Why Is a Window Package High Power Laser Diode Becoming the Quiet Upgrade Behind Stable High-Power Systems?

2026-01-12

When I first started evaluating high-power laser components for industrial and photonics projects, I noticed a recurring problem that engineers rarely talk about openly: stability issues that appear only after months of operation. This was exactly the context in which Wavespectrum gradually entered my field of view, not through marketing noise, but through conversations about reliability. As I dug deeper, one component kept resurfacing as a practical solution rather than a buzzword — the Window Package High Power Laser Diode.

What surprised me was how often this design quietly solved problems that standard packages struggled with, especially in demanding environments where contamination, optical feedback, and thermal stress tend to accumulate over time.

What Makes a Window Package High Power Laser Diode Different in Real-World Use?

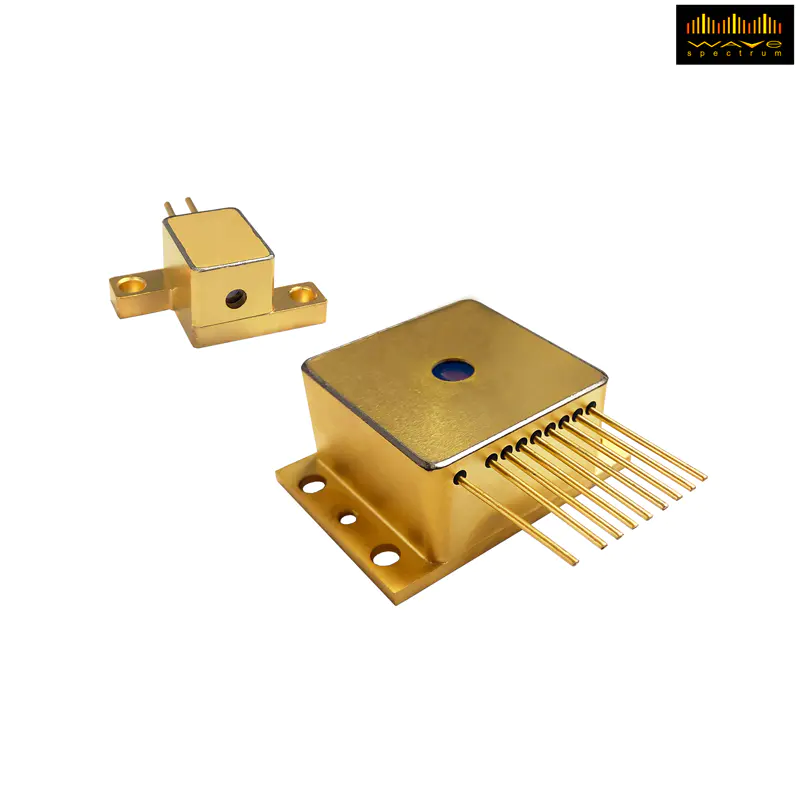

At a glance, the structure looks simple, but in practice the window package plays a critical role. By introducing a protective optical window between the chip and the external environment, a Window Package High Power Laser Diode adds a layer of control that traditional open-facet designs simply cannot offer.

- It physically isolates the laser facet from dust, moisture, and vapor contamination.

- It reduces the risk of catastrophic optical damage caused by back reflections.

- It improves long-term wavelength and power stability under continuous operation.

From my experience, these advantages become most visible not on day one, but after thousands of operating hours.

Why Do Long-Term Users Care About Optical Window Protection?

Many customers I have spoken with initially focus on output power numbers. However, once systems are deployed, their concerns shift. Downtime, maintenance cycles, and output drift start to matter far more than peak specifications.

This is where a Window Package High Power Laser Diode changes the conversation. The window acts as a sacrificial and stabilizing interface, preserving the integrity of the emitting facet even in harsh operating conditions.

| Operational Concern | Impact Without Window Package | Impact With Window Package |

|---|---|---|

| Facet contamination | Gradual power degradation | Significantly reduced risk |

| Back reflection sensitivity | Higher failure probability | Improved optical isolation |

| Maintenance frequency | Unpredictable service intervals | More stable long-term operation |

How Does Thermal Management Benefit From a Window Package Design?

Thermal stress is often underestimated when selecting laser diodes. In high-power applications, even minor thermal gradients can accelerate aging. A well-designed Window Package High Power Laser Diode supports more controlled heat dissipation by stabilizing the optical interface and reducing localized hot spots caused by contamination or feedback.

In practice, this translates into more predictable performance under continuous wave or pulsed operation, especially in fiber-coupled and free-space systems.

Where Does a Window Package High Power Laser Diode Fit Best in Modern Systems?

Based on real deployment feedback, these diodes are particularly valued in applications where uptime and consistency matter more than marginal cost savings.

- Industrial material processing systems running extended duty cycles

- Medical and scientific instruments requiring output repeatability

- Fiber-coupled laser modules exposed to complex optical paths

- OEM systems designed for global deployment in varied environments

In each of these cases, the Window Package High Power Laser Diode acts less like an upgrade and more like an insurance policy against hidden operational risks.

Why Are Engineers Moving Toward Window Package Solutions Instead of Retrofits?

Retrofitting protection into an existing optical system often introduces new alignment challenges and additional losses. Choosing a Window Package High Power Laser Diode from the start simplifies system design and reduces the need for downstream corrective measures.

From my perspective, this proactive approach aligns better with how modern laser systems are expected to perform — reliably, continuously, and with minimal intervention.

Is a Window Package High Power Laser Diode Worth Considering for Your Next Design?

If your priority is short-term cost alone, the difference may not seem dramatic. But if you are responsible for long-term performance, customer satisfaction, and system reputation, the value becomes clearer. A thoughtfully engineered Window Package High Power Laser Diode supports cleaner optics, steadier output, and fewer surprises after deployment.

If you are exploring how this technology could fit into your application, or if you want to discuss performance trade-offs in more detail, we encourage you to contact us and leave an inquiry. The right laser diode choice today can prevent many operational headaches tomorrow.