What Are the Cost Factors in Wine Cabinet PCBA Assembly and Components

2025-12-31

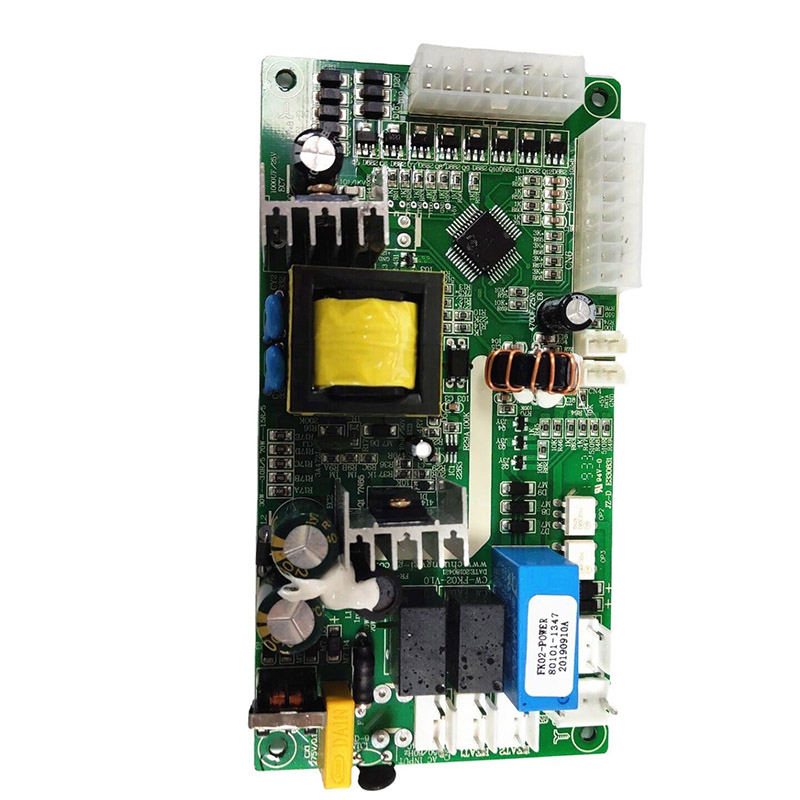

When developing a modern Wine Cabinet PCBA, understanding the cost structure is crucial for balancing performance, reliability, and budget. At SUNSAM, we specialize in delivering high-quality, cost-effective PCB assemblies tailored for the precise demands of wine refrigeration. The total cost is not just about the board itself; it’s influenced by a complex interplay of design choices, component specifications, and manufacturing processes. Whether you are an OEM or a startup, knowing these factors can help you make informed decisions and avoid unexpected expenses.

Several key elements directly impact the final price of your Wine Cabinet PCBA:

-

Design Complexity: The number of layers, board size, and routing intricacy.

-

Component Selection: The choice between standard and specialized, brand-name vs. generic parts.

-

Quality & Certification: Requirements for materials and processes (e.g., UL, RoHS compliance).

-

Order Volume: Economies of scale significantly reduce unit cost.

-

Testing & Inspection: The depth of functional testing, such as temperature cycling for Wine Cabinet PCBA.

To provide a clearer picture, here is a breakdown of typical cost contributors:

| Cost Factor Category | Specific Examples | Impact on Wine Cabinet PCBA |

|---|---|---|

| Core Components | Microcontrollers, Temperature Sensors, Relay Drivers | High-performance, wide-temperature-range components cost more but ensure reliability. |

| Board Fundamentals | FR-4 Material Grade, Copper Weight, Number of Layers | Durable, thermally stable materials are essential for the humid, cool environment. |

| Assembly Process | SMT vs. Through-Hole, Lead-Free Soldering, Conformal Coating | Automated SMT is efficient; protective coating adds cost but boosts longevity. |

| Logistics & Overhead | Component Sourcing, Minimum Order Quantities (MOQs), Shipping | Sourcing from reputable suppliers like SUNSAM stabilizes costs and supply chains. |

Wine Cabinet PCBA FAQ

Q: Why can't I use a standard commercial-grade PCBA in my wine cooler?

A: A standard PCBA is not designed for the specific environment inside a wine cabinet, which involves consistent low temperatures, potential condensation, and long-term 24/7 operation. A dedicated Wine Cabinet PCBA uses components rated for wider temperature ranges and includes protective conformal coating to prevent moisture damage, ensuring decades of reliable service.

Q: How does design complexity affect the lead time and cost?

A: Increased complexity, such as adding more layers for better noise isolation or integrating sophisticated touch controls, requires more design time, advanced manufacturing steps, and rigorous testing. This naturally extends lead time and increases cost. At SUNSAM, we work with clients to optimize designs for both manufacturability and cost without compromising the critical functionality of the Wine Cabinet PCBA.

Q: Is it worth investing in more expensive brand-name components?

A: For critical subsystems like the temperature control module, investing in reputable, A-brand components is highly advisable. They offer better performance consistency, longer lifespans, and higher reliability under stress, which reduces the risk of costly field failures and warranty returns. SUNSAM leverages its supply chain expertise to source optimal components that deliver the best value over the product's entire lifecycle.

Navigating the cost landscape of Wine Cabinet PCBA requires expertise and transparent partnership. By focusing on long-term reliability and total cost of ownership, you can build a superior product that stands out in the market.

Ready to optimize your wine cooling project's cost and performance? Contact the experts at SUNSAM today for a detailed consultation and quote.