What Standards Should Your Industrial Control PCBA Manufacturer Meet

2025-10-16

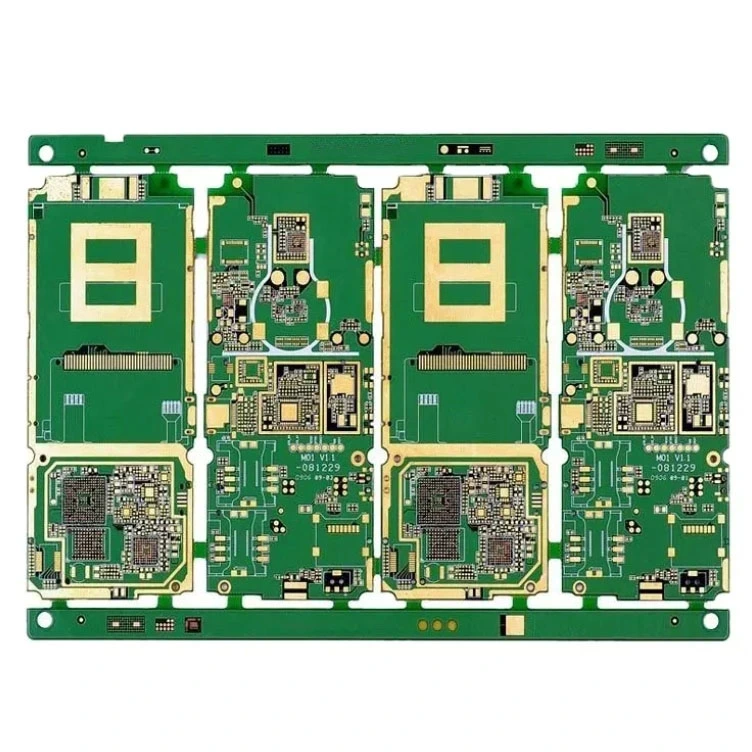

When your production line’s integrity depends on a single circuit board, the manufacturer you choose becomes a strategic partner. The standards they adhere to are not just certificates on a wall; they are your first and most reliable guarantee of performance, safety, and longevity. So, what benchmarks should you demand from your Industrial Control PCBA partner?

Why are Industry Standards Non-Negotiable for Industrial Control PCBA

Compliance ensures that every board is built to withstand the harsh realities of industrial environments. At Greeting, we view these standards as the absolute baseline. They govern everything from material sourcing and traceability to the minutiae of the soldering process. A manufacturer meeting these standards demonstrates a commitment to quality that prevents field failures and costly downtime.

Which Certifications are Critical for Reliable Performance

The most critical certifications form a foundation of trust. Your manufacturer must be ISO 9001 certified for quality management systems and ideally ISO 14001 for environmental management. For the Industrial Control PCBA itself, adherence to IPC-A-610, the worldwide standard for electronic assembly acceptability, is essential. For high-reliability applications, the IPC Class 2 or Class 3 standards define the stricter requirements for dedicated service or critical systems.

| Standard/Certification | Focus Area | Why It Matters for Your Product |

|---|---|---|

| ISO 9001 | Quality Management System | Ensures consistent processes and continuous improvement. |

| IPC-A-610 | Acceptability of Electronic Assemblies | Defines the criteria for workmanship quality you can see. |

| UL 61010-1 | Safety for Electrical Equipment | Certifies the final assembly is safe for operational use. |

| IPC J-STD-001 | Requirements for Soldered Electrical Assemblies | Defines the rigorous requirements for soldering processes. |

How Does Greeting Embed These Standards into Every Board

At Greeting, our process is designed around compliance. It begins with our core capabilities:

-

DFM Analysis: We perform a comprehensive Design for Manufacturability review against IPC guidelines before production.

-

Controlled Documentation: Every Industrial Control PCBA is built from a full traveler package that specifies each standard required.

-

Traceability: We maintain component-level traceability from receipt to final assembly.

Industrial Control PCBA FAQ

What is the difference between IPC Class 2 and Class 3

IPC Class 2 is for dedicated service electronic products where extended life and uninterrupted service are desired, but not critical. IPC Class 3 is for high-reliability or critical systems where performance is mandatory, and no downtime can be tolerated, such as in safety systems or continuous process controls.

How do you ensure EMC/EMI performance in your PCBA

We design for electromagnetic compatibility from the ground up. This includes proper layer stack-up planning, careful component placement for signal integrity, and the use of shielded enclosures. Furthermore, we partner with certified labs to test the final Industrial Control PCBA to relevant EMC standards, ensuring it does not emit harmful interference and is immune to external noise.

What is your process for handling component obsolescence

We maintain a robust component engineering team that proactively monitors the lifecycle of critical parts on your Bill of Materials. When a component is slated for end-of-life, we source and qualify a certified alternative, performing necessary validation testing on the new Industrial Control PCBA build to ensure form, fit, and function are identical or superior.

Choosing a manufacturer is about more than just capability; it's about a shared commitment to quality and reliability. Don't settle for vague promises. Contact us today to discuss your project requirements and receive a full standards compliance report from a team that builds trust into every board.