How Does a Wire Harness Improve Performance and Reliability?

2025-09-30

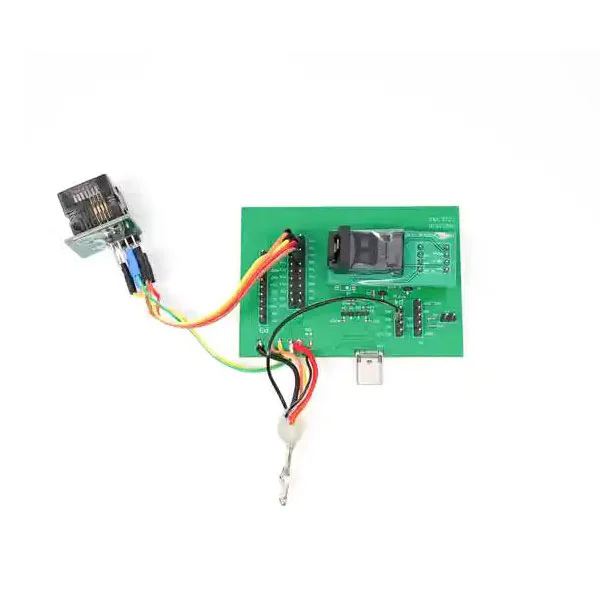

In today’s world, where almost every device relies on power transmission or data communication, the wire harness has become an indispensable component. A wire harness is not just a bundle of wires tied together—it is a carefully engineered system designed to transmit signals or electrical power with maximum efficiency and minimal risk.

By organizing multiple cables into a single, manageable assembly, a wire harness improves reliability, enhances safety, and reduces the possibility of electrical short circuits. From automotive engines to industrial robots and consumer electronics, wire harnesses simplify complex wiring systems, allowing engineers and manufacturers to deliver products that meet strict safety standards and performance requirements.

One of the main reasons industries rely on wire harnesses is their ability to withstand harsh conditions. Temperature fluctuations, vibrations, abrasion, and moisture are common challenges in industrial and automotive environments. A wire harness, with its protective insulation and smart routing, helps prevent wear and tear, prolonging the service life of both the cables and the equipment.

For manufacturers and end-users alike, the value of wire harnesses lies in three main advantages:

-

Efficiency: Easier installation, reduced assembly time, and minimal errors.

-

Safety: Organized wiring reduces overheating and accidental electrical risks.

-

Durability: High-quality insulation materials protect against environmental stress.

As industries demand faster, safer, and more efficient electrical systems, wire harnesses continue to play a central role in innovation and functionality.

How Wire Harness Design Impacts Performance

A wire harness is not a one-size-fits-all solution. Its effectiveness depends heavily on proper design and manufacturing standards. To ensure consistency and reliability, engineers carefully select wire types, connectors, insulation materials, and protective coverings according to the intended application.

Let us explore the critical design aspects that determine how a wire harness performs in real-world conditions:

Key Design Parameters of Wire Harnesses

| Parameter | Description |

|---|---|

| Conductor Material | Copper, tinned copper, or aluminum wires for optimal conductivity. |

| Wire Gauge (AWG) | Selected based on current carrying capacity and application requirements. |

| Insulation Material | PVC, Teflon, or cross-linked polyethylene for resistance to heat and abrasion. |

| Sheathing/Protection | Heat-shrink tubing, braided sleeves, or corrugated tubing for durability. |

| Connectors & Terminals | Crimped or soldered terminals designed for secure fit and conductivity. |

| Temperature Range | Typically from -40°C up to +125°C, depending on application. |

| Voltage Rating | Customized for low-voltage electronics or high-voltage industrial use. |

| Compliance Standards | UL, ISO, or RoHS certifications for safety and environmental compliance. |

Why Proper Design Matters

-

Electrical Efficiency: A well-designed harness ensures signals travel without interruption.

-

Mechanical Reliability: Organized cables reduce mechanical stress on individual wires.

-

Customization: Each industry—automotive, aerospace, industrial automation—requires specific harness designs.

For example, in an automobile engine compartment, wires must endure high heat, chemical exposure, and constant vibration. A customized wire harness with heat-resistant insulation and secure connectors prevents malfunctions that could compromise driver safety. In contrast, a medical device harness prioritizes lightweight design, biocompatible insulation, and precision signal transmission.

When the design is optimized, wire harnesses significantly improve system reliability, minimize downtime, and reduce maintenance costs over the equipment’s lifespan.

How Industries Rely on Wire Harnesses

The applications of wire harnesses extend far beyond basic wiring. They serve as the nervous system of countless machines, ensuring power and signals reach every critical component. Understanding their role in different industries highlights just how essential they are to modern engineering.

Automotive Industry

Wire harnesses are the backbone of modern vehicles. They connect everything from headlights and dashboards to advanced driver assistance systems (ADAS). As electric vehicles (EVs) grow in popularity, wire harnesses must handle higher voltages and integrate smart safety features such as thermal management and shielding against electromagnetic interference.

Aerospace and Defense

In aircraft and defense systems, reliability is non-negotiable. Wire harnesses in this sector must withstand extreme altitudes, rapid temperature changes, and heavy vibrations. Lightweight materials are used to minimize aircraft weight, while shielding ensures secure communication between navigation and control systems.

Industrial Automation

Robotics, conveyor systems, and CNC machinery all rely on precise electrical routing. Wire harnesses in this environment must resist oil, chemicals, and constant motion. Flexible cable assemblies with high abrasion resistance are preferred to maintain consistent performance.

Consumer Electronics

From laptops to household appliances, wire harnesses simplify mass production by organizing multiple wires into single units. This not only reduces production errors but also enhances product safety and user convenience.

Renewable Energy Systems

Solar power plants and wind turbines require robust wiring solutions that can withstand outdoor exposure for years. Wire harnesses with UV-resistant jackets, moisture protection, and high-voltage compatibility ensure uninterrupted energy flow.

The versatility of wire harnesses across industries demonstrates their role as the hidden enabler of innovation. Without them, electrical systems would be disorganized, unsafe, and prone to failure.

How to Choose the Right Wire Harness for Your Needs

Selecting the right wire harness is not simply about finding a standard product; it requires a clear understanding of your application’s demands. The right choice improves performance, reduces costs, and ensures long-term reliability.

Factors to Consider When Selecting a Wire Harness

-

Application Environment – Will the harness be exposed to heat, moisture, chemicals, or vibration?

-

Electrical Requirements – What are the voltage and current needs of the system?

-

Size and Layout – How much space is available for routing the harness?

-

Compliance Standards – Does the harness need to meet UL, ISO, or RoHS certifications?

-

Customization Needs – Are there unique connectors, lengths, or configurations required?

Common Wire Harness FAQs

Q1: How do I know if my equipment needs a custom wire harness instead of a standard cable?

A custom wire harness is necessary when your equipment requires multiple wires to be routed together in a compact, safe, and organized way. Standard cables often cannot handle the complexity of industrial or automotive systems. Custom harnesses allow for tailored connectors, insulation materials, and layouts to fit your specific requirements.

Q2: How does a wire harness reduce maintenance costs?

A wire harness reduces maintenance costs by minimizing wiring errors, protecting wires from environmental stress, and ensuring organized cable management. This decreases the likelihood of electrical shorts, wear-related failures, or accidental disconnections, which translates into fewer repairs and longer equipment lifespans.

Making the Right Investment

For businesses, selecting a high-quality wire harness supplier is just as important as choosing the right design. Reliable suppliers provide not only the product but also engineering support, testing, and compliance certification. Partnering with the right manufacturer ensures your systems remain safe, efficient, and future-proof.

Fanway as Your Trusted Wire Harness Partner

Wire harnesses are the invisible backbone of modern technology, ensuring that power and data flow seamlessly across industries ranging from automotive to aerospace. Their role in improving safety, efficiency, and reliability cannot be overstated.

For companies looking to integrate durable and high-performance wiring solutions, Fanway stands out as a trusted partner. With advanced manufacturing capabilities, strict quality control, and experience in customizing wire harnesses for diverse industries, Fanway helps businesses achieve efficiency, safety, and compliance.

If you are seeking a wire harness solution tailored to your needs, contact us today to explore how Fanway can deliver performance-driven wiring systems that support your long-term success.