How Does Copper Stranded Wire Improve Electrical Performance?

2025-08-28

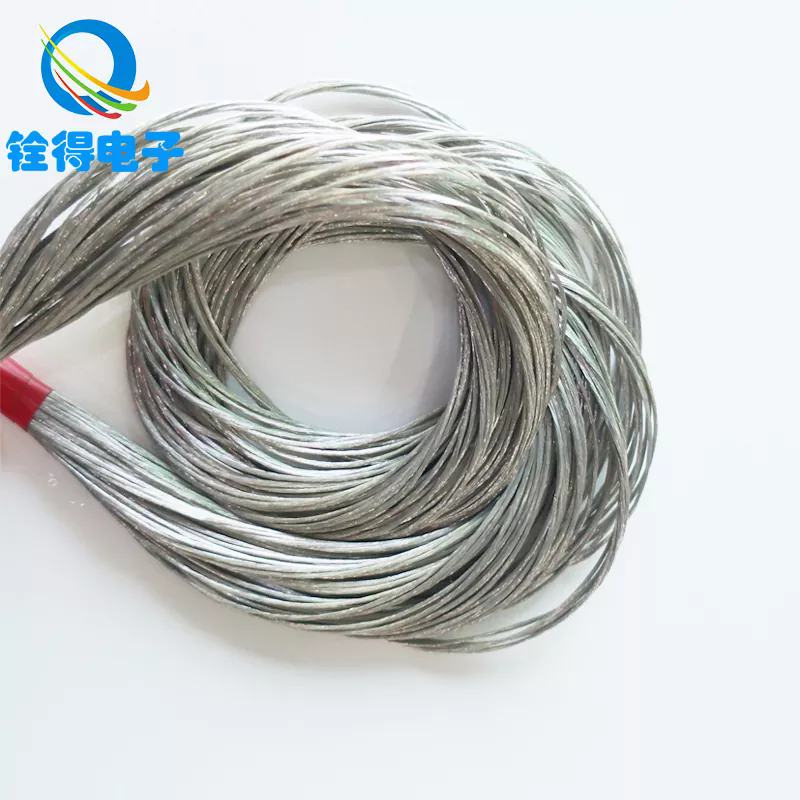

Copper stranded wire plays a crucial role in modern electrical and electronic systems. Unlike solid copper wire, which consists of a single conductor, stranded copper wire is made by twisting together multiple smaller copper wires to form a single, more flexible conductor. This structural difference gives it unique advantages, especially in environments that require high conductivity, durability, and flexibility. Whether used in residential wiring, automotive circuits, industrial equipment, or telecommunications, copper stranded wire delivers outstanding performance.

Understanding Copper Stranded Wire

Copper stranded wire is engineered for situations where both electrical conductivity and flexibility are essential. By bundling multiple fine copper strands, the wire achieves lower resistance, greater bending tolerance, and enhanced vibration endurance compared to solid copper wire.

Key Characteristics of Copper Stranded Wire

-

High Conductivity: Made from pure copper, which provides superior electrical performance.

-

Flexibility: Stranded construction resists fatigue and breakage, making it ideal for applications with frequent movement or vibration.

-

Durability: Designed to withstand bending, twisting, and mechanical stress without losing structural integrity.

-

Corrosion Resistance: Copper naturally forms a protective oxide layer, ensuring longevity even in challenging environments.

How It Differs from Solid Copper Wire

| Feature | Copper Stranded Wire | Solid Copper Wire |

|---|---|---|

| Structure | Multiple twisted copper strands | Single solid copper core |

| Flexibility | High — suitable for movement | Low — prone to breakage |

| Conductivity | Excellent due to larger surface area | Slightly lower than stranded |

| Applications | Automotive, robotics, appliances | Building wiring, fixed circuits |

| Cost | Slightly higher due to manufacturing complexity | Lower cost |

Because of its versatility, copper stranded wire is widely used in industries where performance, reliability, and safety are critical.

Technical Specifications and Parameters

To select the right copper stranded wire, you must understand its key specifications. These parameters directly affect conductivity, insulation, durability, and safety in different applications.

Main Product Specifications

| Parameter | Specification Range | Description |

|---|---|---|

| Conductor Material | 99.9% Pure Copper | Ensures maximum conductivity |

| Stranding Configuration | 7, 19, 37, or more strands | More strands = higher flexibility |

| Conductor Size | AWG 10 to AWG 28 | Defines current-carrying capacity |

| Insulation Options | PVC, XLPE, Teflon, Silicone | Tailored for environmental conditions |

| Voltage Rating | 300V to 1000V | Suitable for low to medium voltage |

| Temperature Range | -60°C to +200°C | Wide operational range |

| Resistance (Ω/km) | As low as 0.015 Ω/km | Lower resistance = higher efficiency |

| Standards Compliance | UL, RoHS, ISO9001 | Ensures quality and safety |

For example, a 16 AWG copper stranded wire typically has 19 strands of 0.259 mm diameter each, achieving a balance between conductivity and flexibility. Choosing the right configuration depends on your intended use — automotive wiring may require high flexibility, while industrial power cables demand thicker conductors for high-current loads.

Key Advantages

-

Superior Flexibility

Copper stranded wire is highly bendable, making it ideal for environments where wiring needs to move frequently, such as robotics and wearable electronics. -

Higher Surface Area for Conductivity

Multiple strands provide a larger overall surface area than a single solid conductor, allowing for better current flow and reduced skin effect losses, especially at high frequencies. -

Vibration and Fatigue Resistance

Unlike solid copper wires that break under repeated stress, stranded wires maintain their integrity, which is essential in automotive and aerospace applications. -

Corrosion Resistance and Longevity

Copper’s natural oxide layer protects against corrosion, ensuring reliable performance even in humid, marine, or industrial environments. -

Compatibility with Various Insulations

Stranded copper wires can be coated with different insulating materials like PVC, silicone, or Teflon to enhance durability and environmental resistance.

Choosing the Right Copper Stranded Wire

Selecting the correct wire involves balancing electrical requirements, environmental conditions, and application-specific constraints.

Copper Stranded Wire – Common FAQ

Q1: What is the main difference between copper stranded wire and solid copper wire?

A1: Copper stranded wire consists of multiple small copper wires twisted together, making it more flexible and resistant to vibration compared to solid copper wire, which has a single conductor. Solid wire is better for fixed installations, while stranded wire excels in dynamic environments where movement is common.

Q2: How do I choose the right insulation for copper stranded wire?

A2: The choice depends on your environment and application:

-

Use PVC for standard home or office wiring.

-

Choose silicone for high-temperature industrial environments.

-

Opt for Teflon when chemical resistance is critical.

-

Go with XLPE for durability in heavy-duty industrial setups.

Copper stranded wire delivers exceptional performance in terms of conductivity, durability, and flexibility, making it an essential component in modern electrical systems. From automotive to aerospace and telecommunications, its adaptability ensures optimal functionality even under demanding conditions.

At quande, we provide premium-grade copper stranded wires engineered for reliability, safety, and efficiency. Whether you need small-gauge wires for electronics or heavy-duty cables for industrial power systems, our products meet the highest international standards.

For customized solutions, bulk orders, or technical consultation, contact us today and let quande support your projects with world-class copper wiring solutions.