What Makes Heavy Copper PCB Essential for High-Power Electronics?

2026-01-08

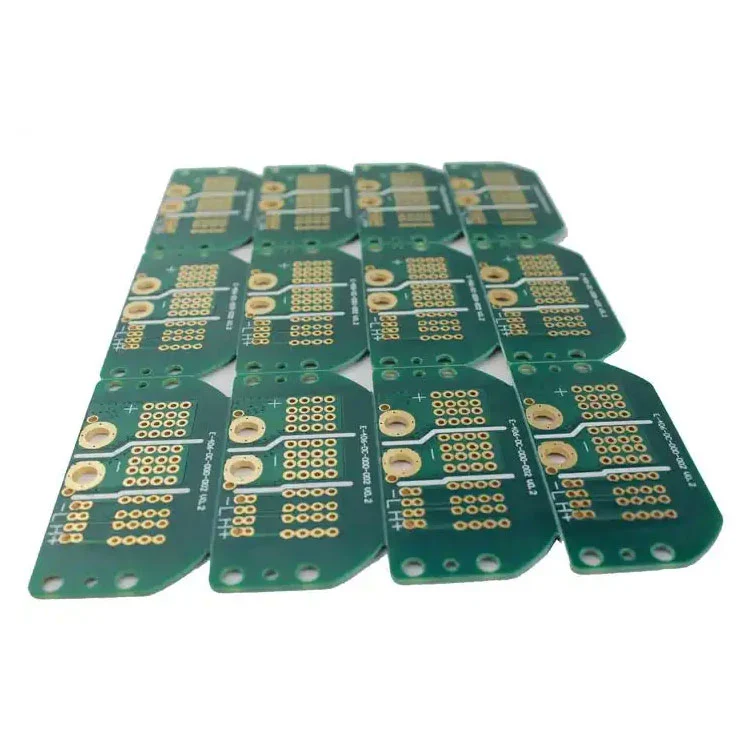

In modern electronics, as devices demand higher power and efficiency, standard PCBs often fall short in handling heat dissipation and current capacity. Heavy Copper PCB has emerged as a critical solution for industries such as power electronics, automotive, aerospace, and renewable energy. Shenzhen Fanway Technology Co., Ltd specializes in designing and manufacturing high-quality heavy copper PCBs that meet strict industry standards and deliver superior performance.

Heavy copper PCBs differ from regular PCBs primarily in their copper thickness. While standard PCBs usually have copper weights of 1 oz/ft² (35 μm), heavy copper PCBs can range from 3 oz/ft² (105 μm) to over 10 oz/ft² (350 μm), providing enhanced conductivity and heat handling capabilities.

Why Choose Heavy Copper PCB Over Standard PCB?

Heavy copper PCBs offer multiple advantages that make them indispensable in high-power applications:

| Feature | Heavy Copper PCB | Standard PCB |

|---|---|---|

| Copper Thickness | 3–10+ oz/ft² | 1 oz/ft² |

| Current Capacity | Up to 100+ A | 1–10 A |

| Heat Dissipation | Excellent | Moderate |

| Mechanical Strength | High | Moderate |

| Cost | Higher | Lower |

The thicker copper not only allows for higher current handling but also improves thermal management, reducing the risk of overheating and enhancing reliability.

Applications of Heavy Copper PCB

Heavy copper PCBs are widely used in industries where high current or heat management is critical:

-

Power Supplies: Efficiently conduct large currents while preventing voltage drops.

-

Automotive Electronics: Supports electric vehicles and hybrid systems with high power loads.

-

Industrial Equipment: Ideal for welding machines, motor controllers, and power converters.

-

Aerospace & Defense: Ensures reliability in extreme temperature and vibration conditions.

Shenzhen Fanway Technology Co., Ltd provides tailored solutions for these applications, offering both single-sided and multi-layer heavy copper PCB designs with precise specifications.

How Heavy Copper PCB Enhances Performance

The impact of heavy copper PCBs is seen in three main areas:

-

Electrical Performance: Thicker copper traces reduce resistance, improve voltage stability, and enable higher current flows.

-

Thermal Management: Enhanced heat dissipation prevents components from overheating, increasing lifespan.

-

Mechanical Reliability: Thicker copper and reinforced substrates reduce warping and improve durability under harsh environments.

Best Practices When Using Heavy Copper PCB

To fully leverage the advantages of heavy copper PCBs, manufacturers should consider:

-

Proper thermal design and copper routing to avoid hotspots.

-

Using appropriate surface finishes like ENIG or HASL for solderability.

-

Consulting experienced manufacturers, like Shenzhen Fanway Technology Co., Ltd, to optimize layer stackups and copper weights.

Heavy Copper PCB vs Aluminum PCB: Which Is Better?

While Aluminum PCBs are often chosen for thermal management, heavy copper PCBs outperform them in current carrying capacity and mechanical strength. Aluminum PCBs are lighter and cost-effective for LED applications, but for high-current or industrial electronics, heavy copper PCBs remain the superior choice.

Comparison Table:

| Feature | Heavy Copper PCB | Aluminum PCB |

|---|---|---|

| Current Capacity | Very High | Moderate |

| Heat Dissipation | Excellent | Good |

| Durability | High | Moderate |

| Cost | Higher | Moderate |

| Application | Power electronics, Industrial | LED lighting, Consumer electronics |

Conclusion

Choosing the right PCB is crucial for performance, reliability, and safety in high-power electronics. Heavy Copper PCB provides exceptional electrical, thermal, and mechanical benefits, making it a preferred solution for critical industries. Shenzhen Fanway Technology Co., Ltd combines advanced manufacturing techniques with strict quality control to deliver premium heavy copper PCBs customized to client needs.

For high-performance, durable, and reliable PCB solutions, contact us at Shenzhen Fanway Technology Co., Ltd to discuss your project requirements and explore our full range of heavy copper PCB options.