What Is Copper Flexible Connecting Wire?

2025-09-01

Copper Flexible Connecting Wires are essential components in modern electrical systems, designed to deliver superior conductivity, flexibility, and durability. Whether you are powering household appliances, industrial machinery, or advanced electronics, the quality and specifications of the connecting wire play a crucial role in performance and safety.

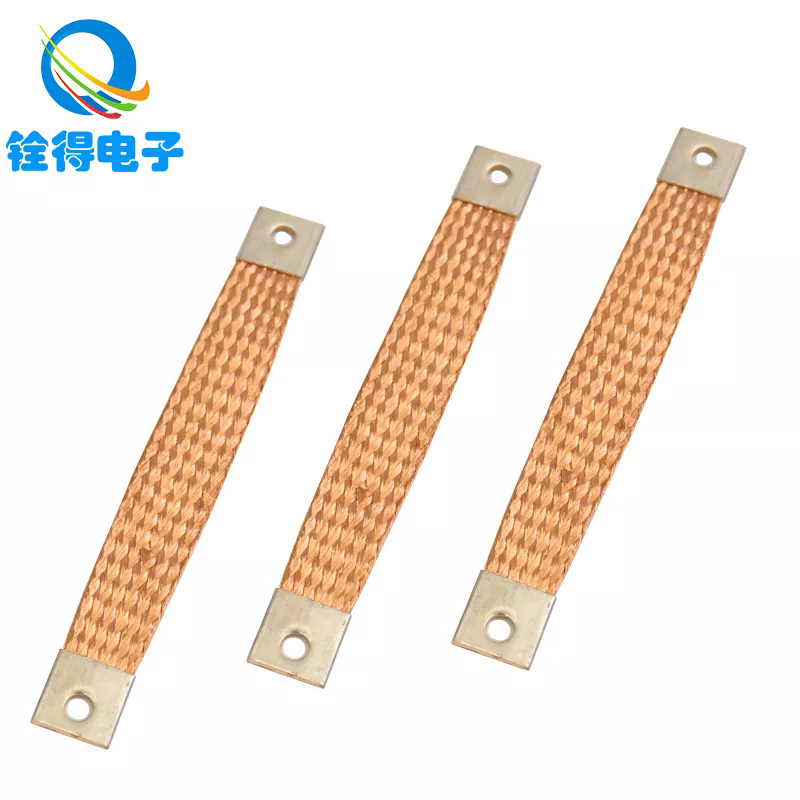

What Is Copper Flexible Connecting Wire?

Copper Flexible Connecting Wire is a high-quality conductor made from multiple thin copper strands twisted together to form a flexible and durable wire. Unlike single-core copper wires, which are rigid, flexible wires allow easy bending and installation, making them suitable for complex wiring layouts. They are widely used in residential, commercial, and industrial electrical systems where adaptability and reliability are critical.

Key Features of Copper Flexible Connecting Wire

-

Excellent Conductivity – Pure copper ensures efficient electrical transmission with minimal energy loss.

-

Superior Flexibility – Multi-strand design provides ease of installation in tight spaces and complex setups.

-

High Thermal Resistance – Withstands high operating temperatures without compromising performance.

-

Corrosion Resistance – Copper material ensures durability and long-term reliability.

-

Safety and Stability – Designed to minimize electrical hazards and maintain stable current flow.

Applications of Copper Flexible Connecting Wire

-

Home Wiring Systems – Powering lighting, sockets, and appliances.

-

Industrial Equipment – Connecting machinery and automation systems.

-

Automotive Wiring – Ensuring stable connections in vehicles and electric cars.

-

Renewable Energy Systems – Used in solar panels and wind turbine connections.

-

Consumer Electronics – Power supply for electronic devices and gadgets.

By choosing the right type of Copper Flexible Connecting Wire, you ensure safer installations, optimized performance, and longer service life.

Technical Specifications and Performance Parameters

When selecting Copper Flexible Connecting Wires, understanding their specifications is vital. Below is a detailed table outlining the essential parameters to consider:

| Specification | Description |

|---|---|

| Conductor Material | 99.9% Pure Copper |

| Construction | Multi-strand fine copper wires |

| Cross-sectional Area | 0.5 mm² to 120 mm² |

| Rated Voltage | 300V / 450V / 600V depending on model |

| Temperature Range | -20°C to +105°C |

| Insulation Material | PVC / XLPE / Silicone |

| Flame Retardant Grade | UL94-V0 compliant |

| Color Options | Red, Black, Blue, Green, Yellow, Brown, White |

| Certifications | CE, RoHS, UL, ISO9001 |

| Flexibility Grade | Class 5 or Class 6 according to IEC 60228 |

Why Specifications Matter

Choosing the right size, insulation, and current-carrying capacity is crucial to avoid overheating, energy loss, and potential fire hazards. For instance, a 10mm² copper flexible wire can handle higher current loads than a 2.5mm² wire, making it suitable for heavy-duty applications like motors and industrial systems.

How to Choose the Right Copper Flexible Connecting Wire

Selecting the right wire depends on several factors, including electrical load, environmental conditions, installation complexity, and safety requirements. Below are key considerations:

A. Determine the Required Cross-sectional Area

The cross-sectional area (CSA) affects the wire’s ability to carry current. For example:

-

1.5 mm²: Ideal for lighting circuits.

-

2.5 mm²: Suitable for household sockets and small appliances.

-

4 mm² – 6 mm²: Best for air conditioners, ovens, and heaters.

-

10 mm² and above: Designed for industrial motors and high-load systems.

B. Consider the Insulation Material

-

PVC Insulation – Cost-effective and widely used for general applications.

-

XLPE Insulation – Offers higher heat resistance and better mechanical strength.

-

Silicone Insulation – Perfect for high-temperature environments and sensitive electronics.

C. Check Environmental Conditions

For outdoor installations or environments with high humidity, wires with enhanced waterproofing and UV resistance are recommended. In automotive or marine applications, abrasion-resistant insulation is preferable.

D. Ensure Compliance with Safety Standards

Always select wires that meet international safety certifications such as UL, CE, and RoHS. Certified wires guarantee reliable insulation, fire safety, and long-term performance.

FAQs About Copper Flexible Connecting Wire

FAQ 1: How do I know which size of Copper Flexible Connecting Wire I need?

Answer:

To determine the correct size, calculate your expected current load (in amperes) and select a wire size that can handle at least 20% more than the maximum current to ensure safety. For example, if your equipment requires 15A, choose a wire rated for at least 18–20A. Refer to the manufacturer’s wire gauge charts to match your requirements accurately.

FAQ 2: Can Copper Flexible Connecting Wires be used for outdoor applications?

Answer:

Yes, but it depends on the insulation type. Standard PVC-insulated wires are suitable for indoor use, while outdoor applications require UV-resistant, waterproof, and weatherproof insulation such as XLPE or silicone-coated options. Always verify the environmental rating before installation to ensure longevity and safety.

Copper Flexible Connecting Wires are an indispensable component in modern electrical and electronic systems, offering unmatched flexibility, conductivity, and reliability. By understanding their specifications and selecting the right size and insulation type, you can optimize performance, enhance safety, and extend the service life of your installations.

For high-quality solutions, Quande provides a complete range of Copper Flexible Connecting Wires that meet international standards and deliver exceptional durability. Whether you're upgrading residential wiring, equipping industrial systems, or powering renewable energy projects, Quande offers reliable products tailored to your needs.

Contact us today to discuss your project requirements and discover the best Copper Flexible Connecting Wire solutions for your applications.