Why Choose Wire Harness for Reliable Electrical Connections?

2025-09-04

In the ever-evolving world of modern technology, wire harnesses have become indispensable components that power our homes, vehicles, factories, and electronic devices. Whether you are in the automotive industry, manufacturing, aerospace, or consumer electronics, understanding what a wire harness is, why it matters, and how it enhances system performance is essential for choosing the right solution for your needs.

What Is a Wire Harness and Why Does It Matter?

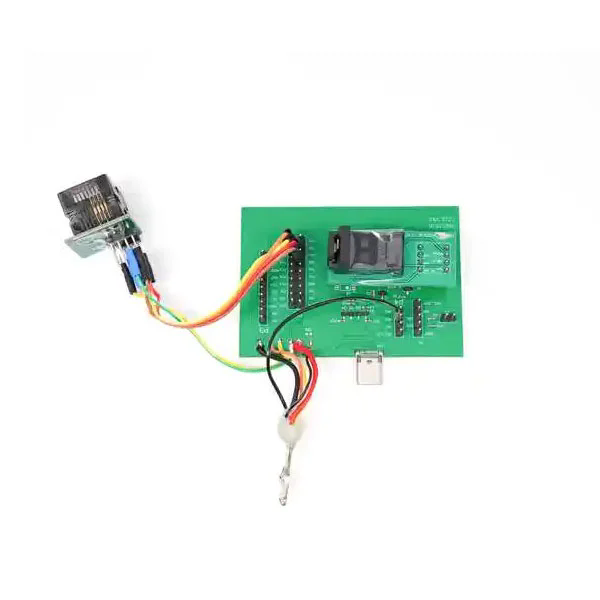

A wire harness, also known as a wiring harness or cable assembly, is an organized bundle of electrical cables or wires that transmit power and signals within a device, machine, or system. Instead of routing individual wires separately, a harness combines them into a single, compact assembly protected by insulating materials such as PVC, rubber, or braided sleeves.

Key Functions of a Wire Harness

-

Electrical Power Transmission – Ensures efficient delivery of energy between components.

-

Signal Communication – Facilitates seamless data transfer within devices and systems.

-

Organization and Space Saving – Prevents messy, tangled wiring and optimizes installation.

-

Protection Against Damage – Shields wires from abrasion, moisture, vibration, and temperature extremes.

-

Enhanced Safety and Reliability – Reduces the risk of short circuits, electrical fires, and system failures.

Without wire harnesses, modern electronics, vehicles, and industrial machines would be bulkier, less reliable, and far more prone to damage.

Applications Across Industries

Wire harnesses are critical in nearly every industry, including:

-

Automotive: Engine wiring, lighting systems, sensors, and infotainment.

-

Aerospace: Flight control systems, cockpit electronics, and navigation equipment.

-

Industrial Automation: Robotics, production lines, and heavy machinery.

-

Consumer Electronics: Smartphones, home appliances, and gaming devices.

-

Medical Equipment: Imaging systems, monitoring devices, and life-support systems.

By providing structured connectivity, wire harnesses ensure that complex systems operate safely, efficiently, and reliably.

How to Choose the Right Wire Harness for Your Needs

Selecting the right wire harness is critical for performance, safety, and durability. Different environments and applications demand different specifications, so understanding the technical details is essential.

Fanyway Wire Harness Specifications

| Parameter | Specification |

|---|---|

| Material | PVC, Teflon, Silicone, or Custom |

| Conductor Type | Copper, Tinned Copper, or Aluminum |

| Voltage Rating | Up to 600V |

| Temperature Range | -40°C to +125°C |

| Wire Gauge Options | 18 AWG to 28 AWG |

| Connector Options | JST, Molex, TE, Customized |

| Protection | Heat shrink, braided sleeves, tubing |

| Certifications | UL, ISO9001, RoHS, CE |

By tailoring the wire harness design to the environment, electrical load, and integration requirements, Fanyway ensures optimal performance and long-lasting reliability.

Why High-Quality Wire Harnesses Improve System Performance

Choosing a high-quality wire harness is not just about connecting wires; it’s about enhancing system efficiency, safety, and durability. Inferior harnesses can lead to frequent breakdowns, increased maintenance costs, and even safety hazards.

Benefits of Using High-Quality Wire Harnesses

-

Optimized Electrical Performance

Reduced resistance and stable power delivery improve device efficiency. -

Long-Term Durability

High-quality materials resist wear, vibration, and environmental stress. -

Reduced Installation Time

Pre-organized harnesses streamline assembly and minimize human error. -

Improved Safety Standards

Reliable insulation and fire-retardant materials lower the risk of electrical accidents. -

Cost Savings Over Time

Fewer failures mean lower maintenance and replacement costs.

Customization for Industry-Specific Needs

Fanyway offers customized wire harness solutions designed for diverse sectors:

-

For automotive systems, we provide heat-resistant harnesses built to endure high engine temperatures.

-

For industrial automation, we design flexible, vibration-resistant harnesses for heavy machinery.

-

For consumer electronics, we focus on compact designs suitable for tight spaces.

With a strong focus on innovation, precision, and safety, Fanyway ensures every harness delivers consistent performance under real-world conditions.

Frequently Asked Questions About Wire Harnesses

Q1. What is the difference between a wire harness and a cable assembly?

A wire harness organizes multiple individual wires into a single structure, typically for short-distance applications within a device or machine. A cable assembly, on the other hand, is designed for long-distance power or signal transmission and usually includes thicker insulation and shielding.

Q2. How long does a wire harness typically last?

The lifespan of a wire harness depends on material quality, environmental conditions, and usage. High-quality harnesses like those manufactured by Fanyway can last 10 to 20 years or more, especially when designed with heat-resistant insulation and reinforced connectors.

Fanyway — Your Trusted Partner for Wire Harness Solutions

In today’s fast-paced technological landscape, wire harnesses play an essential role in ensuring seamless electrical connectivity, safety, and performance. From automotive and aerospace systems to consumer electronics and industrial automation, their applications are vast and critical.

At Fanyway, we specialize in delivering custom-designed, high-performance wire harness solutions that meet international safety and quality standards. Whether you need a standard harness or a fully tailored design, our team provides engineering expertise, premium materials, and strict quality control.

Ready to elevate your electrical systems with reliable wire harness solutions? Contact us today to discuss your project requirements and discover how Fanyway can power your success.