How to Functionalize Magnetic Beads for Specific Binding

2025-12-23

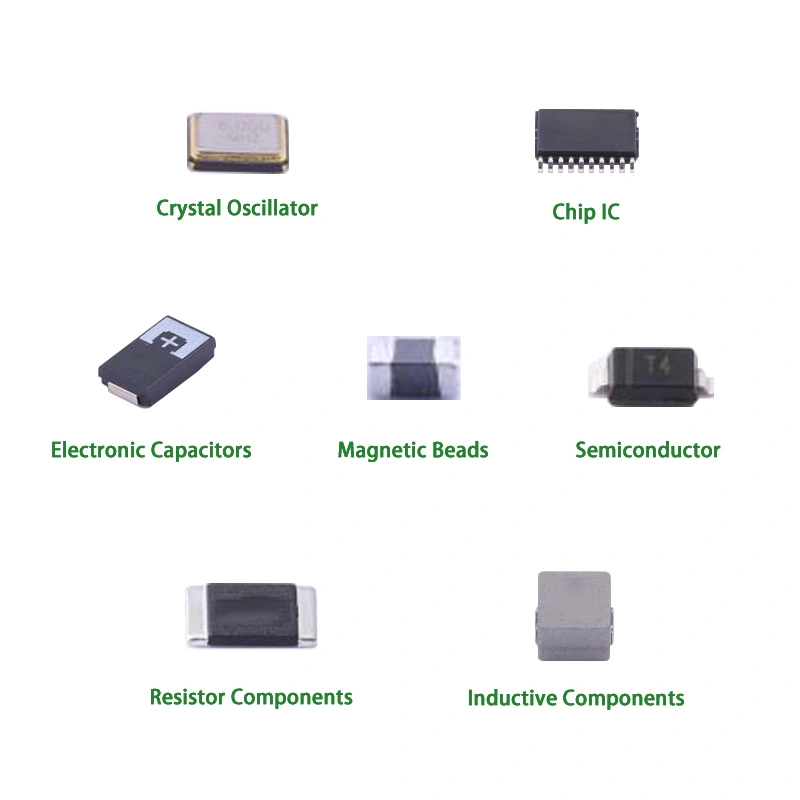

Achieving precise target capture in complex biological samples is a cornerstone of modern diagnostics and research. At the heart of this precision lies a critical process: the functionalization of Magnetic Beads. This technique transforms inert particles into powerful, specific tools for isolation and detection. At Greeting Electronics, we specialize in providing high-quality magnetic bead cores and the expertise to guide their successful surface modification for your unique application needs.

Functionalization involves coating the bead surface with molecules that confer specific binding properties. The right strategy depends entirely on your target molecule.

Common Functionalization Strategies:

-

Streptavidin/Biotin: The gold standard for strong, stable binding.

-

Carboxyl Groups: Activated for covalent coupling to amine-containing biomolecules like proteins.

-

Epoxy Groups: React with various nucleophilic groups for direct antibody binding.

-

Protein A/G: For optimal orientation of antibodies, enhancing antigen capture.

-

Custom Ligands: Peptides, oligonucleotides, or small molecules for unique targets.

Key Steps in the Functionalization Workflow:

| Step | Purpose | Greeting Electronics Tip |

|---|---|---|

| Bead Selection | Choose the right size, material, and surface chemistry. | Our experts can help you select the ideal core bead for your functionalization method. |

| Surface Activation | Prepare the bead surface for ligand attachment. | Consistency in our bead surfaces ensures reproducible activation results. |

| Ligand Coupling | Immobilize the specific binding molecule. | Optimize pH, buffer, and concentration to maximize ligand activity. |

| Blocking & Washing | Reduce non-specific binding to ensure purity. | Use appropriate blocking agents (e.g., BSA, casein) compatible with your downstream assay. |

| Quality Control | Verify binding capacity and specificity. | Test functionalized beads with control targets to validate performance. |

Magnetic Beads FAQ

Q: What factors affect the binding capacity of functionalized magnetic beads?

A: Binding capacity is influenced by bead surface area (size), the density of the functional group, the orientation and activity of the coupled ligand, and the accessibility of the target molecule. Proper optimization of the coupling chemistry is essential.

Q: Can I functionalize magnetic beads myself, or should I buy pre-coated ones?

Q: While possible, in-house functionalization requires expertise and quality control to ensure batch-to-batch reproducibility. For critical applications, high-quality pre-functionalized beads from a trusted supplier like Greeting Electronics often save time and ensure consistent, reliable results.

Q: How do I store functionalized magnetic beads to maintain their activity?

A: Most functionalized beads should be stored in a recommended storage buffer (often containing protein stabilizers and bacteriostatic agents) at 4°C. Avoid repeated freeze-thaw cycles. Always refer to the specific protocol provided with your beads or consult the manufacturer.

Mastering magnetic bead functionalization unlocks specificity and efficiency in your workflows. From selecting the foundational particle to final QC, each step is crucial for success. Greeting Electronics is committed to being your partner in this process, offering not just superior magnetic bead components but also the technical support to ensure your surface chemistry achieves its full potential.

Need help designing the optimal functionalization strategy for your project? Contact our technical support team at Greeting Electronics today to discuss your specific application requirements.