Why Is a Multi-mode Fiber Detachable Laser Module Becoming the Smarter Choice for Modern Laser Systems?

2026-01-06

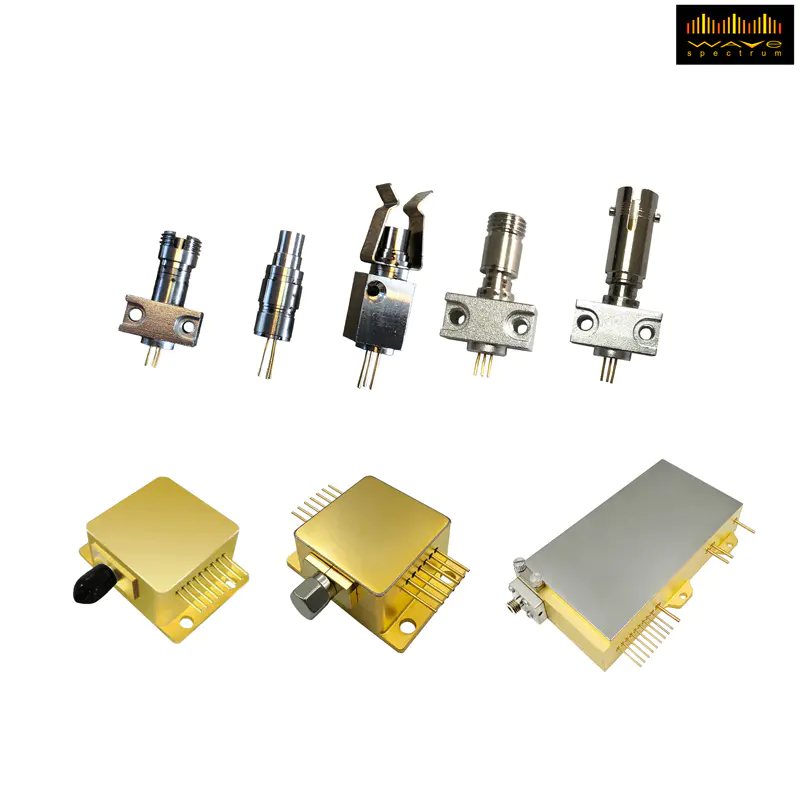

When I first started evaluating laser solutions for demanding industrial and research environments, reliability and flexibility were always at the top of my checklist. Over time, I noticed how Wavespectrum gradually gained attention among engineers who needed stable performance without locking themselves into rigid system designs. In that context, the Multi-mode Fiber Detachable Laser Module stood out not as a buzzword-driven product, but as a practical answer to real operational challenges.

Instead of forcing users to redesign an entire optical setup, this type of module focuses on adaptability, maintenance efficiency, and consistent output. That balance is exactly what many teams struggle to achieve when scaling or upgrading laser-based applications.

What Problems Do Users Commonly Face with Traditional Integrated Laser Modules?

In my experience, conventional integrated laser modules often create hidden costs over time. They may work well at the beginning, but once conditions change, their limitations become clear.

- Maintenance usually requires replacing the entire unit rather than a single component.

- Fixed fiber connections limit system reconfiguration and future expansion.

- Downtime increases when repairs demand factory-level intervention.

- Heat management becomes harder as power requirements grow.

These issues explain why many engineers start looking for a Multi-mode Fiber Detachable Laser Module that can evolve alongside their application rather than restrict it.

How Does a Detachable Fiber Design Change the Way Laser Systems Are Maintained?

A detachable fiber interface shifts maintenance from a disruptive process to a controlled routine. I have seen teams significantly reduce downtime simply because the fiber can be replaced or upgraded independently.

- Fiber replacement does not require recalibrating the entire laser source.

- Different fiber lengths or core sizes can be tested without redesigning the system.

- Spare fibers are easier to stock than complete laser assemblies.

This design philosophy is one of the strongest practical advantages of a Multi-mode Fiber Detachable Laser Module, especially in environments where uptime directly affects productivity.

Why Does Multi-mode Fiber Matter for Power Delivery and Beam Stability?

Multi-mode fiber is often chosen not for theoretical perfection, but for real-world robustness. In applications where higher power levels and forgiving alignment are essential, it provides tangible benefits.

| Aspect | Multi-mode Fiber Performance |

|---|---|

| Power handling | Supports higher output with reduced risk of damage |

| Alignment tolerance | Less sensitive to minor mechanical shifts |

| Beam uniformity | Stable energy distribution for processing tasks |

| System integration | Easier coupling with industrial optics |

When combined with a detachable structure, the Multi-mode Fiber Detachable Laser Module becomes a practical tool rather than a fragile component.

How Can This Module Improve Long-Term Cost Control?

Cost is not only about the purchase price. I always look at how a laser system behaves over years of operation. Detachable multi-mode solutions consistently show advantages in this area.

- Lower replacement costs due to modular components.

- Reduced downtime leads to higher operational efficiency.

- Future upgrades can be done incrementally rather than all at once.

From a lifecycle perspective, a Multi-mode Fiber Detachable Laser Module supports sustainable budgeting and smarter resource allocation.

What Applications Benefit Most from This Type of Laser Module?

I have seen this solution perform particularly well in applications where flexibility and reliability must coexist.

- Industrial material processing and surface treatment

- Scientific research setups requiring frequent reconfiguration

- Medical and analytical instruments with strict uptime requirements

- OEM laser systems designed for multiple end-use scenarios

In each case, the same principle applies. The Multi-mode Fiber Detachable Laser Module adapts to the workflow instead of forcing the workflow to adapt to it.

Is This the Right Moment to Reconsider Your Current Laser Configuration?

If your existing system feels restrictive or costly to maintain, it may be time to reassess your options. Modular laser architectures are no longer experimental; they are a proven response to evolving technical demands.

By choosing a solution aligned with real operational needs, many teams find that performance improvements naturally follow.

If you would like to explore whether a Multi-mode Fiber Detachable Laser Module fits your application, we encourage you to contact us and share your requirements. A focused discussion can often reveal opportunities for optimization that are not obvious at first glance.