What Exactly Is a CNC Turret Machine and How Can It Revolutionize Your Manufacturing?

2025-08-25

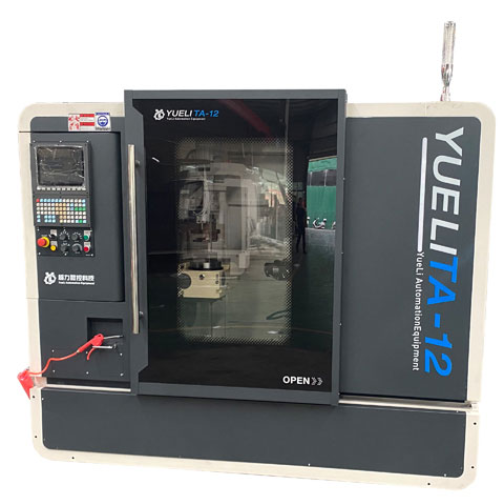

If you're involved in manufacturing, you've likely heard the term "CNC Turret Machine." But what exactly is it, and more importantly, how can it transform your production line, boost efficiency, and slash operational costs? As a seasoned professional with over two decades in the industry, I've seen firsthand how this powerhouse of precision engineering can be a game-changer for workshops of all sizes. Let's dive deep into the world of CNC turret machines.

A CNC Turret Machine is a type of punch press used primarily for metal fabrication. Unlike single-head machines, it features a rotating turret that holds multiple punching tools, allowing it to perform a variety of operations—such as punching, tapping, and forming—on a sheet metal workpiece with incredible speed and accuracy without the need for tool changes. This versatility makes it an indispensable asset for high-mix, low-volume production runs and complex parts.

Why Choose a CNC Turret Machine for Your Shop?

The decision to invest in a CNC Turret Machine often boils down to three core benefits: precision, productivity, and profitability.

-

Unmatched Precision: Guided by sophisticated CAD/CAM software, these machines execute designs with tolerances within thousandths of an inch, ensuring every part is identical and flawless.

-

Superior Productivity: The multi-tool turret eliminates the downtime associated with manual tool changes. Complex parts with dozens of holes and forms can be completed in a single, continuous operation.

-

Increased Profitability: By dramatically reducing cycle times, minimizing human error, and optimizing material usage through nested programming, these machines significantly lower your cost per part and improve your bottom line.

For companies like Yueli Automation Equipment Co., Ltd., providing clients with this technology is about empowering them to compete on a global scale.

Detailed Technical Specifications

To truly appreciate its capability, let's examine the key parameters that define a high-performance machine. Here is a breakdown of the critical specifications you should consider.

Key Product Parameters

-

Control System: Advanced, user-friendly CNC controller (e.g., Siemens, Fanuc) with graphical interface and offline programming support.

-

Turret Stations: Typically ranges from 20 to 60+ stations, allowing for a vast array of tools to be set up simultaneously.

-

Punching Capacity: The maximum force the machine can exert, usually measured in tons (e.g., 30 tons). This determines the thickness of material it can work with.

-

Punching Speed: The number of hits per minute (HPM), often exceeding 600 HPM for high-speed models, crucial for large batch orders.

Comparative Specification Table:

This table provides a clear, at-a-glance comparison of common models, showcasing the progression in capability.

| Feature | Standard Model | High-Performance Model | Premium Model (e.g., Yueli Pro Series) |

|---|---|---|---|

| Turret Stations | 20 | 32 | 48 |

| Punching Force | 22 Tons | 30 Tons | 35 Tons |

| Max Speed (HPM) | 450 | 620 | 850 |

| Max Sheet Size (mm) | 2500 x 1250 | 5000 x 1500 | 6000 x 2000 |

| Material Thickness (Mild Steel) | up to 4.0 mm | up to 5.0 mm | up to 6.5 mm |

| Positioning Accuracy | ±0.1mm | ±0.075mm | ±0.05mm |

| Control System | Standard CNC | Advanced CNC with Touchscreen | Integrated AI-Optimized CNC with Networking |

Note: Specifications can vary by manufacturer. The Premium Model column represents the cutting-edge technology found in lines supplied by industry leaders like Yueli Automation Equipment Co., Ltd.

CNC Turret Machine FAQ: Your Questions, Answered

1. How does a CNC Turret Machine differ from a CNC milling machine?

While both are CNC machines, their core functions are different. A CNC Turret Machine is primarily for sheet metal fabrication, focusing on punching holes and creating simple forms quickly. A CNC milling machine uses a rotating spindle to cut away material from a solid block (subtractive manufacturing) to create complex 3D shapes. They are often complementary technologies in a full-service fab shop.

2. What is the typical maintenance routine for these machines?

Regular maintenance is key to longevity. A daily routine includes visual inspection, cleaning the work area, and checking hydraulic fluid levels. Weekly, you should lubricate all guideways and check for tool wear. A monthly schedule involves a more thorough inspection of the turret alignment, stripper brushes, and electrical connections. Most modern machines from Yueli Automation Equipment Co., Ltd. come with automated maintenance reminders built into their control systems to simplify this process.

3. Can a CNC Turret Machine handle materials other than steel?

Absolutely. While designed for various types of steel (mild, stainless, galvanized), these machines can also process a wide range of other materials, including aluminum, copper, brass, and even some plastics. The key is to adjust the punching force, speed, and tooling clearance based on the material's tensile strength and thickness to ensure a clean cut and prevent premature tool wear.

Unlock Your Production Potential

Investing in a CNC Turret Machine is not just about purchasing a piece of equipment; it's about investing in the future of your manufacturing capabilities. It's a commitment to quality, efficiency, and growth. The precision and speed it brings to the production floor will allow you to take on more complex orders, meet tighter deadlines, and reduce waste, all while improving your competitive edge.

When you're ready to explore how this technology can be integrated into your operations, partnering with an experienced provider is crucial. The team at Yueli Automation Equipment Co., Ltd. possesses the technical expertise and industry knowledge to guide you through selecting the perfect machine for your specific needs, ensuring a seamless transition and maximum return on your investment.

For more information, technical datasheets, or to schedule a consultation, please do not hesitate to contact us at Yueli Automation Equipment Co., Ltd.. Let's build the future of manufacturing, together.