Why Are Copper Braided Wires the Choice for Electrical Applications?

2025-09-26

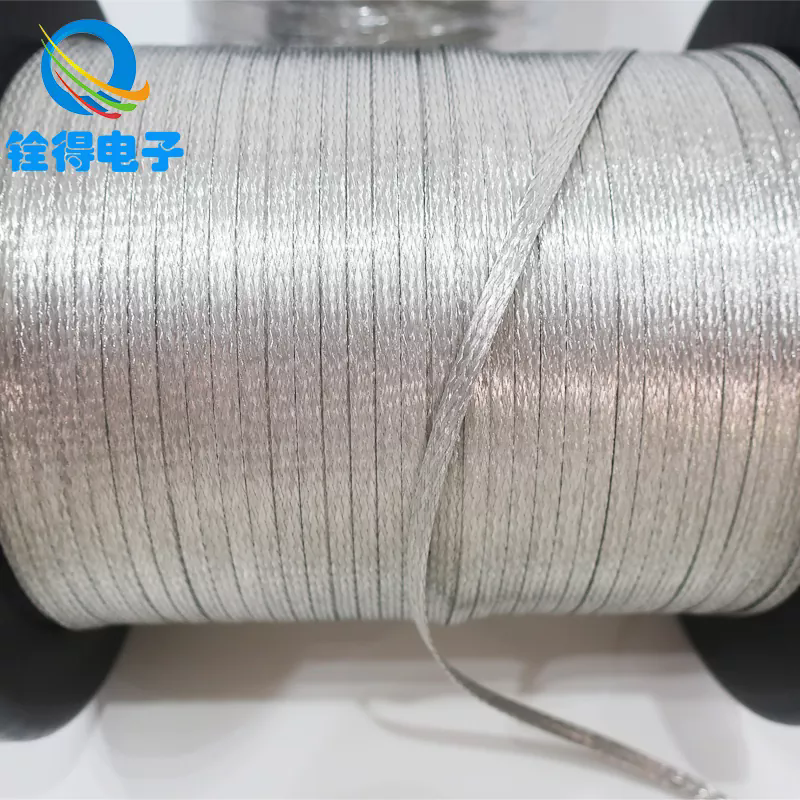

Copper braided wires are highly flexible electrical conductors manufactured from multiple strands of fine copper filaments that are woven together into a tubular or flat braid form. Unlike single solid wires, braided wires offer mechanical flexibility, excellent conductivity, and superior durability, making them indispensable in industries where electrical performance must coexist with physical resilience.

At their core, copper braided wires solve a fundamental engineering challenge: how to ensure consistent current transmission while enduring mechanical stress, bending, vibration, or movement. From automotive systems to aerospace technologies, these wires form the backbone of reliable grounding, shielding, and power transfer solutions.

Key Benefits of Copper Braided Wires:

-

Flexibility: Able to withstand repeated bending and vibration.

-

Conductivity: Excellent electrical current transfer due to the purity of copper.

-

Durability: Resistant to wear, mechanical stress, and fatigue.

-

Shielding: Effective against electromagnetic interference (EMI).

-

Versatility: Suitable for grounding, power connectors, welding cables, and shielding applications.

The choice of copper over other metals is not arbitrary. Copper possesses a superior balance of conductivity, corrosion resistance, and cost-effectiveness, making it an industry standard for high-performance braided conductors.

How Are Copper Braided Wires Manufactured and Applied?

The manufacturing process of copper braided wires combines precision engineering with advanced weaving technology. Copper strands, often tin-plated for enhanced corrosion resistance, are interwoven into braids that can be either flat or tubular depending on the intended application.

Main Manufacturing Characteristics:

-

Material: High-conductivity oxygen-free copper or tinned copper.

-

Construction: Woven braids of fine wires ranging from 0.05mm to 0.2mm in diameter.

-

Form: Flat braids for grounding straps, tubular braids for shielding and cable sleeves.

-

Plating Options: Bare copper, tin-plated copper, silver-plated copper, nickel-plated copper.

-

Sizes Available: Cross-sectional areas from 1mm² to over 100mm².

-

Operating Temperatures: -55°C to +200°C depending on plating and insulation.

-

Resistance Values: Extremely low resistance per meter due to copper’s conductivity.

Example Specification Table

| Parameter | Specification Range |

|---|---|

| Material | Bare Copper / Tinned / Silvered |

| Wire Strand Diameter | 0.05 – 0.20 mm |

| Cross Section Area | 1 mm² – 120 mm² |

| Operating Temperature | -55°C to +200°C |

| Electrical Conductivity | >97% IACS |

| Plating Options | Tin, Nickel, Silver |

Core Applications:

-

Electrical Grounding: Provides low-resistance grounding in power systems and vehicles.

-

Shielding: Used in cable shielding to protect signals from EMI.

-

Flexible Connectors: Applied in busbars, switchgear, and transformers for current transfer.

-

Automotive Industry: Reduces vibration-induced failures in car wiring harnesses.

-

Aerospace & Railways: Withstands mechanical movement and environmental stress.

-

Welding Equipment: Handles high current loads flexibly and safely.

The adaptability of copper braided wires allows engineers to incorporate them into systems where both flexibility and conductivity are non-negotiable.

Why Should Industries Choose Copper Braided Wires Over Alternatives?

Choosing copper braided wires over solid conductors or aluminum-based solutions is a matter of performance, safety, and lifecycle cost.

Main Reasons to Choose Copper Braided Wires:

-

Superior Conductivity:

Copper braided wires maintain electrical efficiency due to low resistivity, minimizing power losses in transmission. -

Mechanical Flexibility:

Their woven structure absorbs stress and vibration, reducing the risk of wire breakage and prolonging operational life. -

Corrosion Resistance:

Tin or nickel plating enhances resistance to oxidation, making them suitable for humid or corrosive environments. -

Heat Dissipation:

The braiding structure allows efficient airflow and heat dissipation, critical for high-current applications. -

Safety and Reliability:

With stable current-carrying capacity, they ensure reliable performance in critical applications like aerospace, medical equipment, and energy distribution. -

Lifecycle Cost Efficiency:

Although initial costs may be higher than alternatives like aluminum, the reduced maintenance and longer service life make copper braided wires a cost-effective choice. -

Environmental Compatibility:

Copper is fully recyclable, supporting sustainability initiatives in modern industries.

When industries prioritize performance under demanding conditions, copper braided wires emerge as the logical solution. They combine the strength of traditional conductors with adaptability suited for modern engineering challenges.

How to Select the Right Copper Braided Wire for Your Needs?

Selecting the correct type of copper braided wire depends on the specific operational requirements, including current load, flexibility needs, environmental conditions, and mechanical stress.

Key Considerations in Selection:

-

Current Capacity: Ensure the cross-sectional area supports the intended electrical load.

-

Flexibility Requirements: Choose finer strand diameters for higher flexibility.

-

Environmental Conditions: Tin or nickel plating is recommended for humid, corrosive, or high-temperature applications.

-

Shape and Form: Flat braids are ideal for grounding straps; tubular braids excel in cable shielding.

-

Durability: Consider the mechanical environment—vibration, movement, or repeated bending.

-

Compliance: Ensure wires meet international safety standards such as RoHS, UL, and IEC.

By carefully balancing these parameters, industries can optimize both performance and cost-efficiency.

FAQs About Copper Braided Wires

Q1: What makes copper braided wires better than solid copper conductors?

A1: They provide the same electrical conductivity while offering superior flexibility and durability under vibration and bending stress.

Q2: Can copper braided wires be used outdoors?

A2: Yes, especially when tin-plated or nickel-plated, as these coatings enhance corrosion resistance for outdoor or marine environments.

Q3: How do copper braided wires improve safety in electrical systems?

A3: Their low resistance and excellent flexibility reduce overheating risks, ensure stable grounding, and minimize the chance of mechanical failure.

Copper braided wires are more than just an electrical component—they are a vital foundation for modern engineering systems that demand both electrical reliability and mechanical resilience. Their proven performance in grounding, shielding, and current transfer ensures they remain indispensable across automotive, aerospace, energy, and industrial sectors.

At Quande, we are dedicated to delivering precision-engineered copper braided wires that meet international standards while offering customization for unique project requirements. Our solutions are designed to help clients achieve long-term reliability and efficiency in their applications. For detailed specifications or tailored orders, please contact us today and discover how our copper braided wires can power your success.