What Makes Printed Circuit Board Assembly Crucial for Modern Electronics?

2025-12-25

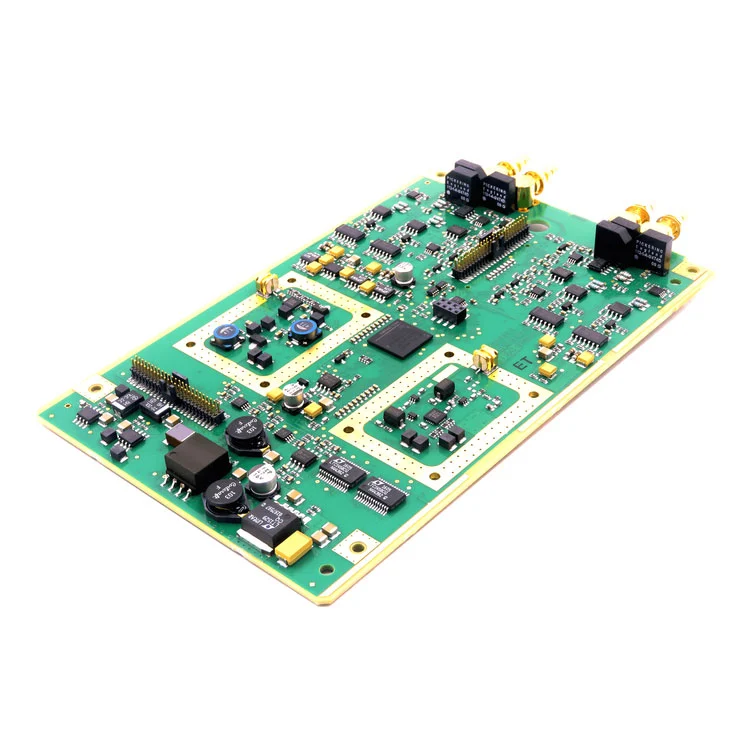

Printed Circuit Board Assembly (PCBA) is the backbone of modern electronics. From smartphones to industrial machinery, the efficiency, reliability, and precision of a device heavily depend on the quality of its PCB assembly. At Shenzhen Fanway Technology Co., Ltd, we specialize in delivering top-notch PCB assembly services that ensure your electronic products perform flawlessly in every application.

PCB assembly involves mounting and soldering electronic components onto a PCB substrate to create functional circuits. This process is crucial because even minor errors during assembly can lead to device malfunctions, product recalls, or increased production costs.

The Role of Printed Circuit Board Assembly

Printed Circuit Board Assembly plays several essential roles in electronics manufacturing:

-

Integration of Components – Ensures all electronic parts such as resistors, capacitors, ICs, and connectors are correctly placed and electrically connected.

-

Quality and Reliability – Reduces the risk of circuit failures through precise soldering techniques and quality inspections.

-

Product Miniaturization – Enables compact designs without compromising performance, vital for modern portable devices.

-

Cost Efficiency – Streamlines manufacturing by minimizing errors and rework.

| PCBA Process Stage | Purpose |

|---|---|

| SMT (Surface Mount Tech) | Mounts small components quickly and efficiently |

| Through-Hole Assembly | Ensures mechanical stability for heavy components |

| Testing & Inspection | Verifies functionality and detects defects |

| Final Assembly | Completes the product with connectors, casing, etc. |

Why Choose Shenzhen Fanway Technology Co., Ltd for PCBA?

-

High Precision Manufacturing – Using advanced SMT machines, our assemblies maintain strict tolerance levels for consistent quality.

-

Comprehensive Services – From prototyping to mass production, we provide end-to-end PCB assembly solutions.

-

Expert Team – Our engineers possess years of experience in optimizing circuit layouts and assembly processes.

-

Quality Assurance – Each PCBA undergoes rigorous testing including AOI, X-ray inspection, and functional verification to ensure reliability.

PCB Assembly vs. Traditional Wiring: Which is Better?

While traditional wiring uses point-to-point connections, PCB assembly offers numerous advantages:

| Feature | PCB Assembly | Traditional Wiring |

|---|---|---|

| Space Efficiency | High – compact designs possible | Low – bulky connections |

| Production Speed | Fast with automation | Slow and labor-intensive |

| Reliability | High with minimal defects | Prone to human error |

| Maintenance | Easy to trace faults | Harder to diagnose |

Clearly, PCB assembly is the preferred choice for modern electronics due to its efficiency, reliability, and scalability.

The Importance of PCBA in Product Performance

A well-assembled PCB not only ensures that electronic devices function as intended but also enhances product longevity and reduces warranty costs. For companies aiming to deliver premium electronics, choosing the right PCBA partner is critical. Shenzhen Fanway Technology Co., Ltd combines industry expertise with cutting-edge technology to deliver PCBA solutions that meet both technical and business needs.

Conclusion

In conclusion, Printed Circuit Board Assembly is vital for the success of modern electronics, influencing product performance, reliability, and manufacturing efficiency. Partnering with a professional provider like Shenzhen Fanway Technology Co., Ltd ensures your projects are executed with precision and expertise. For high-quality, reliable, and cost-effective PCB assembly solutions, contact us today to discuss your requirements and start your next electronics project with confidence.