Why Are Automotive PCBs Transforming Vehicle Electronics?

2025-11-20

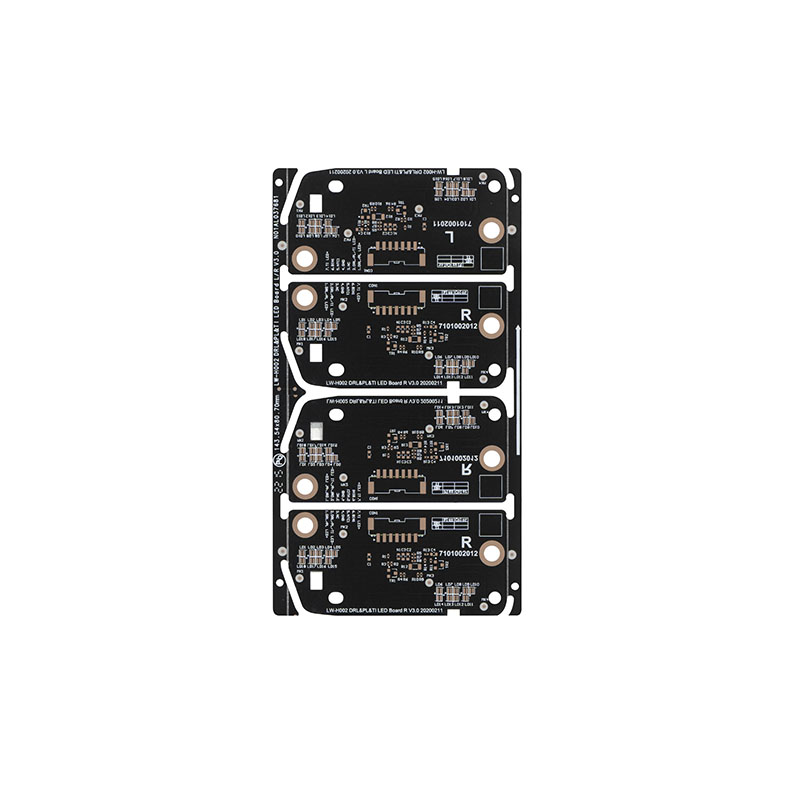

Automotive Printed Circuit Boards (PCBs) serve as the electronic backbone of today’s vehicles, enabling crucial functions across safety systems, power management, infotainment, engine control, and advanced driver-assistance technologies. As vehicles evolve toward higher intelligence, improved energy efficiency, and enhanced connectivity, Automotive PCBs have become indispensable components that determine reliability, performance stability, and long-term durability.

Key Product Parameters of Automotive PCBs

High-performance Automotive PCBs are engineered to endure harsh operating environments such as extreme heat, humidity, vibration, and corrosive chemicals. Below is a concise technical parameter table highlighting the core attributes:

| Parameter | Specification |

|---|---|

| Base Material | High-temperature FR4, Polyimide, Aluminum Substrate, Copper Substrate |

| Thermal Conductivity | 1.0–3.0 W/m·K (metal-based can reach 5–10 W/m·K) |

| Layer Count | 2–16 layers or custom multilayer structure |

| Copper Thickness | 1–4 oz depending on current load |

| Operating Temperature | –40°C to +150°C (automotive-grade) |

| Surface Finish | ENIG, HASL-LF, OSP |

| Solder Mask | High-CTE, high-humidity-resistant materials |

| Vibration Resistance | Automotive-grade anti-shock design |

| Compliance Standards | IATF16949, IPC-6012DA, RoHS |

These parameters ensure the PCB can support critical automotive systems such as engine control units (ECUs), LED lighting modules, battery management systems (BMS), radar, camera modules, and infotainment displays.

Why Are Automotive PCBs Critical to Vehicle Reliability, Performance, and Safety?

Automotive PCBs support multiple core technologies that define modern vehicles. Understanding their value helps clarify why more manufacturers prioritize the selection of automotive-grade board materials, surface finishes, and multilayer design structures.

Why Do Automotive PCBs Improve Vehicle Safety?

Safety systems rely heavily on stable electronic communication. Automotive PCBs ensure uninterrupted electrical signals for:

-

Anti-lock braking systems (ABS)

-

Airbag deployment systems

-

Tire pressure monitoring systems (TPMS)

-

Electronic stability control (ESC)

-

Radar and camera sensors for ADAS

Stable PCB conductivity and heat resistance prevent signal delays or failures, directly influencing passenger and driver protection.

Why Do Automotive PCBs Enhance Vehicle Energy Efficiency?

Automotive PCBs support efficient power distribution across high-voltage and low-voltage systems. They improve:

-

Battery management accuracy in EVs and HEVs

-

Power conversion efficiency in onboard chargers

-

Energy recovery performance in brake-regeneration systems

Thicker copper layers (up to 4 oz) and improved thermal conductivity allow heat to dissipate quickly, preventing component burnout and increasing overall energy efficiency.

Why Are Automotive PCBs Essential for Intelligent Driving?

From autonomous driving to vehicle-to-everything (V2X) communication, PCBs serve as the hardware foundation. They power:

-

Millimeter-wave radar (24GHz/77GHz)

-

LiDAR modules

-

High-resolution cameras

-

AI-based advanced driver assistance systems

These systems require multilayer PCBs with stringent impedance control and low-loss materials to preserve signal integrity.

How Do Automotive PCBs Function Within Key Vehicle Systems?

Automotive PCBs support nearly every electronic system within a vehicle. Understanding how they operate across different subsystems helps clarify their role in overall vehicle performance.

How Do Automotive PCBs Support Powertrain and Engine Control?

Powertrain electronics require PCBs with superior heat resistance and vibration durability. Automotive PCBs manage:

-

Engine ignition timing

-

Fuel injection control

-

Turbocharging and emission systems

-

Transmission shifting logic

With stable signal pathways and rapid processing capability, PCBs enable smoother engine performance and reduced emissions.

How Do Automotive PCBs Improve Comfort and Infotainment Systems?

Automotive PCBs power:

-

Digital dashboards

-

Touchscreen multimedia interfaces

-

Advanced audio systems

-

Interior LED lighting systems

-

Climate control modules

High-speed multilayer PCBs ensure lower interference and faster communication between modules, providing a seamless user experience.

How Do Automotive PCBs Support New Energy Vehicles (EV/HEV)?

Electric vehicles rely on Automotive PCBs more than traditional internal combustion vehicles. Key EV modules include:

-

Battery Management Systems (BMS)

-

Motor control units (MCUs)

-

DC–DC converters

-

Onboard chargers

-

High-voltage safety systems

These require metal-core PCBs, thick-copper PCBs, and multilayer boards capable of withstanding elevated temperatures and long-term electric stress.

How Do Automotive PCBs Maintain Stability in Harsh Conditions?

Harsh automotive environments challenge PCB reliability. To withstand these environments, automotive PCBs use:

-

High-temperature substrates

-

Enhanced shock-absorbing designs

-

Corrosion-resistant finishes

-

High-strength mechanical bonding

These engineering choices prevent cracking, delamination, oxidation, and short circuits even under continuous vehicle vibration.

What Future Trends Will Shape the Development of Automotive PCBs?

The future of Automotive PCB manufacturing is driven by electrification, autonomous driving, and digital connectivity. Understanding these trends helps suppliers and OEMs prepare for the next phase of automotive innovation.

Trend 1: Increasing Demand for High-Density Interconnect (HDI) PCBs

With vehicle electronics becoming more compact yet more powerful, HDI PCBs will play a vital role. Benefits include:

-

Higher wiring density

-

Improved electrical performance

-

Smaller, lighter modules

Expect widespread adoption in ADAS, radar, camera systems, and central processing units.

Trend 2: Rising Adoption of Metal-Core PCBs for Thermal Management

Electric vehicles generate significantly more heat. Metal-core PCBs (MCPCBs) and thick-copper PCBs will continue to expand because they offer:

-

Superior thermal dissipation

-

Improved reliability for LED and power electronics

-

Lower risk of thermal cycling damage

This makes them ideal for EV charging systems, LED headlights, and power conversion modules.

Trend 3: Integration of Flexible and Rigid-Flex PCBs

Adaptive designs are essential as vehicle spaces become more compact. Rigid-flex PCBs support:

-

More complex layouts

-

Vibration resistance

-

Lightweight electronic architectures

Future dashboards, head-up displays, and EV control boards will increasingly rely on these hybrid structures.

Trend 4: Growing Demand for Autonomous Driving Electronics

Autonomous driving increases the need for:

-

Millimeter-wave radar PCBs

-

High-frequency PTFE materials

-

Low-loss signal transmission

-

Multi-sensor fusion modules

Advanced PCB technology ensures reliable sensor accuracy and rapid data communication.

Common Automotive PCB FAQs

Q1: What type of PCB materials are most suitable for automotive applications?

A: High-temperature FR4, Polyimide, aluminum-based substrates, and copper-based boards are commonly used. Their thermal stability, mechanical strength, and ability to resist chemicals and moisture make them suitable for harsh automotive environments. Polyimide and metal-core PCBs are especially favored for power electronics and LED modules.

Q2: How do Automotive PCBs improve vehicle safety systems?

A: Automotive PCBs ensure stable electrical connections and real-time signal transmission in systems such as ABS, airbags, and ADAS sensors. Their vibration resistance, heat tolerance, and shielding capabilities help prevent signal errors or component failure, directly supporting critical safety functions during driving.

Q3: What factors influence the durability of Automotive PCBs?

A: Key durability factors include thermal endurance, material selection, copper thickness, solder mask quality, plating finish, and anti-vibration design. Compliance with IATF16949 and IPC automotive standards also ensures long-term performance reliability in harsh operating conditions.

Conclusion and Contact Information

Automotive PCBs have become the foundation of modern automotive innovation. Their ability to withstand high temperatures, vibration, and complex electronic demands makes them essential for electric vehicles, intelligent driving systems, infotainment modules, and safety equipment. As the automotive industry evolves toward electrification, sensor integration, and autonomous intelligence, the quality standards of Automotive PCBs will continue to rise. Manufacturers who invest in high-performance PCB materials, advanced multilayer structures, and reliable automotive-grade engineering will gain a significant competitive advantage.

Huaerkang remains committed to delivering high-quality Automotive PCBs engineered for durability, performance, and long-term stability. For customized solutions or technical consultation, contact us to discuss specific project requirements and professional support.