What Makes Healthcare PCBA the Core of Modern Medical Devices?

2025-11-11

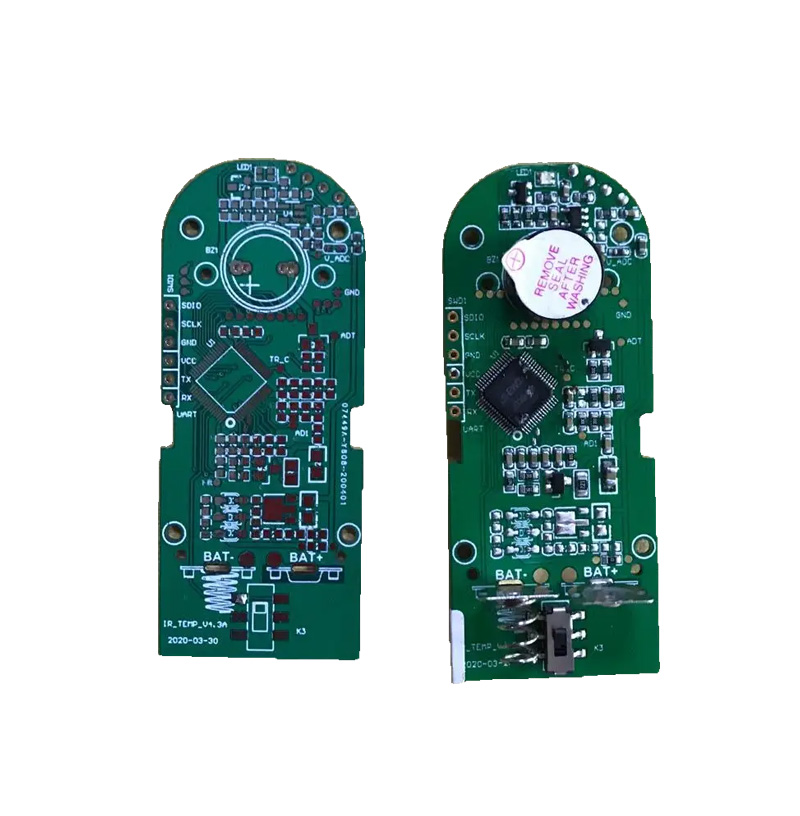

Healthcare PCBA is the heart of modern medical electronics. It integrates various electronic components—such as resistors, capacitors, sensors, and microcontrollers—onto a printed circuit board, enabling medical devices to operate with high precision and reliability. From diagnostic tools like ECG machines and MRI scanners to life-support systems and portable medical monitors, Healthcare PCBA ensures every signal and function is executed flawlessly.

In today’s healthcare sector, precision and reliability are critical. A minor failure in a circuit can result in inaccurate readings or device malfunction, which is why Healthcare PCBA is designed to meet strict standards such as ISO 13485, IPC Class 3, and RoHS compliance. These standards guarantee safety, functionality, and durability under demanding medical environments.

The growing integration of electronics into healthcare equipment—especially with the rise of smart healthcare and telemedicine—makes PCBAs indispensable. They serve as the backbone of communication, control, and data processing in all advanced medical technologies.

Key Product Parameters of Healthcare PCBA

| Parameter Category | Specification Highlights |

|---|---|

| Base Material | FR4, Polyimide, Rogers, Aluminum-based substrate |

| Layer Count | 1–32 layers |

| Copper Thickness | 1 oz to 6 oz |

| Surface Finish | ENIG, HASL, OSP, Immersion Silver/Tin |

| Solder Mask | Green, Blue, Black, White, Custom colors |

| Component Types | SMT, Through-hole, Mixed assembly |

| Testing Methods | ICT, AOI, Flying Probe, X-ray inspection |

| Compliance Standards | ISO 13485, RoHS, IPC-A-610, UL certification |

| Applications | Diagnostic devices, patient monitors, implant systems, lab analyzers, wearable medical devices |

Healthcare PCBA products are developed with extreme attention to signal integrity, low electromagnetic interference (EMI), and stable performance under sterilization conditions. This allows them to be used in life-critical equipment, ensuring consistent reliability and data accuracy.

Why Is Healthcare PCBA Crucial for Reliability and Innovation in Medical Devices?

The significance of Healthcare PCBA goes beyond simple electronic connectivity. It represents the foundation of medical innovation, directly impacting diagnostic accuracy, patient safety, and device miniaturization.

a. Precision and Reliability in Life-Saving Applications

Medical devices require zero tolerance for failure. A PCBA malfunction in a ventilator or defibrillator can lead to serious consequences. Healthcare PCBA is engineered with tight design tolerances, advanced thermal management, and high-quality solder joints to prevent operational errors and ensure continuous performance over time.

b. Miniaturization for Portable and Wearable Medical Devices

As medical technology advances, there is a strong trend toward portable and wearable devices. Miniaturized PCBAs with high-density interconnect (HDI) and flexible substrates allow medical manufacturers to build smaller, lighter devices that patients can wear comfortably for continuous health monitoring.

c. Data Integration and Smart Healthcare

With the rise of the Internet of Medical Things (IoMT), Healthcare PCBAs enable smart connectivity through embedded microprocessors and communication modules such as Wi-Fi, Bluetooth, or 5G. These PCBAs transmit real-time patient data securely to healthcare systems, improving diagnostics and enabling predictive healthcare.

d. Durability in Critical Conditions

Healthcare environments often involve exposure to sterilization, temperature fluctuations, and humidity. To withstand these conditions, Healthcare PCBAs use moisture-resistant materials and conformal coatings, ensuring stable performance even under repeated sterilization cycles.

e. High-Level Testing and Quality Control

Each Healthcare PCBA undergoes automated optical inspection (AOI), in-circuit testing (ICT), and X-ray analysis. These tests confirm that every component and solder joint meets the design specification, offering traceability and compliance for regulatory approvals.

How Are Healthcare PCBAs Shaping the Future of Medical Technology?

The next decade will see Healthcare PCBA technology driving the digital transformation of healthcare systems. With continuous innovation, PCBAs are becoming smarter, more compact, and more energy-efficient.

a. Trend Toward Flexible and Rigid-Flex PCBAs

Flexible PCBAs are now being integrated into curved medical instruments and wearable healthcare solutions. Their flexibility allows for greater design freedom, reducing assembly space and enhancing comfort in devices like insulin pumps or cardiac monitoring patches.

b. Increased Role in AI-Assisted Diagnostics and Robotics

Modern PCBAs with embedded processors are supporting AI-based medical systems. They enable image analysis, automated testing, and robotic-assisted surgeries with faster processing and precise control, laying the groundwork for next-generation medical robotics.

c. Sustainability and Eco-Friendly Manufacturing

Environmental awareness in healthcare production is growing. Manufacturers are adopting RoHS and REACH-compliant materials, halogen-free laminates, and recyclable substrates to minimize ecological impact while maintaining high electrical performance.

d. Integration of Sensor and Communication Technologies

Future PCBAs are expected to integrate biosensors, MEMS, and wireless communication modules to collect and transmit critical data instantly. These systems will empower doctors with continuous real-time monitoring, enhancing preventive care and patient management.

e. Global Collaboration and Standardization

As medical technology becomes more interconnected, standardized Healthcare PCBA design and global certifications will be vital. This ensures that devices can operate safely and reliably across international markets without performance disparities.

Common FAQs About Healthcare PCBA

Q1: What challenges are involved in designing PCBAs for medical applications?

A1: Designing PCBAs for healthcare requires balancing size, power efficiency, and safety. Medical devices must meet strict regulatory standards (such as ISO 13485 and FDA requirements) while maintaining flawless performance. Engineers must design layouts that reduce electromagnetic interference, ensure thermal stability, and allow easy sterilization. The challenge lies in creating compact designs without compromising durability or data accuracy.

Q2: How do manufacturers ensure the reliability of Healthcare PCBA?

A2: Manufacturers apply multiple stages of quality control, including visual inspection, AOI, ICT, and X-ray testing. They also perform functional tests under temperature and humidity stress to simulate real-life medical environments. Traceability systems record every component used, ensuring compliance and consistency across production batches.

How Can Healthcare PCBA Contribute to the Future of Global Health?

Healthcare PCBA will continue to be a driving force behind healthcare innovation. Its evolution supports the move toward personalized medicine, enabling real-time data analysis, remote diagnostics, and patient-centered care. By improving connectivity between devices and healthcare systems, PCBAs contribute to faster diagnosis, efficient hospital workflows, and better patient outcomes.

Moreover, as 5G technology and IoT networks expand, Healthcare PCBAs will facilitate seamless communication between smart medical systems worldwide. These advancements will accelerate early detection of diseases, improve medical imaging accuracy, and enable continuous remote patient monitoring.

In the future, the integration of nanotechnology and flexible electronics into Healthcare PCBAs will make medical devices more adaptive, intelligent, and eco-efficient. This progress will enhance medical precision and create opportunities for innovation in global health infrastructure.

About Unixplore — Your Trusted Partner in Healthcare PCBA Solutions

Unixplore stands as a professional provider of high-quality Healthcare PCBA solutions, serving global medical equipment manufacturers with precision, stability, and innovation. Each PCBA is designed under rigorous quality control and compliant with international healthcare standards. Unixplore’s advanced assembly lines, skilled engineering teams, and commitment to excellence make it a preferred partner for developing reliable and efficient medical devices.

From prototype development to large-scale production, Unixplore ensures each Healthcare PCBA delivers exceptional electrical performance, durability, and safety. The company continuously invests in research and technological upgrades to meet the evolving needs of the medical industry.

For partnerships, custom PCBA development, or technical inquiries, contact us today to learn how Unixplore can empower your next-generation healthcare innovations.