What Makes Plastic Mold Design the Core of Modern Manufacturing?

2025-10-15

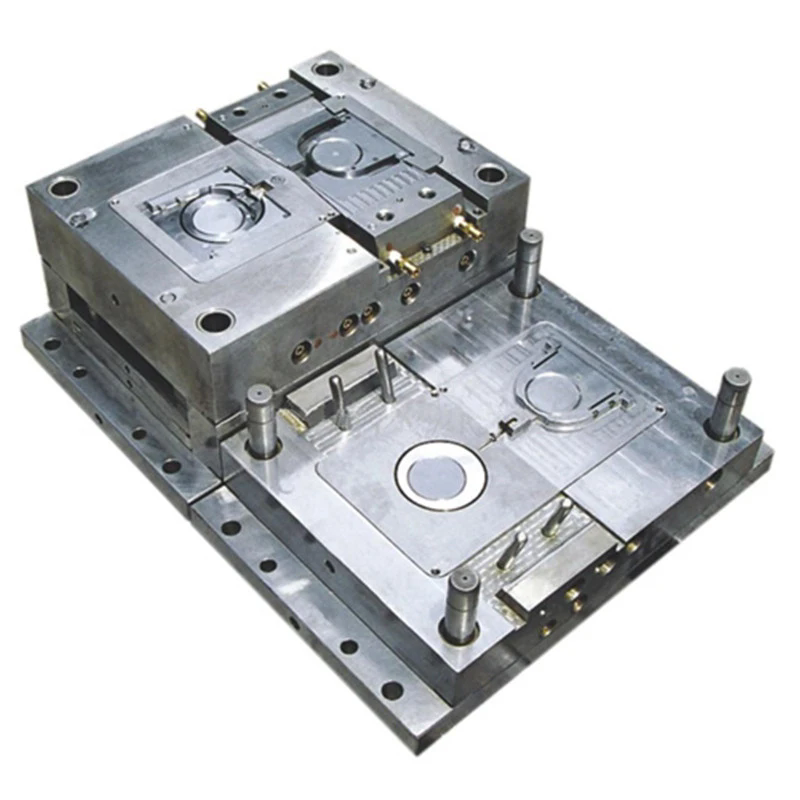

Plastic mold design lies at the heart of the manufacturing process for countless products used in daily life—from automotive components and medical devices to consumer electronics and household goods. It is the blueprint that transforms molten plastic into precisely shaped parts with consistent quality and durability.

Plastic mold design refers to the engineering process of creating the mold—a specialized tool used in injection molding machines to shape plastic materials. The design determines the part’s accuracy, surface quality, structural integrity, and production efficiency. As industries push for higher performance and lighter materials, advanced mold design has become a key differentiator for competitive production.

In the modern market, precision mold design is not just about creating a cavity for plastic—it’s about integrating innovation, material science, and cost efficiency. A well-engineered plastic mold design can significantly reduce cycle times, minimize material waste, and enhance the final product’s mechanical and aesthetic properties.

How Does the Plastic Mold Design Process Work?

The process of designing a plastic mold involves several key stages—each requiring a balance between creative engineering and technical precision. Understanding this workflow helps explain why high-quality mold design can make or break a manufacturing project.

Step-by-Step Plastic Mold Design Process

| Stage | Description | Technical Focus |

|---|---|---|

| 1. Product Analysis | Evaluating the part’s geometry, functionality, and material requirements. | Identifying potential shrinkage, warpage, and weak points. |

| 2. Mold Type Selection | Choosing the mold type (single cavity, multi-cavity, family mold, etc.) based on production needs. | Balancing production volume with cost efficiency. |

| 3. Parting Line and Ejection System Design | Determining how the part will be separated and ejected from the mold. | Preventing deformation or surface defects. |

| 4. Cooling System Layout | Designing optimal cooling channels to control temperature distribution. | Improving cycle time and dimensional stability. |

| 5. Venting and Gating System Design | Managing air escape and material flow. | Ensuring complete filling and minimizing weld lines. |

| 6. Mold Material Selection | Choosing suitable steel or aluminum grades for the mold base and cavity inserts. | Balancing hardness, corrosion resistance, and machining performance. |

| 7. Simulation and Validation | Running mold flow analysis to predict performance before manufacturing. | Detecting potential problems and optimizing design parameters. |

| 8. Mold Manufacturing and Assembly | CNC machining, polishing, and fitting of components. | Ensuring precision alignment and smooth operation. |

| 9. Trial and Testing | Conducting mold trials to evaluate part quality and consistency. | Adjusting parameters for production readiness. |

Each stage builds upon the previous one, ensuring the final mold achieves optimal productivity and part accuracy. With the rise of digital simulation tools, designers can now detect potential issues such as short shots, sink marks, or air traps before cutting any steel—saving both time and cost.

Why Is Precision Plastic Mold Design Key to Product Quality and Cost Efficiency?

The quality of a plastic product depends heavily on the precision of its mold. Even minor design errors can lead to defects, rework, or wasted materials. High-performance mold design ensures not only superior product quality but also operational efficiency throughout the manufacturing cycle.

Key Advantages of Advanced Plastic Mold Design

-

Dimensional Accuracy:

Tight tolerance control ensures each part fits perfectly with other components, which is crucial in automotive, electronics, and medical applications. -

Improved Surface Finish:

Polished mold cavities or textured finishes allow manufacturers to achieve aesthetic consistency and eliminate secondary surface treatments. -

Shorter Cycle Times:

Efficient cooling layouts and optimized gate locations reduce molding time, improving throughput and energy savings. -

Material Optimization:

Modern simulation software allows engineers to reduce material waste and ensure consistent material flow, improving both sustainability and profitability. -

Longer Mold Lifespan:

Proper selection of mold materials and coatings extends the operational life of the tool, reducing long-term costs. -

Reduced Maintenance:

A well-designed mold minimizes wear, ensuring stable performance over millions of production cycles. -

Sustainability and Energy Efficiency:

With optimized thermal management and lightweighting strategies, modern mold design contributes to lower energy consumption and eco-friendly production.

The Role of Technology in Mold Design Innovation

Technological advancements such as CAD/CAM systems, AI-driven simulation, and 3D printing have revolutionized how molds are conceptualized and built. Engineers can now test virtual prototypes before fabrication, drastically cutting development time. Moreover, automation and precision machining have enabled molds with micro-features and complex geometries—once impossible to achieve by conventional means.

As industries move toward smart manufacturing, integrating digital twins and data-driven design will further enhance precision and repeatability. These innovations are setting the stage for a new era of efficiency and customization in mold design.

What Are the Common Challenges and Future Trends in Plastic Mold Design?

Challenges in Mold Design

Despite the technological progress, mold design still faces several key challenges:

-

Complex Geometry: Increasing demand for intricate parts requires advanced tooling strategies.

-

Thermal Management: Uneven cooling can cause deformation and stress concentration.

-

Material Compatibility: Selecting the right combination of mold and plastic materials remains critical.

-

Cost Control: Precision molds can be expensive; poor design choices may lead to costly reworks.

-

Cycle Time Reduction: Manufacturers constantly seek shorter cycles without compromising quality.

Future Trends in Plastic Mold Design

-

Digital Twin Integration:

Future mold systems will employ real-time digital replicas to monitor wear, predict failure, and improve efficiency. -

Additive Manufacturing for Mold Components:

3D-printed conformal cooling channels enable optimized temperature control, reducing cycle times and improving quality. -

Sustainable Materials and Processes:

Eco-friendly polymers and recyclable mold materials are gaining traction to meet environmental standards. -

AI and Machine Learning in Design Optimization:

Predictive modeling tools will allow designers to automatically refine gate positions, cooling systems, and ejection mechanisms. -

Global Customization:

As markets diversify, mold designs will be tailored for specific regional needs and product variations, increasing flexibility and responsiveness.

These innovations indicate that plastic mold design will continue to be a strategic asset for companies aiming for global competitiveness. Efficient, automated, and data-driven mold design will define the next generation of manufacturing excellence.

Common FAQs About Plastic Mold Design

Q1: What factors determine the lifespan of a plastic mold?

A1: The mold lifespan depends on factors such as the choice of mold material, the type of plastic processed, operating temperature, cycle time, and maintenance practices. High-quality tool steels (like H13 or S136) combined with proper heat treatment and regular maintenance can ensure molds last for millions of cycles without significant wear.

Q2: How can mold design reduce production defects?

A2: Proper gating and venting design, uniform wall thickness, and balanced cooling channels help eliminate defects like sink marks, warpage, and air traps. Mold flow analysis during the design phase allows engineers to predict and correct potential issues before production, ensuring consistent part quality.

The Future of Mold Design Excellence with Aicheng

Plastic mold design stands as a cornerstone of modern production—uniting engineering precision, cost control, and innovation. As industries evolve toward smarter and more sustainable manufacturing, the demand for efficient, long-lasting, and digitally optimized mold designs will continue to rise.

Aicheng is at the forefront of this transformation, delivering comprehensive mold design solutions that combine advanced simulation, precision engineering, and durable tooling materials. The company’s commitment to quality and innovation ensures clients achieve the highest production efficiency and part accuracy.

To explore how Aicheng’s expertise in Plastic Mold Design can enhance your manufacturing process, contact us today for professional consultation and customized solutions tailored to your production needs.