Why Are Copper Braided Wires the Backbone of Modern Electrical Engineering?

2025-10-23

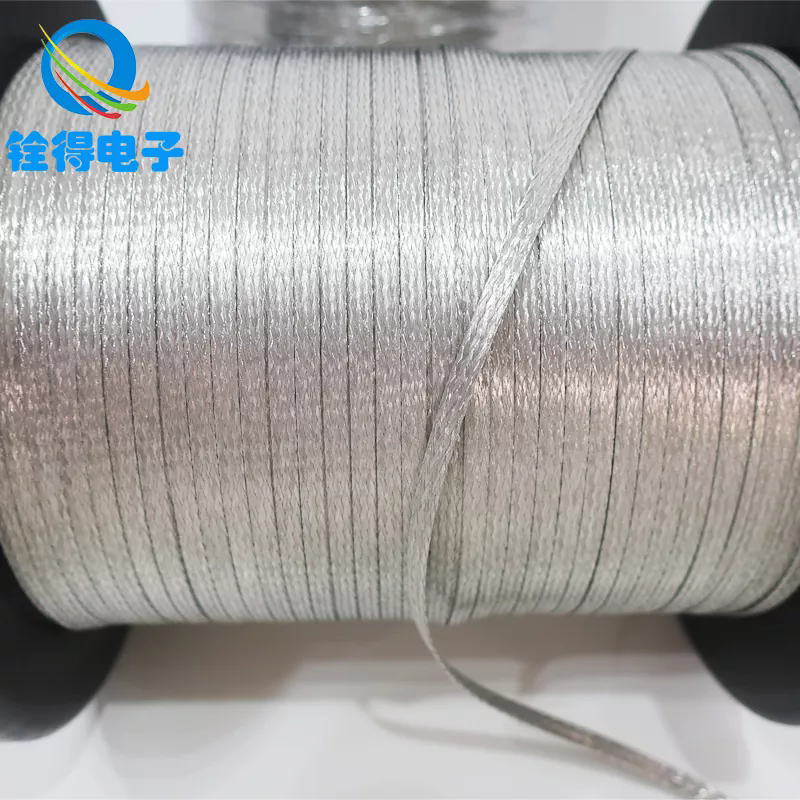

In the world of electrical and mechanical engineering, Copper Braided Wires have become a critical component that ensures flexibility, durability, and superior conductivity in various applications. These woven copper strands are widely used in grounding systems, flexible connections, and electromagnetic shielding across industries like automotive, aerospace, telecommunications, and power distribution.

What Are Copper Braided Wires?

Copper Braided Wires are bundles of fine copper strands interwoven in a tubular, flat, or round form to create a flexible conductor. The braiding process not only provides excellent mechanical strength but also allows the wire to bend and flex without breaking, making it suitable for applications requiring repeated motion or vibration resistance.

They are generally manufactured using tinned, bare, or silver-plated copper, with each variation designed for different performance environments—ranging from standard grounding uses to high-temperature or corrosive conditions.

Key Product Specifications and Parameters

| Parameter | Specification |

|---|---|

| Conductor Material | Bare Copper / Tinned Copper / Silver-Plated Copper |

| Structure Type | Flat Braid / Round Braid / Tubular Braid |

| Wire Gauge Range | AWG 4 – AWG 36 |

| Number of Strands | 48 – 192 per braid |

| Cross-sectional Area | 1 mm² – 400 mm² |

| Tensile Strength | 200 – 250 N/mm² |

| Operating Temperature | -55°C to +200°C |

| Conductivity | 97% – 100% IACS (International Annealed Copper Standard) |

| Shielding Efficiency | Up to 90 dB (at 1 MHz) |

| Applications | Grounding, Busbars, EMI/RFI Shielding, Power Distribution, Battery Systems |

These parameters highlight the adaptability and strength of Copper Braided Wires, making them the preferred choice where both conductivity and mechanical resilience are required.

Why Are Copper Braided Wires So Important in Modern Industry?

The importance of Copper Braided Wires lies in their unique balance between flexibility and conductivity—two properties rarely found together in solid conductors. Industries worldwide depend on these wires for several key reasons:

-

Superior Electrical Conductivity:

Copper remains one of the most conductive metals known, ensuring minimal energy loss during current transmission. This efficiency is vital in power generation and distribution systems. -

Flexibility and Fatigue Resistance:

The braided structure enables the wire to endure continuous bending, vibration, and movement, especially in machinery, vehicles, and robotics where rigid cables would fail. -

Excellent Shielding Against Electromagnetic Interference (EMI):

Copper braids serve as an effective EMI/RFI shield, preventing signal disruption in sensitive electronic circuits—essential for aerospace, data centers, and telecommunications equipment. -

Thermal and Corrosion Resistance:

Tinned or silver-plated versions protect against oxidation and extreme environmental conditions, making them suitable for marine or outdoor installations. -

Mechanical Durability:

The interwoven strands act as a cushion against mechanical stress, reducing the risk of breakage, especially in high-vibration environments. -

Ease of Installation and Integration:

Their flexibility simplifies installation, especially in confined spaces or complex routing paths.

How Do Copper Braided Wires Work in Real Applications?

Understanding how these wires function requires examining their role in electrical circuits and mechanical systems.

-

In Electrical Grounding Systems:

Copper Braided Wires create a low-resistance path to ground, protecting equipment and personnel from electrical faults. Their flexibility allows easy bonding between movable components, such as doors, panels, and rotating machinery. -

In Power Distribution and Busbars:

They connect transformers, generators, and switchgear components. The flexibility of the braid prevents stress at connection points due to vibration or thermal expansion. -

In Shielded Cables:

Braided wires serve as electromagnetic shields, encasing the signal conductor and preventing interference from external electromagnetic fields. This is vital in communication cables, sensor lines, and control circuits. -

In Automotive and Aerospace Applications:

Copper Braided Wires are used in grounding systems, battery connections, and static discharge paths. Their low resistance and vibration tolerance make them indispensable for safety and reliability. -

In Renewable Energy Systems:

Solar panels, wind turbines, and battery banks rely on braided conductors to ensure efficient current transfer under fluctuating temperatures and environmental stress.

Why Copper Over Alternatives?

While aluminum or composite conductors have their place, copper remains the standard for braided wires due to its combination of:

-

Higher electrical conductivity

-

Better mechanical strength

-

Superior corrosion resistance

-

Longer operational life

This combination ensures consistent performance even under extreme conditions where alternatives may degrade faster.

What Are the Future Trends of Copper Braided Wires?

As global industries continue to move toward electrification and sustainable energy solutions, the role of Copper Braided Wires is expanding rapidly. Future trends point toward smart manufacturing, eco-friendly materials, and enhanced performance coatings.

-

Integration in Electric Vehicles (EVs):

With the surge in EV production, Copper Braided Wires are increasingly used for battery grounding, inverter connections, and EMI shielding in onboard electronics. -

Growth in Renewable Energy Infrastructure:

Solar farms, wind turbines, and battery energy storage systems rely on flexible copper connections to withstand outdoor conditions and thermal cycling. -

Advancements in Plating and Coating:

Manufacturers are exploring nano-coatings and hybrid plating technologies that enhance oxidation resistance and mechanical endurance without increasing weight. -

Miniaturization and Lightweight Designs:

The trend toward smaller, more efficient systems demands ultra-fine copper braids that maintain conductivity while reducing size and weight. -

Increased Automation in Production:

AI-assisted braiding machinery and robotic welding ensure precision and uniformity, leading to improved consistency and cost efficiency. -

Sustainability and Recycling:

Copper is 100% recyclable without loss of performance. This aligns perfectly with global sustainability goals and circular economy models.

In essence, the future of Copper Braided Wires lies in combining traditional performance strengths with innovative materials and manufacturing technologies, supporting the next generation of clean and connected industries.

Frequently Asked Questions (FAQ)

Q1: What is the difference between tinned copper braid and bare copper braid?

A1: The main difference lies in corrosion resistance and application environment. Bare copper braid offers maximum conductivity and is ideal for indoor or controlled environments. Tinned copper braid, coated with a thin layer of tin, provides enhanced oxidation and corrosion resistance, making it better suited for marine, automotive, or outdoor installations.

Q2: Can Copper Braided Wires handle high current loads safely?

A2: Yes. Copper Braided Wires can safely handle high current loads due to their excellent conductivity and surface area distribution. The braided design increases flexibility while maintaining electrical efficiency, allowing them to dissipate heat effectively and prevent hotspots, which ensures stability under heavy electrical loads.

The Strength Behind Every Connection — Quande’s Copper Braided Wires

Copper Braided Wires have evolved from simple conductors to vital components in modern electrical systems. Their unmatched balance of flexibility, conductivity, and durability makes them indispensable across industries—from automotive and aerospace to renewable energy and telecommunications.

Quande, a trusted manufacturer in high-performance electrical components, continues to innovate in the field of copper braiding technology. Through precise engineering, advanced production techniques, and strict quality control, Quande delivers Copper Braided Wires that meet the highest international standards.

For reliable grounding, stable power connections, and superior shielding performance, Quande Copper Braided Wires are the choice for engineers who demand excellence and long-term reliability.

Contact us today to discover how Quande can support your electrical engineering projects with advanced Copper Braided Wire solutions.