What Makes DCDC Constant Voltage Chips the Core of Modern Power Management?

2025-11-13

A DCDC Constant Voltage Chip, often referred to as a DC-DC converter IC, is a key component in modern electronic systems. It transforms one DC voltage level into another with high precision and stability, ensuring that sensitive circuits receive consistent power regardless of fluctuations in input voltage or load conditions. This function is essential in devices ranging from smartphones and computers to industrial control systems, renewable energy modules, and automotive electronics.

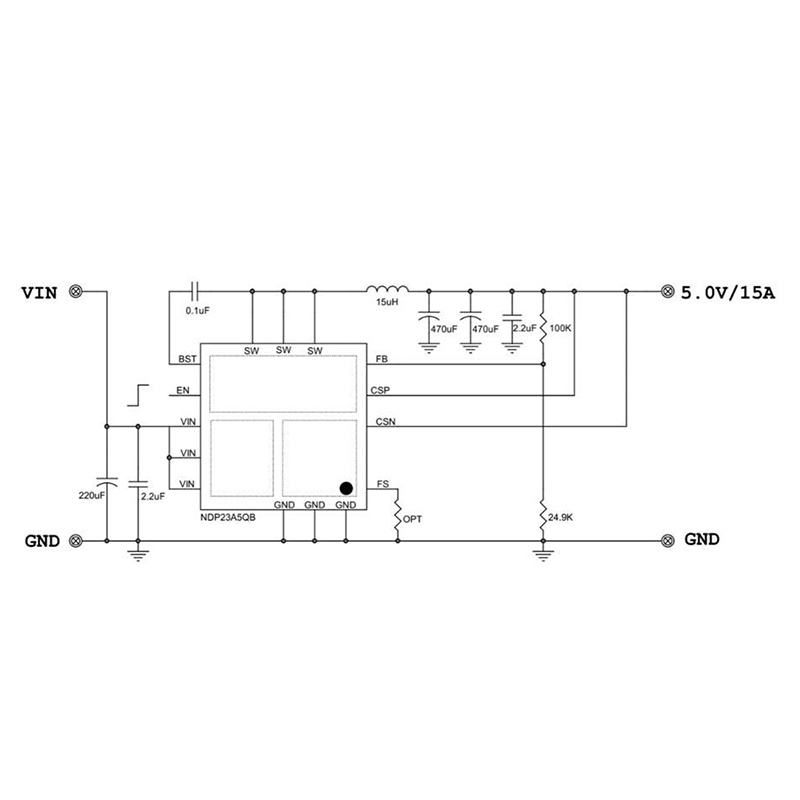

The DCDC Constant Voltage Chip operates by switching and regulating the electrical energy between inductors, capacitors, and transistors, maintaining a fixed output voltage that supports reliable operation. Depending on the design, it may step down (buck), step up (boost), or invert the input voltage.

The heart of these chips lies in their efficiency and stability. Advanced models employ high-frequency switching technology, low standby current design, and integrated protection mechanisms such as overcurrent, overtemperature, and short-circuit protection. These features make them indispensable for applications demanding long-term reliability and precision voltage regulation.

Below is a summary of typical product parameters for a high-performance DCDC Constant Voltage Chip:

| Parameter | Specification |

|---|---|

| Input Voltage Range | 2.7V – 36V |

| Output Voltage | Adjustable 0.8V – 24V |

| Output Current | Up to 5A |

| Efficiency | Up to 96% |

| Switching Frequency | 300 kHz – 2 MHz |

| Operating Temperature | -40°C to +125°C |

| Protection Functions | Overcurrent, Overvoltage, Overtemperature, Short-circuit |

| Packaging Type | SOP-8 / QFN / DFN |

| Control Mode | PWM / PFM Auto-switch |

| Ripple Voltage | <30mV |

This precise parameter configuration ensures stability across a wide range of applications, providing clean, efficient, and reliable voltage regulation.

Why Is the DCDC Constant Voltage Chip So Important in Modern Electronics?

The significance of DCDC Constant Voltage Chips lies in their ability to enhance efficiency, safety, and system performance. As electronic devices become smaller, faster, and more power-hungry, maintaining a stable voltage supply becomes increasingly critical.

A. Energy Efficiency and Heat Management

Conventional linear regulators waste excess energy as heat, while DCDC converters use high-speed switching methods to minimize loss. This leads to higher efficiency—often exceeding 90%—and lower thermal stress on components. This not only extends the product lifespan but also enables compact system designs with reduced cooling requirements.

B. System Stability and Precision

Fluctuating input voltage or inconsistent current can severely affect device performance. The DCDC Constant Voltage Chip regulates these changes, delivering constant power to microcontrollers, sensors, or communication modules. In precision instruments, even a slight voltage drift can distort results; hence, constant voltage output ensures accurate performance.

C. Integration and Miniaturization

Modern DCDC chips integrate multiple functions—control logic, MOSFETs, compensation networks, and protection circuits—into a single compact package. This reduces board space, minimizes external components, and simplifies circuit design, supporting the miniaturization of modern electronics.

D. Enhanced Protection and Reliability

Advanced DCDC Constant Voltage Chips feature built-in safeguards that automatically shut down or limit operation under overload, short-circuit, or thermal stress. This ensures operational safety and prolongs the life of downstream devices, reducing maintenance and replacement costs.

In essence, the DCDC Constant Voltage Chip acts as the “power heart” of electronic systems, balancing performance, protection, and efficiency to ensure consistent operation across varying environments.

How Are DCDC Constant Voltage Chips Shaping Future Technology?

The evolution of DCDC Constant Voltage Chips is tightly linked to global technological trends. The demand for energy-efficient and compact power solutions is driving innovation across industries such as automotive, renewable energy, smart devices, and industrial automation.

A. Integration with Smart Power Management Systems

Future chips will feature intelligent control interfaces capable of dynamic voltage scaling, communication with microcontrollers, and adaptive frequency modulation. These intelligent DCDC chips will optimize energy use in real time, enabling smarter and more sustainable power architectures.

B. Support for Renewable Energy and Electric Mobility

As electric vehicles (EVs) and renewable energy systems gain traction, stable and efficient DC-DC conversion becomes essential. Modern EV systems require multiple voltage rails for battery management, infotainment, and motor control. DCDC Constant Voltage Chips ensure smooth power flow across these complex systems.

In solar power applications, these chips enhance energy conversion from panels to storage systems, ensuring minimal loss and stable output even under varying sunlight conditions.

C. Higher Frequency and Smaller Footprint Designs

The future trend emphasizes miniaturization. By increasing switching frequency and employing advanced materials such as GaN (Gallium Nitride) or SiC (Silicon Carbide), next-generation DCDC Constant Voltage Chips will offer higher efficiency with smaller inductors and capacitors, thus achieving compact yet powerful designs.

D. Enhanced Environmental and Thermal Stability

To meet industrial and automotive-grade standards, new designs are focusing on wide temperature range performance and long-term reliability under harsh conditions. The incorporation of advanced packaging materials and heat dissipation structures will make these chips suitable for demanding applications such as outdoor communication systems and heavy-duty industrial machinery.

E. Digital Control and Monitoring Integration

Digital interfaces like PMBus and I2C are increasingly being adopted in modern DCDC converters. This allows remote monitoring of output voltage, current, and temperature, as well as real-time control adjustments. These smart control features support predictive maintenance and system optimization—crucial for industrial automation and data centers.

The future of DCDC Constant Voltage Chips is defined by efficiency, intelligence, and adaptability, making them foundational components for the next generation of electronic innovation.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between a DCDC Constant Voltage Chip and a Linear Regulator?

A1: A Linear Regulator controls voltage through resistance, dissipating excess power as heat, which results in lower efficiency. In contrast, a DCDC Constant Voltage Chip regulates voltage through high-frequency switching and energy storage components (inductors and capacitors), achieving much higher efficiency—up to 96%—with less heat generation and better adaptability to wide voltage ranges.

Q2: How to choose the right DCDC Constant Voltage Chip for a specific application?

A2: Selection depends on several factors: input and output voltage range, required load current, efficiency requirements, thermal environment, and protection features. For portable devices, high-efficiency and low-ripple chips are recommended. For industrial or automotive applications, wide temperature tolerance and strong protection circuits are essential. Evaluating parameters such as output current capacity, switching frequency, and size compatibility ensures optimal performance for your design.

Why Shenzhen Cokintech Co., Ltd. Leads in DCDC Constant Voltage Solutions

The DCDC Constant Voltage Chip stands at the center of modern power management, transforming raw energy into stable, precise, and efficient voltage for electronic systems across industries. Its continuous evolution—toward higher integration, smarter control, and greater environmental adaptability—positions it as a cornerstone of future technological innovation.

Shenzhen Cokintech Co., Ltd. is committed to developing high-performance DCDC Constant Voltage Chips that deliver superior efficiency, reliability, and stability. With a focus on advanced manufacturing, quality assurance, and technological innovation, the company provides customized power solutions to meet diverse application needs across consumer electronics, automotive systems, and industrial control sectors.

For more information on high-quality DCDC Constant Voltage Chips and tailored power management solutions,

Contact us today to discover how Shenzhen Cokintech Co., Ltd. can power your next generation of technology with precision and performance.