How Can Large Size HDI PCB Improve Signal Integrity and System Integration?

2025-07-14

Why is signal integrity a key concern in large PCB layouts?

When designing complex, multi-functional boards, maintaining signal integrity across large areas is a real challenge. That’s why I often choose large size HDI PCB—it offers short, direct interconnect paths through stacked microvias and blind vias, reducing delay and crosstalk.

What benefits does large size HDI PCB offer for system integration?

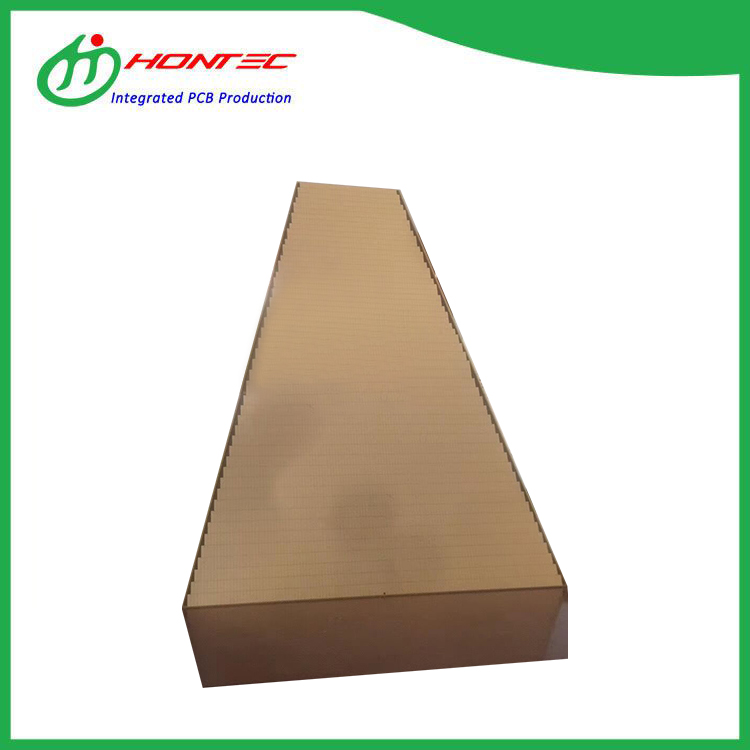

If you're developing high-speed computing modules, satellite electronics, or multi-core processors, the large size HDI PCB provides the space and interconnect density needed for full integration. I’ve collaborated with HONTEC on several large-scale PCBs, and their boards have always met impedance control and thermal stability requirements.

How does HONTEC handle the complexity of large size HDI PCB fabrication?

HONTEC utilizes advanced production techniques such as sequential lamination, laser via formation, and high-Tg materials to ensure their large size HDI PCBs meet the strictest industry tolerances. Their cleanroom facility and multilayer registration accuracy are especially valuable in high-reliability applications.

Is large size HDI PCB suitable for RF and high-frequency applications?

Yes, and that’s one of the reasons I recommend HONTEC. Their large size HDI PCB supports low-loss materials like Rogers and Megtron 6, making it suitable for RF modules and 5G base stations. They also provide impedance simulation support, which has been critical in my telecom projects.

What industries benefit most from large size HDI PCB solutions?

I’ve seen large size HDI PCB used in aerospace, medical imaging, automotive radar, and industrial automation systems. These industries demand high-layer count, tight tolerances, and fast turnaround—all of which HONTEC delivers with consistency.

Looking to streamline your high-end PCB development?

If your project demands high-density, large-format boards, I strongly recommend working with HONTEC. Their large size HDI PCB solutions are engineered for precision, performance, and reliability.

Our products are highly reliable. If you have any cooperation or bulk purchase needs, please contact us. We offer 24-hour online quality service.