How Is the Single Mode Fiber Coupled Laser Module Revolutionizing Precision Manufacturing

2025-11-12

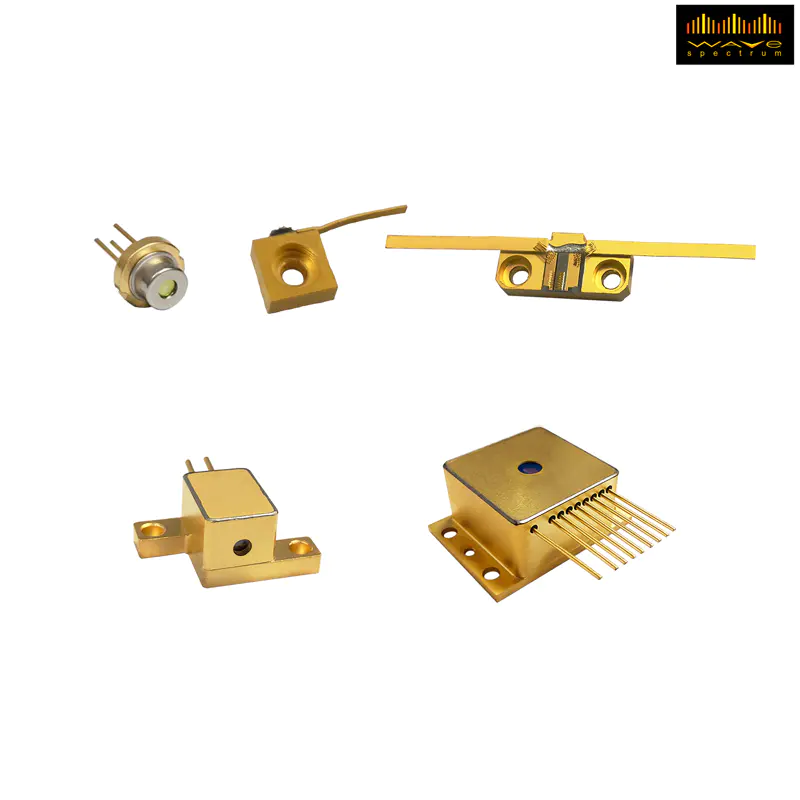

When I first joined Wavespectrum, I never imagined how quickly laser technology would redefine the standards of precision manufacturing. Over the years, we’ve seen a tremendous shift—from bulky, inconsistent light sources to compact, high-efficiency systems that deliver unmatched accuracy. Today, our Single Mode Fiber Coupled Laser Module stands at the center of that transformation, helping manufacturers achieve micro-level precision, higher stability, and consistent performance across production lines.

What Makes the Single Mode Fiber Coupled Laser Module Different in Real-World Applications?

From electronics and semiconductor processing to medical device fabrication, the demand for micron-level control keeps growing. Traditional laser systems often struggle with beam quality and thermal management, leading to production errors or inefficiencies.

Our Single Mode Fiber Coupled Laser Module solves these pain points by providing:

-

Excellent beam quality (M² < 1.2) for ultra-fine cutting and marking.

-

High coupling efficiency, ensuring stable optical output even under continuous operation.

-

Compact structure and lightweight design for flexible system integration.

-

Long-life laser diode core, extending operational hours and reducing maintenance costs.

-

Customizable wavelength and power options for different industrial applications.

How Do Our Technical Specifications Ensure Superior Performance?

Below is a simplified table showing the key parameters of the Wavespectrum Single Mode Fiber Coupled Laser Module that make it ideal for precision manufacturing tasks:

| Parameter | Specification | Advantage |

|---|---|---|

| Wavelength Range | 405nm – 1550nm | Supports multiple application needs (marking, alignment, sensing, etc.) |

| Output Power | 10mW – 500mW | Flexible for both laboratory and industrial use |

| Fiber Type | Single Mode (SMF-28 or equivalent) | Delivers stable, diffraction-limited beam |

| Connector Type | FC/PC or FC/APC | Ensures low back reflection and easy integration |

| Beam Quality (M²) | < 1.2 | Achieves high precision and consistency |

| Power Stability | < ±1% | Guarantees reliable long-term performance |

| Operating Temperature | 10°C – 40°C | Ideal for factory environments |

| Cooling Mode | TEC or Air Cooling | Efficient heat dissipation for extended life span |

Why Is Precision Manufacturing Moving Toward Fiber-Coupled Laser Solutions?

Many of our clients from the semiconductor and biomedical industries shared the same concerns: inconsistent output, poor beam alignment, and short product life cycles. With fiber-coupled solutions, we’ve been able to address these issues head-on.

The Single Mode Fiber Coupled Laser Module provides superior focus and low beam divergence, enabling precise energy delivery to even the smallest targets. The consistent optical alignment also minimizes downtime caused by manual adjustments—something that directly impacts production efficiency.

How Does Wavespectrum Ensure Quality and Reliability?

At Wavespectrum, every module undergoes strict testing—covering optical stability, thermal performance, and environmental adaptability. We use imported laser diodes, premium coupling fibers, and precision alignment technology developed in-house. Before shipment, each product is run through a 24-hour burn-in test to guarantee that it meets our customers’ operational standards.

What Industries Are Benefiting Most from This Technology?

-

Semiconductor manufacturing – wafer inspection, micro-drilling, and photolithography

-

Medical devices – surgical guidance, fluorescence imaging, and laser alignment

-

Electronics – fine marking, micro-cutting, and component soldering

-

Research and development – spectroscopy and optical measurement applications

These applications all require precise, stable, and repeatable light output—something our module delivers consistently.

How Can You Upgrade Your Manufacturing Line with Wavespectrum Solutions?

If you’re looking to improve accuracy, reduce maintenance, or upgrade your production line to next-generation optical systems, our team at Wavespectrum is here to help. We offer full customization, quick technical support, and reliable after-sales service.

👉 Contact us today to learn how the Single Mode Fiber Coupled Laser Module can transform your production capabilities. Our engineers are ready to provide detailed guidance and tailored solutions for your application needs.