Is the Chip Lan Magnetics the Key to Next-Generation High-Speed Ethernet?

2025-10-24

In the evolving landscape of network infrastructure, the compact yet high-performance component known as the Chip Lan Magnetics has emerged as an essential enabler of high-speed connectivity.

What is the Chip LAN Transformer?

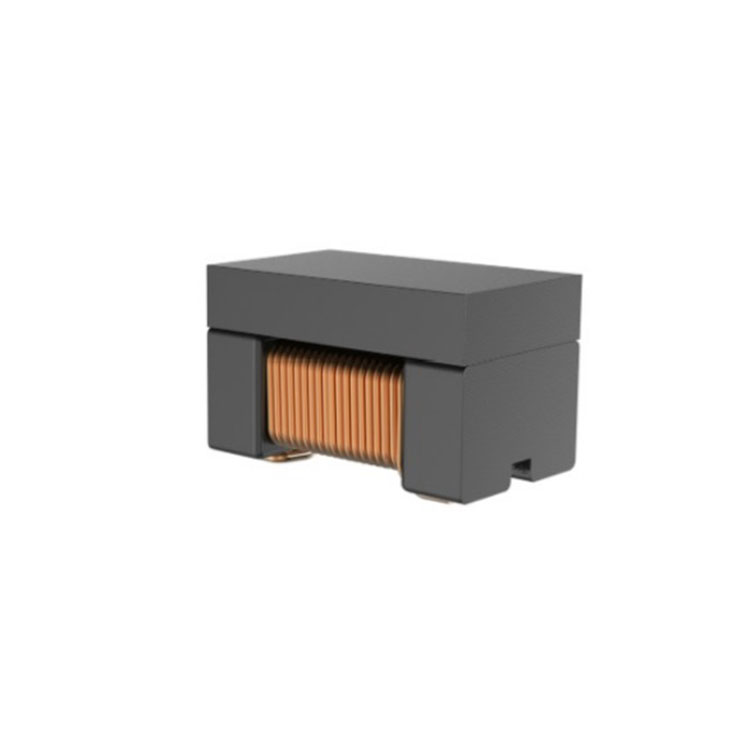

At its core, the chip LAN transformer (sometimes referred to as “Chip LAN Magnetics”) is a small footprint passive component designed for Ethernet data-link interfaces (such as 1G, 2.5G, 5G and 10G BASE-T). It typically integrates a transformer winding (1:1 ratio for isolation) and often a common-mode choke or is paired with one, to support galvanic isolation, impedance matching, signal balancing and electromagnetic interference (EMI) suppression.

Its fundamental role is to sit between the PHY (physical layer transceiver) and the RJ-45/connector module (or magnetics module) in Ethernet equipment, handling line-to-line coupling, protecting the system from differential and common-mode noise, and providing isolation to chassis/ground.

For example, in one manufacturer’s specification table:

| Parameter | Typical Value / Range | Notes |

|---|---|---|

| Data rate support | 1 G / 2.5 G / 5 G / 10 G BASE-T | E.g., part-numbers: LC501 (1 G), LC521 (2.5 G), LC541 (5 G), LC561 (10 G) |

| Package size | ~5.28×3.45×3.40 mm (for single-channel SMD) | |

| Operating temperature | −40 °C to +105 °C (automotive-grade example) | |

| Compliance standards | IEEE 802.3, AEC-Q200 (in automotive variant) |

The central purpose of this article is to clarify both the direct benefits (smaller size, higher speed, improved EMI) and the broader strategic importance (for designers of routers, switches, IoT gateways, automotive Ethernet, PoE systems) of the chip LAN transformer category.

Why is Chip LAN Magnetics Important?

Signal integrity & performance: As network speeds climb (2.5 G, 5 G, 10 G), magnetics design becomes increasingly critical. The chip LAN transformer supports differential signal coupling and common-mode rejection, enabling robust performance over twisted-pair cables. For example, the Microchip application note observes that magnetics are the most commonly used method of meeting isolation and common-mode rejection requirements in 10/100/1000 BASE-T applications.

Miniaturisation and layout flexibility: Traditional magnetics modules were bulky, often encapsulated. Modern chip LAN magnetics are SMD packaged, smaller footprint, suitable for high-density PCB layouts, enabling slimmer devices, reduced board space, and lower cost.

EMI/EMC compliance and isolation: Ethernet ports must meet isolation standards (e.g., 1,500 VAC between ports/chassis) and manage common-mode interference. Magnetics help satisfy these requirements reliably.

Support for Power-over-Ethernet (PoE) and higher data rates: With PoE (and PoE+ / PoE++), magnetics must endure higher currents and thermal stresses; chip LAN magnetics designed for 2.5G/5G/10G and PoE compatibility are increasingly in demand.

Market trend alignment: For networking equipment, data centres, automotive Ethernet and IoT gateways, the shift to higher speeds and smaller form-factors aligns strongly with chip LAN magnetics. Engineering teams selecting components must account for these magnetics early in design to avoid later redesigns.

In summary, from a strategic engineering/SEO perspective, chip LAN magnetics should no longer be treated as “just another passive” — they are enablers of system-level differentiation (faster data, smaller boards, better EMI/thermal). For manufacturers, highlighting features such as “1 G to 10 G support”, “automotive-grade temperature”, “SMD single-channel compact size”, and “PoE ready” will resonate strongly in search queries and design-engineer decision-making.

How Should Chip LAN Magnetics Be Designed, Specified and Integrated?

Specification checklist: When selecting or designing with chip LAN magnetics, consider the following critical factors:

-

Data Rate / Standard Compatibility: Ensure support for desired network speed (e.g., 10/100 BASE-T, 1G, 2.5G, 5G, 10G). Some parts explicitly list this.

-

Package Footprint & Height: For compact designs, look for low-profile SMD packages (e.g., ~3.4 mm height) to fit in slim routers, IoT hubs.

-

Thermal and Current Ratings (PoE support): If PoE or PoE+ is involved, magnetics must handle higher currents and thermal loads; automotive-grade temperature range (−40 °C to +105 °C) is beneficial.

-

Isolation & EMI performance: Check isolation voltage, common-mode rejection, return loss, crosstalk specifications. Magnetics must maintain signal integrity under harsh EMI/EMC environments.

-

Layout flexibility: Discrete chip magnetics offer flexibility in PCB layout versus large potted modules. Designers should still consider co-planarity, thermal paths, signal return paths.

-

Automotive/industrial qualifications: For applications in automotive or harsh environments, look for AEC-Q200 compliance or equivalent.

Integration Tips:

-

Place magnetics close to the PHY to minimise trace length and signal degradation.

-

Maintain correct grounding and shielding practices — magnetics offer isolation but system layout still impacts EMI/EMC.

-

For PoE designs, ensure magnetics and supporting components (chokes, capacitors) are rated appropriately and have thermal relief.

-

For 5G/10G designs, pay attention to insertion loss, return loss, and crosstalk under high-frequency operation; select magnetics that list explicit compliance for higher data rates.

-

Verify package height, footprint constraints especially for blade servers, compact routers, automotive head units.

-

Ensure availability and lifecycle stability — since magnetics are passive but critical, supply chain continuity matters.

-

Simulate or test magnetics under system-level conditions (temperature, vibration, long cable runs) especially for industrial/automotive use.

Common Questions and Answers

Q: What distinguishes a chip-style LAN transformer from a traditional potted module?

A: A chip-style LAN transformer offers a much smaller footprint and profile, SMD compatibility and often discrete integration of transformer + common-mode choke, enabling more flexible PCB layout and reduced height. Traditional potted modules are bulkier, less flexible in layout, and may limit miniaturisation or higher-density board designs. For example, one discrete automotive chip LAN transformer model offered flexible PCB layout compared to potted case modules.

Q: How critical is the magnetics’ performance to overall Ethernet link reliability and EMI compliance?

A: Very critical — magnetics provide galvanic isolation, impedance matching and common-mode noise rejection. Without adequate magnetics, the PHY may be more susceptible to common-mode interference, signal integrity degradation or failure to meet isolation standards (e.g., 1,500 VAC). The Microchip application note emphasises that magnetics are a straightforward solution to many of the interface requirements for 10/100/1000 BASE-T.

Future Trends & Strategic Positioning

As networking demands accelerate, chip LAN magnetics are poised to grow in importance. Key trends include:

Higher Speeds / New Standards: With 2.5G, 5G, 10G BASE-T becoming mainstream, and even 25G/40G emerging in some contexts, magnetics must evolve accordingly. Suppliers already list chip LAN magnetics rated for multi-Gigabit speeds.

PoE++ and Multi-Gigabit PoE: As devices demand power (IoT, cameras, access points, automotive systems), magnetics must support both high data rates and higher power delivery, tighter thermal budgets and smaller form factors.

Automotive Ethernet and Harsh Environments: The push toward autonomous vehicles, ADAS and vehicle-to-everything (V2X) means automotive-grade magnetics (AEC-Q200, −40 °C to +105 °C) will be integral. The example SM453229A-381N7Y automotive chip LAN transformer illustrates this.

Miniaturisation & Integration: As board space shrinks and equipment becomes more compact (edge routers, slim switches, IoT gateways), the demand for ultra-low-profile, integrated magnetics will increase.

EMI/EMC standards tightening: As regulatory and certification requirements become more stringent (especially for automotive, telecom infrastructure), magnetics must deliver superior performance in compact form.

Supply-chain & customisation: Manufacturers will seek magnetics vendors who can deliver automated, high-volume, consistent quality (standardised designs) and support custom footprint/options. Example: one vendor highlights full-automated production, standardised design, short lead times.

Lastly, from a strategic branding viewpoint, companies like Jansum that embed these magnetics in system-level modules (routers, switches, industrial gateways) may highlight their collaboration with high-performance magnetics suppliers and emphasise reliability, miniaturisation and future-proofing of their network interface hardware.

In summary, chip LAN magnetics represent a critical enabler for high-speed Ethernet, miniaturised networking equipment and next-generation connectivity domains such as automotive Ethernet and IoT gateways. Proper specification, integration and forward-looking selection of these magnetics can differentiate a product’s performance, reliability and size in competitive markets. For enquiries or to discuss how to integrate chip LAN magnetics into your system, please contact us at Jansum – we would be pleased to support your design and sourcing efforts.

Contact us.