What Makes HDI PCB the Key to Next-Generation Electronic Performance?

2025-10-31

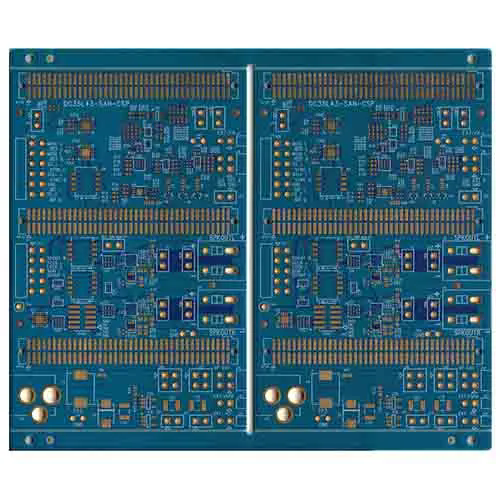

In the rapidly evolving electronics industry, the demand for smaller, faster, and more efficient devices continues to drive innovation in printed circuit board (PCB) design. Among the most transformative technologies shaping this evolution is the HDI PCB, or High-Density Interconnect Printed Circuit Board.

HDI PCBs are designed to pack more wiring, components, and functionality into a smaller footprint than traditional PCBs. This is achieved through the use of microvias, laser-drilled holes, and multiple layers of interconnections that allow for higher circuit density. The result is a lightweight, compact board that supports high-speed signal transmission and excellent electrical performance — essential for applications in smartphones, medical devices, automotive electronics, aerospace systems, and advanced computing.

But what makes HDI PCB technology stand out? Its superiority lies in the ability to integrate more functionality while reducing size and improving performance. By minimizing signal loss and maintaining high reliability under demanding conditions, HDI PCBs are paving the way for the next generation of intelligent, miniaturized electronics.

Why HDI PCB is Transforming Modern Electronics

The advantages of HDI PCB technology extend far beyond miniaturization. From performance optimization to durability and flexibility, HDI boards are redefining the standards of modern electronic design.

Key Advantages of HDI PCB:

| Feature | Description | Benefits |

|---|---|---|

| High Circuit Density | Enables more components to be placed per unit area using microvias and fine traces. | Compact design with increased performance capability. |

| Enhanced Electrical Performance | Reduced signal delay and cross-talk due to shorter trace lengths and smaller vias. | Improved speed and data integrity. |

| Lightweight Design | Uses thinner materials and fewer layers while maintaining performance. | Ideal for portable and wearable devices. |

| Reliable Interconnects | Laser-drilled microvias ensure stable electrical connections even under stress. | Long-lasting and high-reliability solutions. |

| Thermal Management | Efficient heat dissipation materials prevent overheating. | Extends component lifespan and ensures consistent performance. |

| Design Flexibility | Supports both rigid and flexible PCB configurations. | Adaptable to complex product architectures. |

These benefits explain why HDI PCBs are now the backbone of innovation in industries such as telecommunications, automotive radar systems, IoT devices, and aerospace navigation modules.

How HDI PCB Enables High-Performance Designs

The key lies in the stack-up structure of HDI boards, which allows designers to create multiple interconnection layers with microvias that connect directly between them. These microvias reduce the need for long conductive paths, minimizing signal distortion and improving current flow. Additionally, HDI designs can include blind and buried vias, enhancing routing efficiency and allowing greater design freedom for engineers developing complex multilayer circuits.

With data transfer rates and miniaturization pushing limits, HDI PCB technology provides the foundation for high-speed, high-frequency, and high-reliability electronic performance that standard PCBs simply cannot match.

How HDI PCB Supports Innovation and Future Trends

As global industries pivot toward advanced digitalization and connectivity, HDI PCB technology is expected to play a crucial role in shaping future developments. Emerging technologies such as 5G communications, artificial intelligence (AI), autonomous driving, and wearable health devices all rely heavily on PCBs with superior electrical and mechanical capabilities.

Future Trends Driving HDI PCB Development

-

Integration with 5G and Beyond

HDI PCBs enable higher data bandwidth and faster signal transmission required for 5G base stations, routers, and IoT-enabled devices. Their low-loss dielectric materials support millimeter-wave frequencies with minimal interference. -

Rise of Miniaturized Consumer Electronics

The consumer electronics market continues to shrink device dimensions without compromising functionality. HDI PCBs make this possible by allowing component embedding and three-dimensional interconnects. -

Adoption in Automotive Electronics

Electric and autonomous vehicles rely on HDI PCBs for control modules, radar sensors, and infotainment systems. The ability to operate under extreme thermal and mechanical stress makes HDI boards indispensable in the automotive industry. -

Medical and Aerospace Applications

In mission-critical environments like aerospace and healthcare, reliability and compactness are paramount. HDI PCBs ensure stability and consistent signal integrity, vital for navigation, life-support, and diagnostic systems. -

Eco-Friendly and Sustainable Manufacturing

Advanced HDI PCB fabrication reduces material waste and energy consumption. The development of lead-free, halogen-free, and recyclable materials aligns with global sustainability goals.

By combining miniaturization, performance, and environmental responsibility, HDI PCBs are becoming the foundation for sustainable innovation in electronic design.

Common Questions About HDI PCB

Q1: What makes HDI PCB different from standard multilayer PCBs?

A1: Unlike conventional PCBs that rely on mechanically drilled vias and larger trace widths, HDI PCBs use laser-drilled microvias, thinner dielectric layers, and finer line spacing. This structure allows for higher component density, shorter signal paths, and improved electrical performance. In short, HDI boards deliver superior signal integrity and compactness that traditional PCBs cannot achieve.

Q2: How is the quality of HDI PCB measured?

A2: The quality of an HDI PCB is determined by several factors, including via integrity, layer alignment accuracy, impedance control, and signal loss levels. Reliable HDI manufacturers ensure precision drilling, clean microvia walls, and high-yield lamination processes to guarantee electrical reliability and mechanical stability. Advanced inspection techniques such as X-ray analysis and automated optical inspection (AOI) are also employed to maintain stringent quality standards.

Why Choose HDI PCB for Your Next Project

HDI PCBs are no longer limited to high-end applications; they have become essential in virtually every sector of electronics manufacturing. Companies that adopt HDI PCB technology gain a competitive edge through improved design efficiency, reduced production time, and enhanced product performance.

Key Takeaways:

-

HDI PCB technology supports ultra-compact, high-speed, and reliable electronic systems.

-

It is ideal for industries that demand miniaturization without compromising performance.

-

With future trends emphasizing connectivity, energy efficiency, and intelligent design, HDI PCBs will continue to define the future of electronics.

Viafull — Your Trusted HDI PCB Manufacturing Partner

As the demand for HDI PCB continues to rise across industries, choosing the right manufacturing partner is critical. Viafull stands out with its advanced production capabilities, precision engineering, and commitment to quality. The company specializes in fabricating high-density, multi-layer HDI boards with superior electrical and thermal performance that meet the most demanding design specifications.

Viafull’s engineering team leverages state-of-the-art laser drilling, automated inspection, and environmentally sustainable processes to ensure every PCB meets international standards for reliability and efficiency. Whether for 5G communication systems, wearable devices, or aerospace applications, Viafull delivers solutions that push the boundaries of modern technology.

For businesses seeking high-performance HDI PCB solutions, now is the time to take the next step.

Contact us to discuss your project requirements and discover how Viafull can help bring your next-generation electronics to life