Seeking Custom Industrial Control PCBA For Mission-Critical Applications

2025-09-10

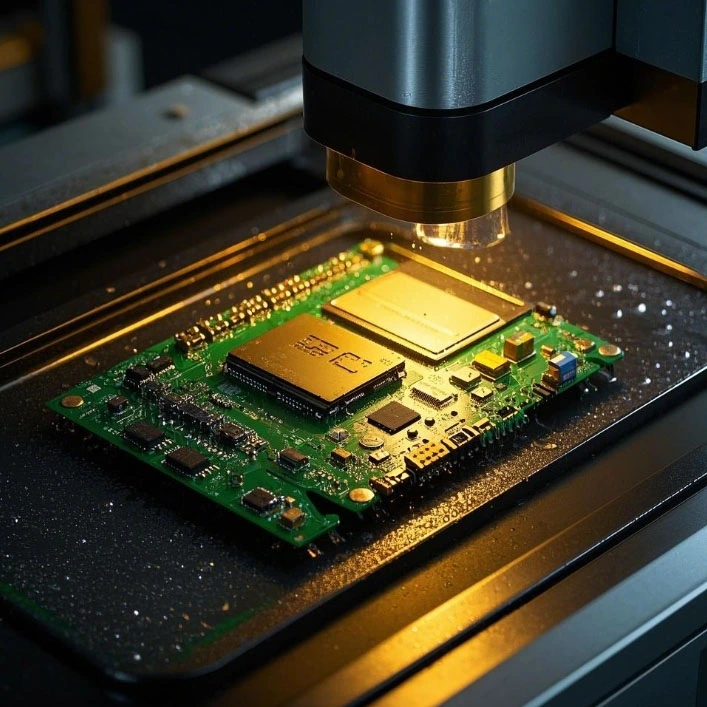

When failure is not an option, your hardware must deliver absolute precision and reliability. For over two decades, Greeting has specialized in manufacturing high-performance Industrial Control PCBA for mission-critical systems across aerospace, medical, energy, and industrial automation sectors.

What Makes Our Industrial Control PCBA Suitable for Critical Applications

We engineer every board to operate flawlessly under extreme conditions—whether it’s high temperatures, mechanical stress, or continuous operation. Our Industrial Control PCBA solutions are built using:

-

Industrial-grade components with extended temperature ranges (-40°C to 125°C)

-

High-reliability substrates (FR-4 High-Tg, Rogers, Polyimide)

-

Conformal coating options for moisture and chemical resistance

-

Compliance with IPC-A-610 Class 3 standards

Technical Specifications at a Glance

| Feature | Specification |

|---|---|

| Max Layers | 20 |

| Min Trace/Space | 3/3 mil |

| Surface Finish | ENIG, HASL, Immersion Silver |

| Testing | 100% AOI, X-ray, ICT, Functional Test |

| Certifications | ISO 9001, ISO 13485, IATF 16949, UL Listed |

FAQ: Industrial Control PCBA

What testing do you perform for high-reliability applications

We execute a full suite of tests including automated optical inspection (AOI), X-ray inspection for hidden solder joints, in-circuit testing (ICT), and functional validation under simulated operational conditions.

Can you support custom design requirements

Yes. We collaborate closely with clients to design and manufacture Industrial Control PCBA tailored to specific environmental, electrical, and mechanical requirements.

What is your typical lead time for prototype and production

Prototype lead times range from 2-3 weeks, while production volumes depend on complexity and quantity, typically 4-6 weeks with flexible acceleration options.

Trusted Partner for Critical Solutions

With deep expertise in designing and delivering robust Industrial Control PCBA, Greeting ensures your mission-critical applications perform as intended—every time.

Contact us today to discuss your project requirements or request a customized quote. Let’s build something reliable together.