Why Choose Rigid Flex PCB for Advanced Electronic Applications?

2025-09-11

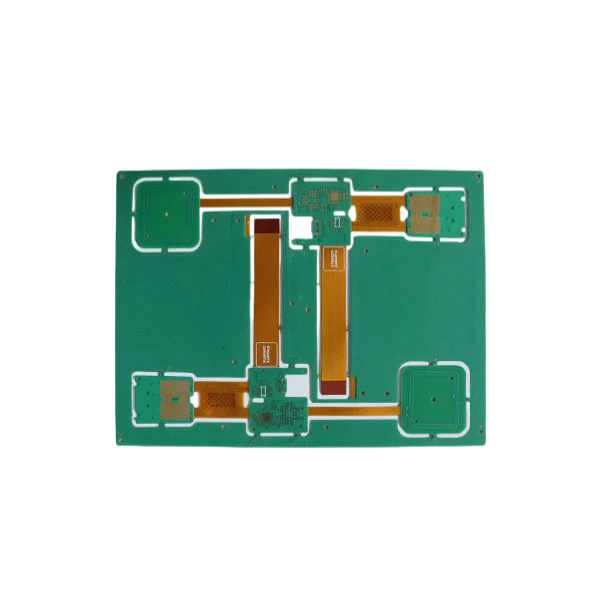

In today’s electronics industry, where devices are becoming increasingly compact, lightweight, and multifunctional, the demand for innovative printed circuit board (PCB) solutions has risen sharply. Among the most transformative technologies is the Rigid Flex PCB. This hybrid solution combines the durability and stability of rigid PCBs with the adaptability and lightweight characteristics of flexible circuits, providing engineers with new possibilities for designing high-performance products.

Rigid Flex PCBs are constructed by integrating multiple layers of flexible circuits between rigid circuit board sections. These layers are internally connected, forming a unified, cohesive structure. This combination not only reduces the need for connectors and wiring but also minimizes overall space usage, weight, and assembly complexity.

The importance of Rigid Flex PCBs becomes even clearer when considering modern application fields such as medical devices, aerospace, automotive electronics, industrial control, and consumer electronics. Traditional PCBs often fall short in these environments due to size, weight, or vibration resistance limitations. In contrast, Rigid Flex PCBs excel because they deliver reliability and design flexibility without sacrificing structural integrity.

The evolution of this technology can be traced back to the increasing need for miniaturization and enhanced performance. From implantable medical devices to rugged military equipment, industries demand PCBs that can withstand stress, provide reliable signal transmission, and enable complex three-dimensional designs. Rigid Flex PCBs, therefore, have become indispensable.

Key Advantages of Rigid Flex PCB:

-

Space Saving: Eliminates bulky connectors and cables, enabling smaller product footprints.

-

Durability: Withstands harsh environments, vibration, and bending without signal degradation.

-

Signal Integrity: Reduces interference and improves high-frequency performance due to shorter interconnections.

-

Design Freedom: Allows 3D design integration, creating more ergonomic and compact devices.

-

Reliability: Fewer solder joints and connectors reduce the risk of failures over product lifespan.

In summary, the significance of Rigid Flex PCB lies in its ability to bridge the gap between design creativity and real-world manufacturing constraints, supporting industries where compactness and robustness are critical.

The working principle of a Rigid Flex PCB revolves around its layered construction. Rigid sections provide stability for mounting components, while flexible sections interconnect these rigid islands, enabling bending and folding during assembly or in end-use applications. This structural integration results in improved electrical performance and reduced mechanical stress.

To understand Rigid Flex PCBs more thoroughly, reviewing their technical parameters is crucial. Below is a professional summary of the key specifications commonly offered:

| Parameter | Specification Range |

|---|---|

| Layer Count | 2 to 20+ layers (depending on design complexity) |

| Material | FR4 + Polyimide (flexible base material) |

| Copper Thickness | 0.5 oz – 3 oz (customizable) |

| Flexible Layer Thickness | 0.05mm – 0.20mm |

| Rigid Layer Thickness | 0.2mm – 3.2mm |

| Minimum Trace Width/Spacing | 3/3 mil (advanced processes available) |

| Hole Size (Plated) | 0.1mm – 6.0mm |

| Impedance Control Tolerance | ±10% or better |

| Surface Finish | ENIG, OSP, Immersion Tin, HASL, Hard Gold |

| Bend Radius | As low as 10x material thickness (design-driven) |

| Operating Temperature | -40°C to +150°C (application-specific) |

| Certifications | IPC-6013, RoHS, UL, ISO9001, Automotive Grade |

These parameters highlight the customization potential and versatility of Rigid Flex PCBs. For example, the ability to design with multiple flexible layers allows engineers to create foldable circuits that reduce assembly steps and maintain strong signal paths. Similarly, the use of polyimide as a flexible base material ensures excellent thermal stability and mechanical resilience.

How It Works in Practice:

-

Electrical Pathway Integration: The flexible portions act as dynamic wiring routes, connecting rigid sections seamlessly.

-

Mechanical Adaptability: Flexible arms absorb mechanical stress, preventing component damage.

-

High Reliability Interconnects: Internal connections reduce the need for fragile connectors.

-

Compact Assembly: Enables three-dimensional folding, reducing product footprint.

For instance, in a wearable medical device, Rigid Flex PCB allows sensors and microcontrollers to be distributed across multiple rigid boards, connected through flexible layers that adapt to the body’s curvature. This flexibility improves comfort while maintaining data accuracy.

When evaluating PCB technologies, industries must balance cost, performance, and reliability. While rigid PCBs and flexible PCBs each have their benefits, Rigid Flex PCBs offer an unmatched combination of these qualities.

Key Reasons Industries Choose Rigid Flex PCBs:

-

Miniaturization Demands: In consumer electronics like smartphones, smartwatches, and fitness trackers, smaller yet more powerful PCBs are essential. Rigid Flex PCBs enable designers to pack more features into smaller spaces without compromising functionality.

-

Harsh Operating Environments: Automotive and aerospace applications require PCBs to withstand vibration, shock, and temperature fluctuations. The structural resilience of Rigid Flex PCB ensures dependable performance.

-

Cost Efficiency in the Long Term: Although the initial manufacturing cost can be higher compared to traditional PCBs, the overall lifecycle cost is lower. Reduced assembly steps, fewer connectors, and improved reliability translate into lower maintenance and replacement expenses.

-

Enhanced Aesthetic and Ergonomics: In modern device design, sleekness is critical. By integrating circuitry into 3D assemblies, manufacturers can produce thinner, lighter, and more ergonomic products.

-

High-Frequency Capability: With fewer interconnections and short signal paths, Rigid Flex PCBs excel in high-frequency, high-speed communication applications.

Consider the example of defense electronics. Conventional rigid PCBs would require numerous connectors and cabling to connect different system modules, increasing weight and potential failure points. With Rigid Flex PCB technology, the same system becomes lighter, more compact, and far more reliable under field conditions.

From medical implants to satellites, Rigid Flex PCBs answer the crucial "why" industries are adopting this technology: because reliability, miniaturization, and long-term performance are no longer optional—they are mandatory.

Even though the advantages of Rigid Flex PCBs are significant, engineers and procurement specialists often have recurring questions before adoption. Below are two of the most common FAQs with clear, professional answers.

Q1: What is the typical lifespan of a Rigid Flex PCB compared to standard PCBs?

A Rigid Flex PCB generally has a longer lifespan due to fewer solder joints, reduced connectors, and superior mechanical resilience. Traditional PCBs are more vulnerable to cracking, connector failures, or delamination in high-stress environments. With Rigid Flex PCB technology, the integrated design reduces these risks, often extending the functional lifespan by 2–3 times compared to standard rigid boards. The actual lifespan depends on usage conditions, but in demanding environments, Rigid Flex PCBs consistently outperform alternatives.

Q2: Are Rigid Flex PCBs more expensive, and if so, why are they worth the cost?

Yes, the upfront manufacturing cost of a Rigid Flex PCB is higher due to specialized materials and processes. However, this cost is offset by reduced assembly labor, fewer connectors, minimized wiring, and lower maintenance needs. Over a product’s lifetime, Rigid Flex PCBs save significant costs because they decrease failure rates, extend device durability, and streamline production. For industries where reliability and compact design are critical, the long-term value far outweighs the initial investment.

Rigid Flex PCBs represent a leap forward in electronic design, merging the advantages of rigid stability and flexible adaptability into a single, high-performance solution. Their role in enabling miniaturization, durability, and cost efficiency makes them indispensable for industries ranging from aerospace and defense to healthcare and consumer electronics.

Fanway, with years of expertise in PCB manufacturing, offers advanced Rigid Flex PCB solutions tailored to industry-specific requirements. By combining precision engineering, certified materials, and rigorous quality standards, Fanway ensures every board meets the expectations of demanding applications worldwide.

If your project requires reliable, compact, and high-performance PCB technology, contact us today to learn how Fanway can deliver Rigid Flex PCBs that empower your innovation.