

Sustainable Materials and Eco-Friendly Processing

As environmental expectations rise, ceramic materials—being stable and long-lasting—offer a more sustainable alternative to traditional laminates that degrade more easily.

Conclusion: Why Choose Ceramic PCB Today and How Hayner Supports Global Projects

Ceramic PCB is transforming high-power and high-frequency electronics by delivering exceptional thermal conductivity, outstanding electrical insulation, mechanical durability, and long-term reliability. As industries push toward higher power density, smarter devices, faster communication, and energy-efficient systems, Ceramic PCB has become a cornerstone technology powering the next generation of engineering innovations.

With extensive manufacturing expertise and a deep understanding of global industry standards, Hayner provides high-quality Ceramic PCB solutions that meet the demands of LED systems, EV power modules, aerospace controls, RF communication networks, and advanced industrial systems. For businesses seeking durable, high-performance PCB technology capable of supporting next-generation applications, Hayner offers comprehensive technical support, precision production, and reliable delivery.

To explore Ceramic PCB solutions tailored to your project requirements, contact us and receive expert guidance for your upcoming designs.