How to Maintain and Extend the Life of a Hollow Cup DC Brush Motor

2025-12-09

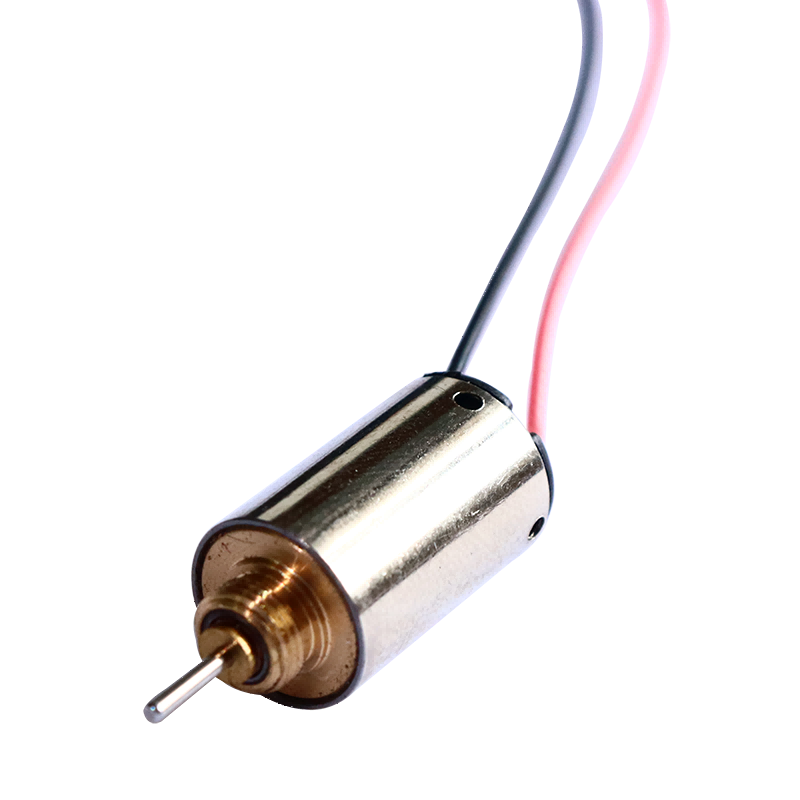

Ensuring the longevity and peak performance of your high-precision motion components is crucial. When it comes to Hollow Cup DC Brush Motors, renowned for their rapid acceleration, low inertia, and smooth operation, proper maintenance is key. At Ruixing, we specialize in engineering superior Hollow Cup DC Brush Motors that deliver exceptional reliability. By following these maintenance guidelines, you can significantly extend the service life of your motor and protect your investment.

Key Maintenance Practices for Optimal Performance:

-

Environmental Control: Always operate the motor within its specified temperature and humidity ranges. Contaminants like dust, moisture, and corrosive agents are major threats. Use protective enclosures when necessary.

-

Electrical Protection: Ensure the power supply is stable and matches the motor's rated voltage. Avoid prolonged overloads and use proper circuitry to prevent voltage spikes or current surges, which can damage the windings.

-

Commutation System Care: For brushed motors, the brush and commutator interface is a wear point. Operate within rated limits to minimize sparking. While Ruixing motors use high-grade materials for extended brush life, listen for unusual noise or check for excessive brush dust as indicators of wear.

-

Mechanical Handling: Prevent axial and radial loads beyond the motor's specifications. Misalignment in the coupling or pulley system induces stress, leading to premature bearing failure. Ensure secure and correct mounting.

Introducing the Ruixing RX-220H Series Hollow Cup Motor

Our Ruixing RX-220H series embodies the perfect balance of performance and durability. Here are its core parameters:

| Parameter | Specification | Benefit |

|---|---|---|

| Rated Voltage | 12 V DC | Standard voltage for easy integration. |

| No-Load Speed | 8500 rpm | High-speed capability for dynamic response. |

| Rated Torque | 8.5 mNm | Consistent power output for demanding applications. |

| Motor Diameter | 22 mm | Compact form factor for space-constrained designs. |

| Weight | 28 grams | Ultra-lightweight, reducing system inertia. |

| Core Feature | Hollow Cup Rotor | Provides exceptionally low electrical time constant and minimal cogging for smooth operation. |

Hollow Cup DC Brush Motor FAQ

Q: How often do the brushes in a Hollow Cup DC Brush Motor need to be replaced?

A: Brush life varies based on operational load, speed, and environmental conditions. Under normal rated conditions, Ruixing Hollow Cup DC Brush Motors are designed for hundreds of hours of operation. Monitoring performance degradation is key, and we provide maintenance guidelines specific to each model.

Q: Can these motors be used in continuous duty applications?

A: Yes, but careful thermal management is essential. Our motors are designed for efficient heat dissipation. Always ensure the application does not exceed the motor's rated current and temperature, and consider active cooling if used in high-ambient-temperature environments.

Q: What makes the maintenance of a Hollow Cup motor different from a traditional iron-core motor?

A: The primary difference lies in the rotor. The absence of an iron core eliminates iron losses and reduces inertia, but the hollow cup winding is delicate. Maintenance focuses more on protecting the windings from mechanical stress and electrical overloads rather than issues like core saturation.

Maximizing the life of your Hollow Cup DC Brush Motor hinges on selecting a quality product and adhering to simple, consistent care practices. By choosing a motor from Ruixing, you invest in a component built with precision and durability at its core. Our technical support team is ready to help you integrate and maintain our motors for optimal, long-term performance.

Contact us today to discuss your application requirements and discover how the reliable, high-performance Ruixing Hollow Cup DC Brush Motor can benefit your project.