How to Use Automation and Intelligence in Pcb Assembly?

2025-07-22

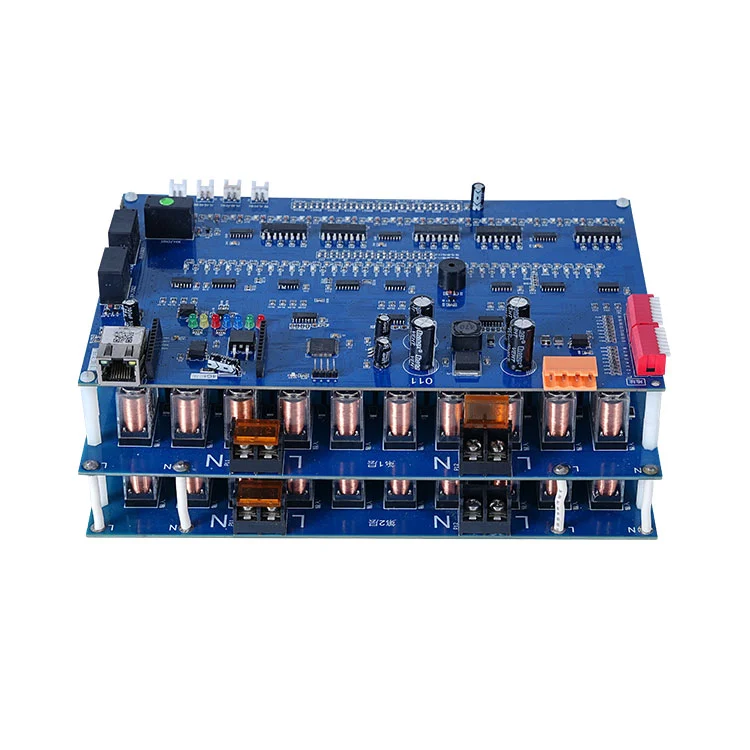

PCB assembly is no longer an era where workers hold soldering irons one by one. The degree of automation is frighteningly high. Let's talk about the placement machine first. Now they all use visual positioning systems, which are much more accurate than the human eye and can identify deviations of 0.01 mm. The system knows where the board on the conveyor belt has gone and how many components have been pasted.

The most powerful part of PCB assembly is the intelligent detection link. The AOI optical detector is equipped with an AI algorithm. It can tell whether there is a cold solder joint or whether the component is pasted crookedly. In the past, it relied on the master's sharp eyes, but now the machine is more reliable than the master. Some factories even use X-rays, and the solder joints of BGA packages hidden under the chip can still be seen clearly.

Intelligent warehousing is also a highlight. The material tower in the SMT workshop will automatically call for materials, and the robot will go to the warehouse to get any components that are missing, without human intervention throughout the process. Even solder paste printing has intelligent monitoring, and an alarm will be issued immediately if the viscosity is not suitable. These intelligent devices have increased the yield rate of PCB assembly and reduced the error rate to below 0.1%.

However, automation must be done within one's means. Small batch and multi-variety orders may not be cost-effective. The key is to find an intelligent solution that suits your factory and not blindly follow the trend. After all, no matter how intelligent the equipment is, someone has to manage it. Technical workers who know how to operate and maintain it are now in high demand.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.