How Can Reliable Vehicle Electronics Assembly Improve Automotive Performance and Safety?

2025-10-24

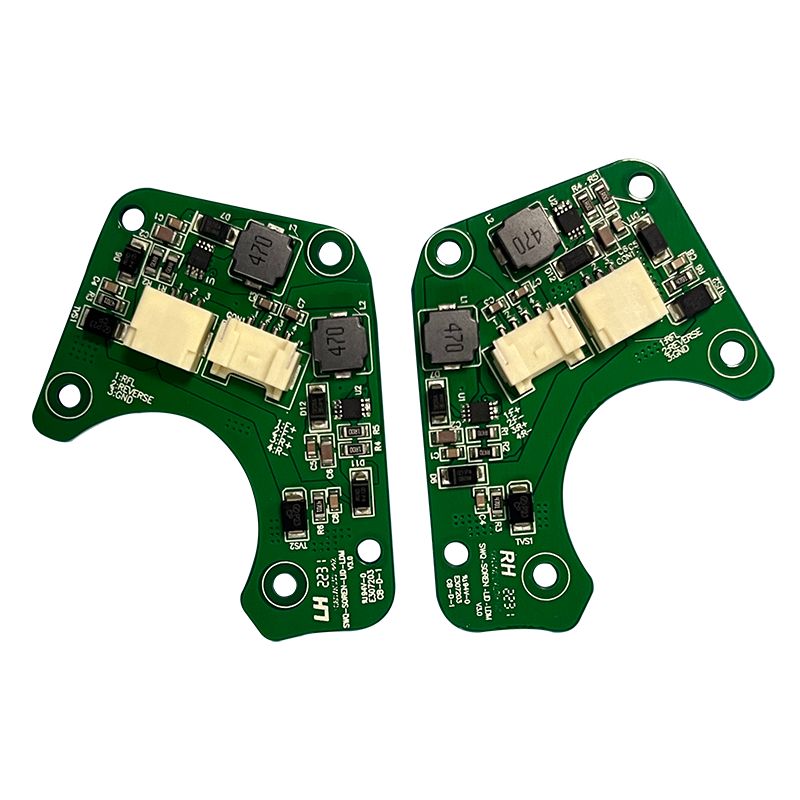

After working in the electronics manufacturing industry for over 20 years, I’ve seen how precision and reliability can make or break an automotive system. At Unixplore, we take pride in designing and assembling high-performance vehicle electronic modules that define consistency and safety on the road. Our Automobile PCBA (Printed Circuit Board Assembly) solutions are built to deliver stable operation under extreme conditions, meeting the evolving demands of modern vehicles.

What Challenges Do Vehicle Electronics Face in Today’s Automotive Industry?

In my experience, the key pain points for automotive electronics lie in temperature fluctuations, vibration, moisture, and long-term durability. A small solder crack or unstable connector can lead to serious performance issues, from dashboard display errors to power-train control failures.

That’s why our assembly process focuses on:

-

High-temperature endurance for under-hood environments

-

Anti-vibration soldering techniques for stable connectivity

-

Moisture-resistant coatings ensuring long lifespan

-

Precise functional testing simulating real-world conditions

These measures help our clients reduce warranty claims, extend product life, and strengthen brand reliability.

What Makes Unixplore Automobile PCBA Different from Standard PCB Assemblies?

At Unixplore, we design each automotive PCBA according to international standards like IATF 16949 and IPC-A-610. But more importantly, our in-house engineering team ensures every circuit board passes through strict functional validation before delivery.

Here’s how our assembly stands out:

| Feature | Description | Benefit |

|---|---|---|

| Multi-Layer PCB (4–10 layers) | Advanced stack-up for high-density design | Compact and space-saving layouts |

| Operating Temperature Range | −40 °C to +125 °C | Reliable for under-hood and high-heat areas |

| Vibration Resistance | Reinforced joints and epoxy protection | Prevents cracking or detachment |

| Surface Treatment | ENIG, OSP, HASL-LF | Corrosion-free solder joints |

| Conformal Coating | Acrylic, silicone, or urethane coating | Moisture and dust protection |

| Testing Process | ICT + FCT + Burn-in 48 hrs | 100 % functionality verification |

| Communication Protocols | CAN, LIN, FlexRay | Compatibility with modern automotive networks |

These parameters ensure our Automobile PCBA solutions perform consistently even under harsh mechanical and thermal stress.

How Do We Ensure Quality and Reliability Throughout the Assembly Process?

When I joined Unixplore’s production team, our goal was simple: zero defects, zero compromises. To achieve that, we’ve invested in fully automated SMT and AOI systems, combined with rigorous traceability and environmental testing.

Our process includes:

-

Component selection – automotive-grade ICs and connectors from verified suppliers.

-

Solder paste inspection – guaranteeing consistent print thickness.

-

Reflow profiling – controlled temperature curve to prevent voids.

-

Automated Optical Inspection (AOI) – detects missing or misaligned parts.

-

X-ray analysis – checks solder joint integrity for BGA components.

-

In-circuit and functional testing – ensures each PCBA meets design intent.

-

Environmental validation – temperature, vibration, and humidity cycles.

Every step is documented digitally for full traceability—essential for OEMs and Tier 1 suppliers seeking long-term reliability.

What Are the Typical Applications of Our Vehicle Electronics Assembly?

Over the years, we’ve supplied Automobile PCBA assemblies to a wide range of automotive systems:

| Application | Function | Example Modules |

|---|---|---|

| Engine Control Units (ECU) | Regulates fuel injection, ignition, and sensors | Powertrain control boards |

| Battery Management Systems (BMS) | Monitors charging/discharging and cell health | EV battery modules |

| Infotainment Systems | Provides connectivity, audio, and display | Multimedia and navigation PCBA |

| Lighting Control Units | Controls LED headlights, taillights, DRL | Smart lighting circuits |

| Safety Modules | Manages airbag deployment and ABS | Sensor and actuator boards |

| ADAS / Sensor Boards | Supports lane-assist and camera processing | Radar and camera PCBA |

Our customers rely on us for both OEM and aftermarket vehicle electronics, trusting Unixplore for consistent assembly precision and fast turnaround.

Why Do Reliable Vehicle Electronics Matter for End Users?

From a driver’s perspective, reliable electronics mean smoother driving, safer response, and lower maintenance costs. From a manufacturer’s point of view, they mean fewer returns, better reputation, and compliance with international safety standards.

I’ve seen clients who switched to our Automobile PCBA solutions experience:

-

30 % fewer field failures within the first year

-

20 % faster assembly integration at their factories

-

Improved heat dissipation and longer circuit lifespan

That’s what we mean by real reliability—engineered, tested, and proven in the field.

How Can Unixplore Support Your Next Automotive Project?

If your project demands high-reliability vehicle electronics assembly with proven performance, Unixplore is ready to help. Whether it’s custom ECU boards, BMS modules, or LED lighting controllers, our team can design, prototype, and mass-produce according to your exact requirements.

Let’s make your vehicle systems smarter, safer, and stronger.

Contact us today to discuss your design files, technical specs, or request a quotation—we’re here to support your success from concept to production.