How Does LED PCB Improve Modern Lighting Efficiency?

2025-11-14

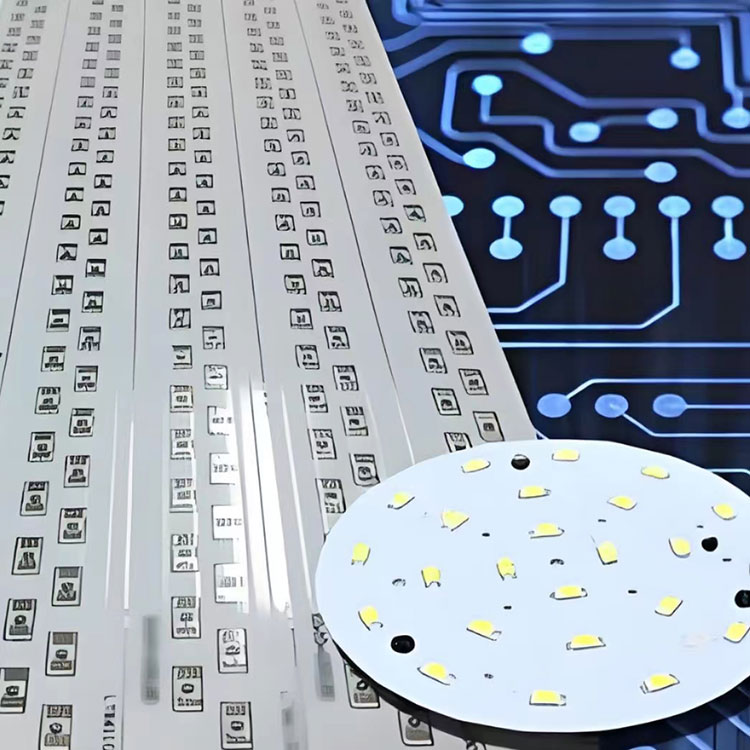

LED PCBs (Printed Circuit Boards) have become the backbone of advanced lighting technology, powering devices from industrial lighting solutions to consumer electronics. Their superior heat dissipation, precision design, and reliability make them essential for modern LED applications.

What Are the Core Advantages of LED PCBs?

LED PCBs offer several benefits over traditional circuit boards, particularly in terms of energy efficiency, thermal management, and durability. Understanding these advantages is critical for industries aiming to implement reliable and long-lasting lighting solutions.

1. Enhanced Thermal Management

LEDs generate significant heat, which can degrade performance and lifespan. LED PCBs are designed with materials like aluminum, copper, or composite metals that efficiently dissipate heat, preventing overheating and ensuring consistent light output.

2. Energy Efficiency

By optimizing the PCB design for low resistance and minimal energy loss, LED PCBs contribute to higher luminous efficiency. This is especially important for large-scale lighting applications where power savings are critical.

3. Long Lifespan and Reliability

High-quality LED PCBs reduce the risk of component failure by providing stable electrical pathways and thermal control. This translates into extended product life, reducing maintenance costs and downtime.

4. Compact and Versatile Designs

LED PCBs allow for highly compact layouts without compromising performance. Flexible and rigid-flex PCBs enable innovative designs for automotive, commercial, and consumer applications.

5. Cost Efficiency Over Time

While initial investment in high-quality LED PCBs may be higher, the long-term benefits include reduced energy consumption, fewer replacements, and lower maintenance costs.

Product Parameters of Typical LED PCB:

| Parameter | Specification |

|---|---|

| Material | Aluminum, Copper, FR-4 |

| Layer Count | 1-6 Layers |

| Thermal Conductivity | 1.0–3.0 W/m·K |

| Surface Finish | HASL, ENIG, OSP |

| Copper Thickness | 1 oz – 4 oz |

| Maximum Operating Temperature | 120°C – 180°C |

| Board Type | Rigid, Flexible, Rigid-Flex |

| Applications | LED Lighting, Automotive, Industrial Electronics |

These parameters highlight how LED PCBs are engineered for high-performance applications, balancing thermal, electrical, and mechanical demands.

Why Are LED PCBs Critical for Modern Applications?

The shift toward LED-based lighting systems is driven by sustainability, efficiency, and design flexibility. LED PCBs are central to these improvements because they directly impact the performance, durability, and cost-effectiveness of the final product.

1. Supporting High-Density LED Arrays

Modern lighting solutions often use high-density LED arrays for uniform brightness. LED PCBs provide the precision and thermal management needed to maintain consistent light output without hotspots or failures.

2. Reducing Energy Costs

By minimizing electrical resistance and improving heat dissipation, LED PCBs allow LEDs to operate at optimal efficiency. This reduces energy consumption and lowers operational costs for businesses and households alike.

3. Enabling Compact and Custom Designs

LED PCBs make it possible to create compact, flexible lighting modules suitable for unique installations, such as curved displays, automotive dashboards, or wearable devices. This versatility is not achievable with conventional circuit boards.

4. Enhancing Safety and Reliability

Overheating and electrical shorts are common concerns in LED assemblies. By ensuring proper heat management and stable electrical pathways, LED PCBs reduce the risk of failures, fire hazards, or decreased product lifespan.

5. Future-Ready for Smart Lighting

As smart lighting and IoT-integrated devices become prevalent, LED PCBs serve as a platform for additional features like sensors, dimming circuits, and wireless communication modules. Their modularity makes upgrades and innovations easier.

How Does LED PCB Technology Evolve for Future Trends?

The LED PCB market continues to evolve, driven by advancements in materials, design techniques, and application demands. Companies seeking to stay competitive must understand the trends shaping the industry.

1. Transition to High Thermal Conductivity Materials

Future LED PCBs will increasingly use materials with superior thermal performance, such as metal core composites and advanced ceramics. This allows for higher power LEDs without overheating, supporting brighter and more efficient lighting solutions.

2. Increased Miniaturization and Flexibility

As devices become smaller and more portable, flexible and rigid-flex PCBs are gaining traction. These designs allow integration into tight spaces and unconventional shapes while maintaining thermal stability.

3. Integration of Smart Features

LED PCBs are evolving to accommodate sensors, communication modules, and dimming controls. This integration supports smart lighting systems that adjust brightness, color temperature, and energy use in real time.

4. Focus on Sustainability

Eco-friendly production processes, recyclable materials, and low-energy designs are increasingly demanded. LED PCBs play a crucial role in enabling energy-efficient products that meet environmental regulations and consumer expectations.

5. Industry-Specific Customization

Different industries—automotive, industrial, consumer electronics—require tailored PCB solutions. Future designs will emphasize modularity and customization, enabling faster deployment across diverse applications.

LED PCB FAQs

Q1: How does the thermal design of LED PCBs affect LED performance?

A1: Proper thermal management ensures that heat generated by LEDs is efficiently dissipated, preventing overheating that can reduce brightness and shorten lifespan. High thermal conductivity materials, such as aluminum cores, combined with optimized PCB layouts, maintain consistent light output and improve overall system reliability.

Q2: What factors should be considered when selecting an LED PCB for high-power applications?

A2: Key factors include thermal conductivity, copper thickness, layer count, material type, surface finish, and mechanical stability. High-power applications demand materials that can withstand elevated temperatures and maintain structural integrity while minimizing energy loss. Choosing the right parameters ensures efficiency, reliability, and longer operational life.

Conclusion: Why Hayner LED PCBs Are a Smart Choice

Hayner LED PCBs offer superior thermal management, high energy efficiency, and robust design flexibility, making them ideal for both standard and high-density LED applications. By investing in high-quality LED PCBs, manufacturers and designers can ensure long-lasting performance, cost efficiency, and future readiness for smart and sustainable lighting solutions. For detailed product inquiries or customized solutions, contact us.