Why Are Precision Injection Molded Parts Gaining Traction?

2025-10-13

Precision injection molded parts refer to high-tolerance, intricately designed plastic (or polymer composite) components manufactured via injection molding under strictly controlled process parameters. Compared to conventional injection molding, this technique focuses on ultra-fine dimensional control, repeatability, minimal defects, and suitability for industries such as medical devices, aerospace, optics, and electronics.

Defining Precision Injection Molded Parts & Key Specifications

What distinguishes a “precision” injection molded part?

-

Tight tolerances: Dimensional accuracy often in the range of ±0.01 mm to ±0.001 mm (in some ultra-precision applications)

-

Complex geometries and small features: Micro-features, thin walls, fine ribs, small holes, insert molding, multi-material sections

-

Consistent repeatability: Very low variation from cycle to cycle

-

High surface quality and low defects: Minimal warpage, sink marks, flash, etc.

-

Material stability: Use of high-performance polymers (e.g. PEEK, PPS, high-grade reinforced resins) to maintain mechanical, thermal, and chemical properties under close tolerances

Example Technical Parameters (typical range)

| Parameter | Typical Value / Range |

|---|---|

| Tolerance | ±0.01 mm to ±0.001 mm (depending on geometry) |

| Injection pressure | 216 – 243 MPa (or higher for ultra-precision) |

| Temperature control | Mold & melt control within ±1 ℃ (PID or closed loop) |

| Clamping accuracy | Parallelism control within 0.06-0.08 mm |

| Speed / Multi-stage control | Multi-segment injection & holding phases |

| Cycle time (for small parts) | Often very short (high throughput) with careful cooling design |

| Material types | High-grade thermoplastics (e.g. PEEK, PPS, ABS, polycarbonate, reinforced resins) |

These parameters and process controls collectively allow high precision, minimal defect rates, and stable repeatability for advanced and demanding applications.

Why Precision Injection Molded Parts Are Increasingly Valued

(i) Superior Quality & Performance

Precision injection molded components deliver exceptional mechanical integrity, dimensional fidelity, and aesthetic quality. Because defects like warpage, flash, or sink are minimized, downstream assembly, sealing, and performance reliability are greatly improved.

(ii) Efficiency & Reduced Waste

Tighter tolerances reduce the need for post-processing, trimming, or rework. Material utilization is improved, and scrap rates drop. Automated monitoring and optimized cycle control further enhance yield.

(iii) Scalability & Repeatability

Even though the initial mold and machine setup may be more demanding, once calibrated, the process can deliver thousands or millions of parts with near-identical performance, which is critical in high-volume sectors (automotive, consumer electronics, medical implants).

(iv) Industry & Market Drivers

-

Reshoring and supply chain resilience: Companies are bringing manufacturing closer to end markets to reduce lead times, mitigate shipping/logistics risks, and avoid tariff impacts.

-

Demand for miniaturization and precision: In electronics, medical, automotive, customers require ever smaller, more precise components.

-

Sustainability & material innovation: Use of recycled, bio-derived materials or high-performance resins under precise control is growing.

-

Smart manufacturing / Industry 4.0: Real-time sensing, closed-loop control, predictive maintenance, AI optimization enhance precision and reduce variation

-

Market growth: The global precision injection molding market is projected to grow steadily with demand in medical, electronics, aerospace, and packaging sectors.

Thus, precision injection molded parts are increasingly seen not just as luxury, but as strategic enablers for high-end, high-reliability products.

Engineering, Control, & Emerging Techniques for Precision Molding

(A) Process & Control Techniques

-

Multi-stage injection & segmented control

Injection speed, pressure, and holding phases are carefully segmented to match complex geometries. This reduces defects (e.g. weld lines, internal stress) and maintains strong consistency. -

Closed-loop sensors & real-time feedback

Pressure sensors in nozzle, hot runner, and mold cavities feed data to control systems, enabling instant adjustment to maintain ideal pressure profiles.

Advanced control algorithms, such as feedback linearization models, help track target pressure trajectories dynamically. -

Temperature control & mold cooling design

Maintaining melt and mold temperatures precisely (±1 ℃) is fundamental. Mold cooling channels (often conformal cooling) are designed to remove heat uniformly and rapidly.

Conformal cooling channels closely follow the geometry of the part to reduce cycle time and warpage. -

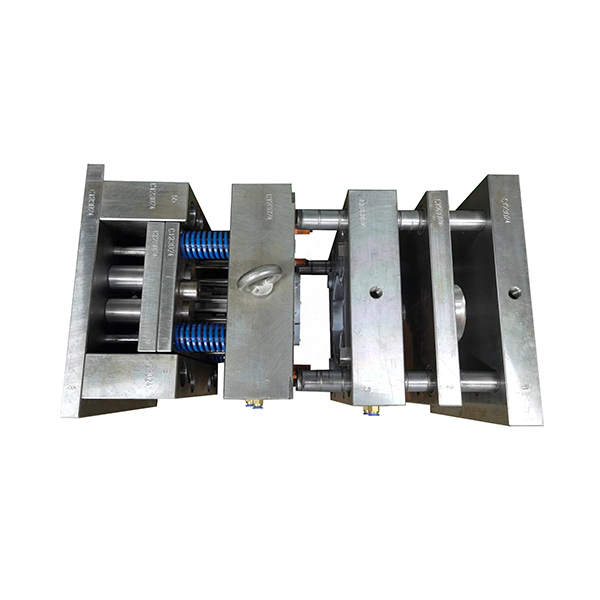

High-rigidity mold & clamping systems

To prevent deflection or misalignment under high pressure, molds and clamping platens are designed with high stiffness. Clamping repeatability and platen parallelism are strictly controlled. -

Hot runner systems & runnerless designs

Hot runner systems allow continuous molten plastic flow without freezing in runners, reducing waste and enabling shorter cycle times. -

Design for manufacturability, simulation, and mold validation

CAD/CAE simulation (flow, cooling, warpage) is used prior to mold construction. Tools like VR validation can help detect design interference or disassembly issues before mold fabrication.

Iterative mold validation ensures the mold and part design are matched for precision requirements.

(B) Emerging and Advanced Techniques

-

Micro injection molding: For extremely small, high-precision parts (medical stents, micro connectors). Requires ultra-precise control of temperature and pressure.

-

Multi-material / overmolding: Combining rigid and flexible polymers or incorporating inserts in one mold cycle.

-

Additive-assisted mold inserts: 3D-printed conformal cooling inserts or inserts to accelerate mold development.

-

On-demand & just-in-time precision injection molding: Shifting toward low-volume, rapid-turn production aligned with demand.

-

Smart factory integration: IoT, AI, real-time analytics enable zero-defect strategy, predictive maintenance, adaptive control.

Common Questions (FAQ Mode)

Q: What materials are suitable for precision injection molding?

A: High-performance thermoplastics (such as PEEK, PPS, polycarbonate, ABS, reinforced polymers) and composite blends are commonly used, because they combine dimensional stability, mechanical performance, and processability. Additionally, glass- or carbon-fiber reinforced grades help increase strength and stiffness while maintaining precision.

Q: How is warpage and shrinkage controlled in precision parts?

A: Warpage and shrinkage are minimized through balanced mold cooling (often conformal cooling), precise temperature control, optimized gate and runner design, and segmented pressure holding schemes. Simulation and CAE optimization help predict and mitigate distortions before mold fabrication.

Q: Is the cost significantly higher compared to standard injection molding?

A: The upfront cost (mold design, sensor integration, machine setup) is higher. However, the savings from reduced scrap, lower rework, tighter yields, and better performance often justify the investment in medium-to-high volume or critical applications.

Q: Can precision injection molded parts scale from prototype to mass production?

A: Yes. One of the strengths of precision injection molding is its scalability: once the process is dialed in, the same mold and controls can be used across volumes with consistent performance.

The Future Outlook & Strategic Implications

-

Trend toward reshoring & nearshoring: Many companies are relocating precision molding closer to demand centers to reduce lead times, logistics risk, and tariff exposure.

-

Demand for micro, miniaturized, and smart components will fuel growth in precision molding.

-

Greater adoption of AI and automation will push defect rates even lower while boosting throughput.

-

Sustainable and bio-derived materials under tight process control will become more common.

-

Digital twin and VR/AR validation of molds and processes will reduce development cycles and errors.

Conclusion & Brand Mention / Call to Action

Precision injection molded parts represent a fusion of advanced engineering, rigorous process control, and material science to deliver components with exceptional precision, performance, and consistency. Through careful design, closed-loop control, and emerging techniques like conformal cooling and AI optimization, manufacturers can produce parts that meet the most demanding requirements with high yield and minimal defects.

As the market continues to demand miniaturization, faster turnaround, and sustainability, suppliers who master precision molding will hold a competitive advantage. Ai Cheng stands at the forefront of this domain, offering precision injection molded components tailored to the aerospace, medical, electronics, and automotive sectors. For inquiries or to collaborate on your next precision molding project, contact us.