What Makes Turnkey PCB Assembly the Electronic Manufacturing?

2025-10-14

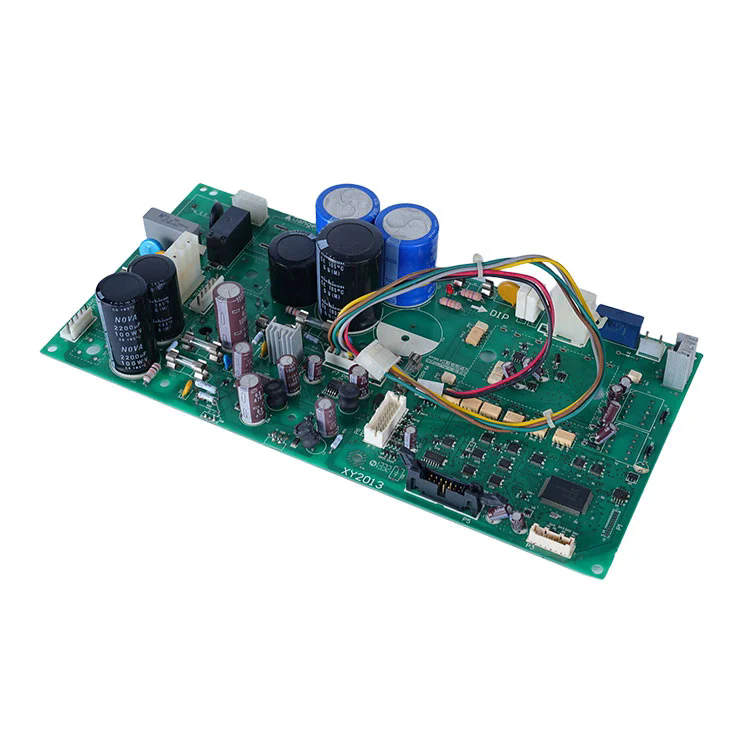

Turnkey PCB Assembly, short for Turnkey Printed Circuit Board Assembly, refers to a streamlined production model in which a single manufacturer manages the entire PCB manufacturing process—from design, component procurement, fabrication, and assembly, to testing and delivery. Unlike traditional PCB assembly, where each stage may be handled by different suppliers, turnkey assembly integrates every step into one cohesive service. This ensures higher efficiency, reduced lead times, and improved product quality for customers in industries ranging from telecommunications and medical devices to automotive and aerospace.

In today’s competitive electronics landscape, speed and precision determine market success. Turnkey PCB Assembly offers an all-in-one solution that helps companies accelerate product launches while minimizing risks and overhead. It not only simplifies supply chain management but also enhances traceability, quality assurance, and customization capabilities.

The primary goal of Turnkey PCB Assembly is to deliver ready-to-use electronic boards that meet exact design specifications and global manufacturing standards. Whether for prototype runs or large-scale production, this model reduces time-to-market and ensures consistency across every batch.

Why Turnkey PCB Assembly Is Gaining Global Attention

The growing adoption of turnkey PCB services is driven by several factors reshaping global electronics manufacturing. Businesses are seeking smarter, more cost-efficient ways to develop complex products under tight deadlines, and turnkey assembly directly addresses these needs.

Key Benefits of Turnkey PCB Assembly:

| Feature | Description | Impact on Manufacturing |

|---|---|---|

| End-to-End Management | Handles every phase from design to final assembly. | Simplifies production and communication. |

| Component Sourcing | Uses reliable global component suppliers. | Ensures authenticity, reduces procurement time. |

| Cost Optimization | Eliminates multiple vendor markups. | Lowers overall production costs. |

| Faster Lead Times | Integrated workflow speeds up delivery. | Enhances competitiveness in fast-paced markets. |

| Quality Control | Implements automated optical inspection (AOI), functional testing, and X-ray inspection. | Guarantees defect-free performance. |

| Scalability | Suitable for both small prototype runs and mass production. | Provides flexibility for R&D and scaling needs. |

| Traceability & Transparency | Full project visibility via digital tracking systems. | Strengthens accountability and reliability. |

As industries evolve toward digital integration and IoT-driven systems, Turnkey PCB Assembly becomes essential for supporting high-density and high-performance circuit designs. Manufacturers can focus on innovation instead of logistics, while the assembly partner ensures precision at every stage.

Furthermore, sustainability is becoming a key differentiator. Turnkey PCB providers are increasingly adopting eco-friendly materials and energy-efficient manufacturing processes. This not only aligns with global environmental standards but also appeals to companies committed to reducing their carbon footprint.

How Turnkey PCB Assembly Works: From Design to Delivery

To fully appreciate the advantages of this model, it is vital to understand how the Turnkey PCB Assembly process operates. It is a systematic approach that integrates technology, logistics, and engineering expertise.

Step-by-Step Process:

-

Design Review and Engineering Consultation

The process begins with an evaluation of the Gerber files, Bill of Materials (BOM), and layout specifications. Engineers verify design compatibility, suggest cost-effective alternatives, and identify potential manufacturing challenges. -

Component Procurement

The assembly provider sources components directly from authorized distributors. Through advanced inventory management systems, shortages and counterfeit risks are minimized, ensuring each part meets performance standards. -

PCB Fabrication

The base boards are manufactured using precise layer stacking, copper plating, and solder mask application. Materials such as FR4, Rogers, or aluminum-based substrates are selected based on project requirements. -

Assembly Process (SMT & Through-Hole Technology)

-

Surface Mount Technology (SMT): Automated pick-and-place machines position components onto solder-pasted pads with micron-level accuracy.

-

Through-Hole Assembly: For components requiring stronger mechanical bonds, wave soldering and selective soldering techniques are applied.

-

-

Inspection and Testing

Quality assurance is maintained through multiple testing stages including AOI, X-ray inspection, In-Circuit Testing (ICT), and Functional Testing (FCT). Each assembled board undergoes electrical verification to ensure it meets specified standards. -

Packaging and Delivery

Once tested and approved, boards are packaged under anti-static and moisture-controlled conditions. They are then shipped as fully functional units ready for integration into the client’s final products.

Why This Process Enhances Reliability:

By centralizing all operations under one provider, errors caused by communication gaps, shipping delays, or incompatible specifications are eliminated. The synergy between design, sourcing, and production creates a streamlined workflow that ensures precision and repeatability.

Industry Applications:

-

Consumer Electronics

-

Medical Equipment

-

Automotive Control Systems

-

Aerospace and Defense

-

Industrial Automation

-

Renewable Energy Devices

Each sector demands unique design and compliance requirements. Turnkey assembly services adapt to these needs by offering customized production lines, material selections, and certification support such as ISO, IPC-A-610, and RoHS compliance.

The Future of Turnkey PCB Assembly: Trends and Innovations

The future of PCB manufacturing is being shaped by automation, digitalization, and global collaboration. Turnkey PCB Assembly stands at the center of these advancements, paving the way for next-generation electronics.

Key Future Trends:

-

Smart Manufacturing Integration:

Factories are adopting AI-powered monitoring systems and data analytics to optimize yield and predict potential failures. Real-time feedback loops enable continuous improvement in production quality. -

Miniaturization and High-Density Interconnects (HDI):

With consumer electronics demanding thinner and faster devices, HDI PCBs and micro-vias are becoming industry standards. Turnkey providers are investing in advanced drilling and lamination technologies to meet these expectations. -

Flexible and Rigid-Flex PCB Demand:

Wearable devices, foldable smartphones, and compact medical sensors are driving demand for flexible PCBs. Turnkey manufacturers are refining their processes to ensure durability and bend tolerance in these designs. -

Sustainability and Green Manufacturing:

Eco-conscious production is no longer optional. Companies now favor turnkey partners that use recyclable materials, lead-free soldering, and energy-efficient equipment. -

Global Supply Chain Resilience:

The post-pandemic manufacturing ecosystem emphasizes reliable logistics and local sourcing. Turnkey PCB Assembly providers that diversify their supply chains can guarantee uninterrupted delivery even in volatile markets.

Economic and Technological Impact:

As global demand for electronics rises, the turnkey model will redefine how innovation reaches the market. By combining automation, skilled labor, and efficient procurement, manufacturers can achieve both cost reduction and superior quality assurance. Turnkey PCB Assembly is no longer just a convenience—it is becoming the backbone of modern electronic production.

Frequently Asked Questions (FAQ)

Q1: What distinguishes Turnkey PCB Assembly from partial or consigned PCB assembly?

A1: In a consigned assembly, the customer provides all materials and components, while the manufacturer only handles assembly. In contrast, Turnkey PCB Assembly covers every aspect—from material sourcing and fabrication to final testing. This reduces management complexity, ensures consistent quality, and accelerates production timelines.

Q2: How does a Turnkey PCB Assembly provider ensure the authenticity of electronic components?

A2: Leading turnkey providers maintain long-term partnerships with certified distributors and component manufacturers. They use traceable procurement systems, conduct rigorous supplier audits, and perform quality checks such as X-ray and decapsulation testing. This guarantees that every component is genuine and compliant with international standards.

Partnering with Fanway for Complete Turnkey PCB Solutions

Turnkey PCB Assembly represents the future of efficient, high-quality electronic production. Its ability to integrate design, sourcing, and assembly under one roof eliminates barriers between concept and market-ready product. As industries continue to demand faster innovation and higher precision, this comprehensive model becomes indispensable.

Fanway has established itself as a trusted provider of advanced Turnkey PCB Assembly services. With extensive engineering expertise, cutting-edge facilities, and a commitment to quality assurance, Fanway supports clients through every phase of electronic product development—from prototype to large-scale production.

For businesses seeking reliability, speed, and innovation in PCB manufacturing, Fanway offers a partnership that delivers measurable results.

Contact us today to learn more about our Turnkey PCB Assembly capabilities and how our integrated solutions can accelerate your next project.