How Printed Circuit Board Innovations Are Shaping Modern Electronics

2025-11-10

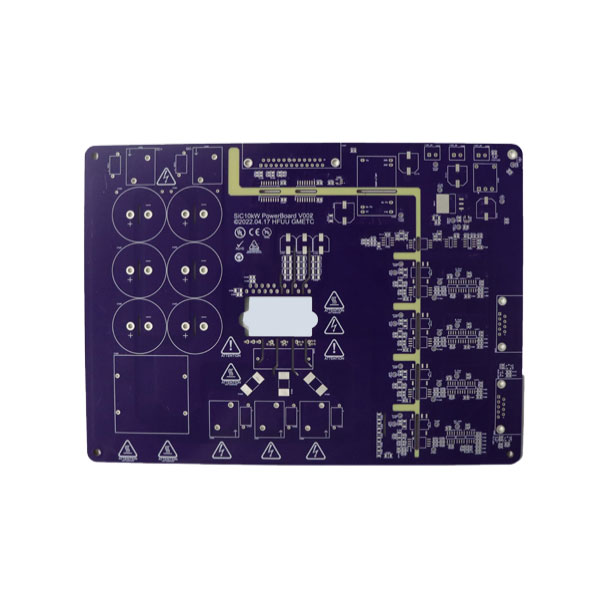

When I joined Fanway over a decade ago, I witnessed firsthand how Printed Circuit Board technology has transformed the electronics industry. Today, these innovations are not just components—they are the backbone of modern devices, from smartphones to industrial machinery. But how exactly are these advancements shaping our world, and what makes a high-quality Printed Circuit Board essential for your projects?

What Are the Key Features Customers Look for in a Printed Circuit Board

As someone who works closely with product development, I often get asked what sets an outstanding Printed Circuit Board apart. In my experience, the following features are critical:

-

Material quality: FR-4, high-frequency laminates, and flexible substrates

-

Layer options: Single-layer, double-layer, multi-layer up to 12+ layers

-

Surface finish: HASL, ENIG, OSP

-

Minimum trace width/spacing: Precision down to 0.1mm

-

Thermal performance: High Tg and low CTE for reliable operation

These characteristics directly influence signal integrity, durability, and the overall performance of electronic devices.

How Do Our Products Meet Modern Electronics Demands

At Fanway, we focus on precision, efficiency, and reliability. Here’s a snapshot of our typical Printed Circuit Board offerings:

| Parameter | Standard Option | Premium Option | Benefit for Customers |

|---|---|---|---|

| Layers | 2-6 | 8-12 | Supports complex circuits |

| Material | FR-4 | High-frequency laminate | High thermal stability |

| Surface Finish | HASL | ENIG | Better solderability and longevity |

| Minimum Trace/Space | 0.2 mm | 0.1 mm | Allows compact, high-density designs |

| Board Thickness | 1.6 mm | 0.8-2.0 mm | Flexible integration into devices |

| Thermal Resistance | Tg 130°C | Tg 170°C+ | Improved heat tolerance for heavy use |

Using these specifications, we ensure that every Printed Circuit Board we deliver meets the exact needs of engineers, designers, and manufacturers.

Why Are Innovations in PCB Design Crucial for Electronics Efficiency

Modern electronics demand smaller, faster, and more energy-efficient solutions. From my perspective, the following innovations make a significant difference:

-

HDI (High-Density Interconnect) Technology for compact devices

-

Flexible and Rigid-Flex PCBs for wearables and IoT products

-

Embedded Components to reduce assembly steps and save space

-

Advanced Thermal Management to ensure high-performance reliability

Each of these improvements solves real customer pain points, such as device overheating, short lifespan, and difficulty in miniaturization.

How Can Customers Choose the Right Printed Circuit Board for Their Projects

Choosing the right PCB starts with understanding your project requirements. Here are practical tips I share with clients regularly:

-

Define your operating environment: temperature, humidity, and mechanical stress

-

Identify power and signal needs: high-frequency, high-current, or sensitive analog signals

-

Determine board size and layer requirements based on device complexity

-

Select surface finish and material to optimize durability and solderability

By carefully evaluating these factors, you can ensure your devices perform reliably in real-world conditions.

What Makes Fanway PCBs the Smart Choice for Engineers and Designers

At Fanway, our mission is simple: provide high-quality Printed Circuit Board solutions that empower innovation. We combine decades of manufacturing expertise with strict quality control, making sure each board is tested and certified before delivery.

If you are ready to enhance your electronics projects with reliable, cutting-edge PCBs, don’t hesitate to contact us today. Our team is happy to answer your questions, provide detailed specifications, and help you select the perfect solution for your unique needs.