What Makes Rigid Flex PCB Essential for Modern Electronics?

2026-01-05

In today's fast-evolving electronics industry, Rigid Flex PCB has emerged as a game-changer, combining the benefits of both rigid and flexible circuit boards. Unlike traditional rigid PCBs, Rigid Flex PCB offers unmatched versatility, reliability, and space-saving advantages, making it a preferred choice for advanced electronics in aerospace, medical devices, wearable technology, and consumer electronics. At Shenzhen Fanway Technology Co., Ltd, we specialize in designing and manufacturing high-quality Rigid Flex PCBs tailored to your project's unique needs.

What is a Rigid Flex PCB?

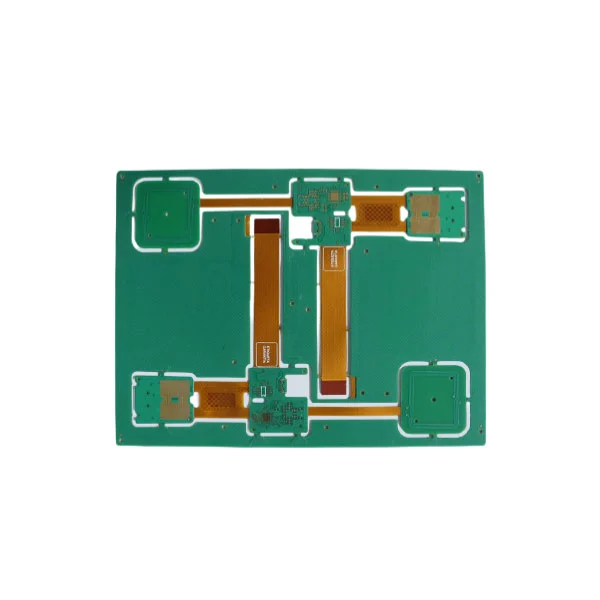

A Rigid Flex PCB is a hybrid circuit board that integrates flexible and rigid substrates into a single assembly. The rigid sections provide structural support and stable component mounting, while the flexible sections allow bending, folding, and dynamic movement. This combination allows for compact and lightweight designs without compromising electrical performance or reliability.

Key Advantages of Rigid Flex PCB

-

Space-Saving Design: Ideal for compact devices where traditional PCBs cannot fit.

-

Enhanced Reliability: Flexible sections reduce stress and vibration on solder joints.

-

Weight Reduction: Combines multiple rigid boards into one flexible assembly.

-

Improved Performance: Reduced interconnects and connectors lead to better signal integrity.

-

Design Flexibility: Supports complex 3D structures in modern electronic products.

| Feature | Benefit |

|---|---|

| Rigid Section | Stable component mounting, mechanical support |

| Flexible Section | Allows bending and folding for space-saving designs |

| Material | High-performance polyimide or FR4 substrates |

| Layer Count | Customizable to meet complex circuitry needs |

How Does Rigid Flex PCB Work in Electronics?

The flexible layers in a Rigid Flex PCB act as interconnections between rigid boards. By eliminating traditional connectors, Rigid Flex PCBs reduce potential failure points and improve signal performance. This makes them particularly useful in devices with moving parts, tight spaces, or wearable electronics. For instance, in medical imaging equipment, flexible sections can absorb mechanical stress, enhancing durability and reliability.

Rigid Flex PCB vs. Traditional PCB

| Comparison | Rigid Flex PCB | Traditional PCB |

|---|---|---|

| Flexibility | Can bend and fold | Completely rigid |

| Space Efficiency | High, suitable for compact designs | Limited by size |

| Reliability | High, fewer solder joint failures | Moderate, more connectors needed |

| Cost | Higher initial cost | Lower cost |

| Application Scope | Aerospace, medical, wearables | Consumer electronics, simple devices |

Applications of Rigid Flex PCB

-

Medical Devices: Compact, reliable, and wearable instruments.

-

Aerospace & Defense: High-performance, vibration-resistant designs.

-

Consumer Electronics: Smartphones, tablets, and wearable gadgets.

-

Automotive Industry: Advanced driver-assistance systems (ADAS) and infotainment systems.

Why Choose Shenzhen Fanway Technology Co., Ltd for Rigid Flex PCB?

At Shenzhen Fanway Technology Co., Ltd, we offer end-to-end Rigid Flex PCB solutions, from design and prototyping to full-scale production. Our products are engineered to meet high reliability standards, with strict quality control and competitive pricing. We leverage advanced manufacturing techniques to produce multilayer Rigid Flex PCBs that optimize performance while minimizing size and weight.

Key Services

-

Custom Rigid Flex PCB design

-

Prototype and small-batch production

-

Full-scale manufacturing

-

Quality assurance and testing

Conclusion

Rigid Flex PCB is no longer a luxury but a necessity for modern, compact, and high-performance electronics. By integrating rigid and flexible substrates, these PCBs provide unmatched durability, flexibility, and space efficiency. Choosing Shenzhen Fanway Technology Co., Ltd ensures you get expert guidance, high-quality production, and reliable delivery for all your Rigid Flex PCB needs.

Contact us today to discuss your project requirements and discover how our Rigid Flex PCBs can enhance your product performance.