What Makes Electronic Manufacturing Service the Backbone of Technology?

2025-09-25

Electronic Manufacturing Service (EMS) refers to a comprehensive process in which specialized companies design, manufacture, test, distribute, and provide repair or return services for electronic components and assemblies. The concept has grown into a global industry worth billions of dollars because nearly every consumer product, industrial machine, or communication device relies on electronics to function.

Why does EMS matter?

Because it streamlines the lifecycle of electronic products. Instead of manufacturers handling design, sourcing, production, and after-sales independently, EMS providers centralize these services. This reduces time-to-market, lowers costs, and ensures higher quality through industry expertise. For businesses, partnering with an EMS provider often means turning complex ideas into commercially viable products faster.

What services fall under EMS?

-

Design & Prototyping: Turning concepts into functional electronic designs.

-

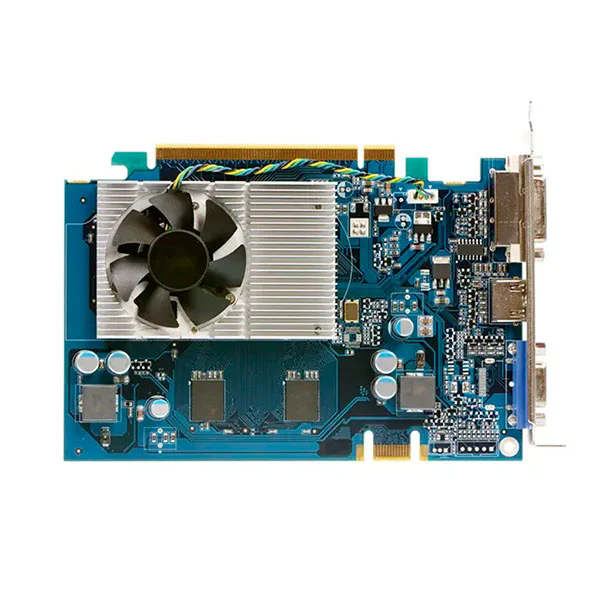

PCB Assembly (PCBA): Manufacturing printed circuit boards with precision.

-

Component Sourcing: Procuring reliable, cost-effective parts from global suppliers.

-

System Assembly: Integrating PCBs, wiring, and housing into full products.

-

Testing & Quality Assurance: Ensuring compliance with international standards.

-

Logistics & Distribution: Managing packaging and global shipping.

-

After-Sales Support: Repair, rework, and warranty services.

The growth of EMS also responds to global demand for innovation. From smartphones to electric vehicles, the pressure to innovate quickly is enormous. Companies without in-house electronic expertise rely heavily on EMS partners to bridge the gap.

How Does EMS Improve Efficiency, Quality, and Scalability?

One of the most critical questions for any business choosing EMS is how it improves operational efficiency. The answer lies in the ability of EMS companies to manage high-volume production while maintaining strict quality.

Efficiency gains:

-

Global Supply Chain Access: EMS providers maintain networks with suppliers, ensuring cost-effective and timely component sourcing.

-

Automation and Robotics: High-tech assembly lines reduce errors and labor costs.

-

Standardized Processes: ISO-certified workflows guarantee consistent product quality.

Quality assurance:

Quality in electronics is non-negotiable. EMS providers implement rigorous standards such as IPC-A-610 for PCB assembly or ISO 13485 for medical electronics. Testing procedures typically include:

-

Automated Optical Inspection (AOI)

-

In-Circuit Testing (ICT)

-

Burn-In Testing for long-term durability

-

Functional Testing against end-use conditions

Scalability and customization:

EMS providers help clients move seamlessly from prototype to mass production. For startups, this means reducing risk during product launch. For established brands, it means adapting quickly to market changes.

Technical Parameters (Sample Capabilities of EMS Providers):

| Parameter | Capability Range/Details |

|---|---|

| PCB Layer Support | 2 to 20 layers |

| Component Package Types | BGA, QFN, QFP, THT, SMT |

| Minimum Component Size | 01005 package (0.4mm × 0.2mm) |

| Production Volume | Prototype runs to millions of units annually |

| Soldering Methods | Lead-free reflow, wave soldering, selective solder |

| Testing Capabilities | AOI, ICT, X-ray, functional, burn-in |

| Certifications | ISO 9001, ISO 14001, ISO 13485, IATF 16949 |

| Turnaround Time | From 24-hour prototyping to 6-8 weeks full scale |

These parameters demonstrate why EMS is attractive: it covers both specialized and mass production demands without compromising flexibility.

Why Do Businesses Across Industries Rely on Electronic Manufacturing Service?

The “why” behind EMS adoption is driven by three major factors: cost savings, expertise, and risk reduction.

Cost savings:

Setting up an in-house electronics manufacturing line requires multimillion-dollar investments. EMS allows companies to bypass this, paying only for the services needed.

Expertise access:

EMS firms employ engineers, supply chain managers, and quality specialists whose combined knowledge is difficult for individual companies to replicate internally. This expertise is particularly critical in sectors such as:

-

Automotive Electronics – sensors, infotainment systems, safety modules.

-

Medical Devices – diagnostic equipment, wearable monitors.

-

Telecommunications – routers, base stations, and 5G equipment.

-

Consumer Electronics – smartphones, wearables, home appliances.

Risk reduction:

EMS providers manage component obsolescence, counterfeit prevention, and compliance with RoHS/REACH regulations. This protects businesses from potential financial and legal exposure.

The versatility of EMS also means it adapts to market dynamics. When supply chain disruptions occur, established EMS providers reroute sourcing strategies quickly. When a client’s product needs redesign to meet updated standards, in-house engineers make the necessary modifications.

EMS is not just a cost-cutting strategy; it is a resilience strategy. In a world where electronics form the nervous system of modern life, EMS providers serve as the silent enablers.

What Does the Future of Electronic Manufacturing Service Look Like and How Can Businesses Choose the Right Partner?

The EMS industry is evolving with digital transformation. Factories are adopting smart manufacturing technologies powered by AI, IoT, and data analytics. This shift, often called Industry 4.0, enhances predictive maintenance, real-time monitoring, and end-to-end visibility.

Future trends shaping EMS:

-

Miniaturization of Components: More compact, higher-density boards.

-

Sustainability Practices: Energy-efficient factories, lead-free soldering, recyclable materials.

-

Vertical Integration: EMS firms expanding into design consulting and supply chain management.

-

Customization on Demand: More flexible production lines supporting small-batch innovation.

How to select the right EMS partner?

When choosing a provider, businesses should evaluate:

-

Technical Capabilities: Can the provider meet your product complexity?

-

Certifications: Are they compliant with industry standards relevant to your sector?

-

Supply Chain Strength: Do they have reliable global sourcing networks?

-

Scalability: Can they support both low-volume prototyping and high-volume manufacturing?

-

Customer Support: Do they offer lifecycle management and after-sales service?

The best EMS partnerships are not transactional but strategic. A strong EMS partner grows with the client, providing solutions for both present and future challenges.

Frequently Asked Questions (FAQ)

Q1: What is Electronic Manufacturing Service in simple terms?

A: It is a specialized service where companies outsource the design, assembly, testing, and delivery of electronic products to expert providers.

Q2: Why should a business use EMS instead of in-house production?

A: EMS reduces costs, speeds up time-to-market, and provides access to advanced technology and global supply chains that are expensive to build internally.

Q3: How do EMS providers ensure product quality?

A: They use international standards, advanced testing methods such as AOI and ICT, and certification frameworks like ISO and IPC to guarantee reliability and compliance.

Partnering with EMS for Long-Term Growth

Electronic Manufacturing Service is more than just a supply chain solution; it is the engine that powers global innovation. From reducing costs to enabling technological breakthroughs, EMS ensures that businesses remain competitive in fast-changing markets. Companies looking to scale efficiently, maintain strict quality, and embrace the future of electronics cannot afford to overlook EMS.

At Fanway, we combine decades of engineering expertise, global sourcing strength, and end-to-end manufacturing capabilities to support businesses in every stage of their product journey. If your company is ready to transform concepts into market-ready electronics with confidence and speed, contact us today to discuss tailored solutions that align with your goals.