How to Ensure Reliability in High-Flexion Rigid-Flex PCB Applications

2025-12-31

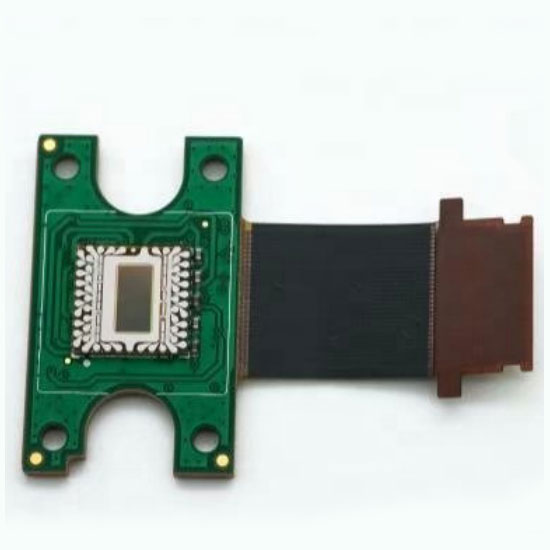

In the demanding world of modern electronics, Rigid-Flex Boards are the engineering marvels enabling the sleek, durable, and high-performance devices we rely on. From medical wearables monitoring vital signs to folding smartphones and mission-critical aerospace systems, these circuits bend and flex without failing. However, achieving rock-solid reliability in high-flexion applications is a significant engineering challenge. At Akeson, we specialize in transforming this challenge into a dependable advantage through meticulous design, material science, and manufacturing precision. This guide outlines the key pillars for ensuring your flexible circuits endure.

Ensuring reliability hinges on three interconnected domains: Design, Materials, and Testing.

1. Strategic Design for Dynamic Flexing

-

Bend Radius Adherence: The fundamental rule. Always design to a bend radius that is a minimum of 6-10x the board's thickness in the flex area to prevent material overstress.

-

Neutral Axis Management: Route critical conductors along the neutral axis of the bend area—where stress is minimal—to protect copper traces from cracking.

-

Transition Zone Reinforcement: The junction between rigid and flexible sections is a stress concentrator. Use tapered stiffeners and avoid placing plated through-holes here.

2. Premium Material Selection

The choice of materials directly dictates performance. The table below contrasts standard and high-reliability options:

| Material Component | Standard Consideration | Akeson High-Flex Recommendation |

|---|---|---|

| Flex Dielectric | Polyimide (Standard) | Adhesiveless Polyimide for enhanced thinness and flexibility |

| Copper Type | Electrodeposited (ED) Copper | Rolled Annealed (RA) Copper for superior fatigue resistance |

| Coverlay/Stiffener | Acrylic Adhesive | Photo-imageable Coverlay (PIC) for precise, reliable openings |

3. Rigorous Application-Specific Testing

Beyond standard tests, high-flexion boards require dynamic validation:

-

Continuous Flex Testing: Simulating millions of bend cycles to validate the design's lifespan.

-

Thermal Shock Cycling: Exposing boards to extreme temperature swings to assess material integrity.

-

HALT (Highly Accelerated Life Test): Applying stresses beyond normal limits to identify failure points early.

Rigid-Flex Boards FAQ

Q: How many times can a Rigid-Flex Board reliably flex?

A: The flex cycle lifespan is not a single number. It is determined by the bend radius, materials used (like RA copper), and the application's motion. A design for frequent dynamic bending, following best practices, can reliably achieve tens of thousands to millions of cycles. Akeson engineers perform detailed mechanical analysis to predict and validate the lifespan for your specific use case.

Q: Can components be placed directly on the flexible section of the board?

A: It is generally not recommended for areas that undergo active bending. Components and solder joints are rigid and can crack under repeated stress. The flexible area should primarily be used for interconnection. Components should be mounted on the rigid sections or on stiffeners specifically added for support.

Q: What is the biggest risk in Rigid-Flex PCB assembly?

A: One of the most critical risks is mishandling or improper support during the assembly process. Flexible sections are delicate and can be easily kinked or torn if not supported correctly in fixtures. A clear assembly guide, proper panelization, and collaboration with your manufacturer are essential. At Akeson, we provide detailed assembly documentation and support to ensure a smooth manufacturing transition.

Achieving unwavering reliability in high-flexion applications demands a partner with deep expertise, not just a supplier. Akeson integrates these principles of robust design, advanced materials, and exhaustive testing into every project, ensuring your Rigid-Flex Boards perform flawlessly in the most demanding environments.

Contact us today to discuss how we can engineer reliability into the core of your next innovative product.