How Can AI Revolutionize Your PCB Production Quality

2025-08-27

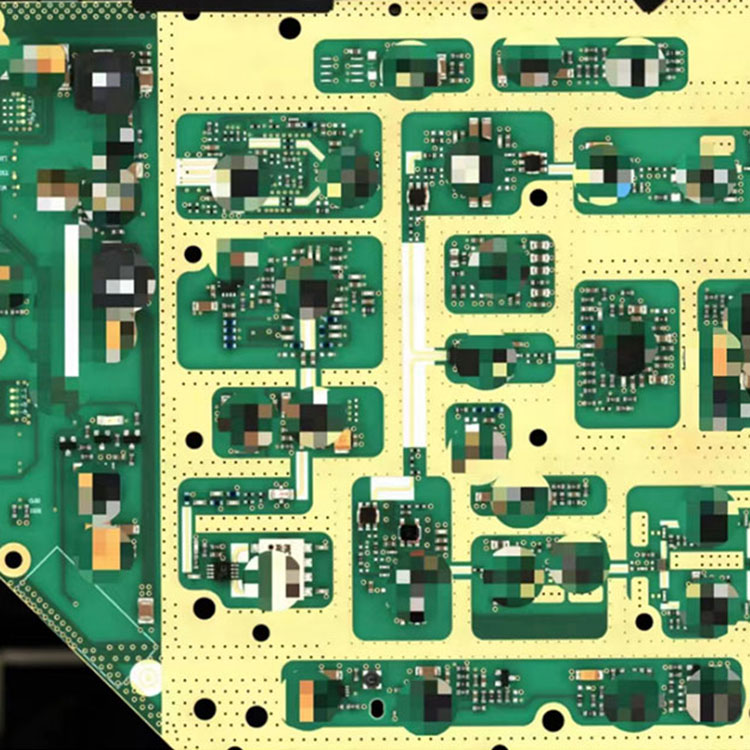

For decades, PCB Fabrication has relied on the precision of engineers and the consistency of machines. But what if you could predict a failure before it happens? What if every board could be inspected with superhuman accuracy? This is no longer a future concept—it's today's reality powered by Artificial Intelligence. At Hayner, we are leveraging AI to set a new benchmark in quality and reliability, transforming how printed circuit boards are manufactured.

How Does AI Enhance Precision in Manufacturing

AI algorithms thrive on data. By analyzing thousands of design files and PCB Fabrication outcomes, our systems learn to identify patterns invisible to the naked eye. This allows for predictive corrections in the manufacturing process.

-

Predictive Defect Prevention: Our AI cross-references your design with our historical production data to flag potential areas for etching issues, solder bridges, or micro-shorts before a single board is made.

-

Automated Optical Inspection (AOI) 2.0: Traditional AOI can have high false-positive rates. Our AI-driven imaging systems learn from every board they inspect, dramatically increasing fault detection accuracy while reducing time-consuming false alarms.

-

Optimized Panelization: AI software automatically calculates the most efficient panel layout for every project, minimizing material waste and maximizing throughput for cost-effective production.

What Are Hayner's AI-Driven Product Specifications

Our AI capabilities are built upon a foundation of advanced manufacturing specifications, ensuring we handle even the most complex orders with impeccable quality.

| Feature | Standard Capability | Hayner AI-Optimized Enhancement |

|---|---|---|

| Minimum Trace/Space | 3/3 mil | AI-powered monitoring ensures consistent precision, even at tolerance limits. |

| Layer Registration | ±2.5 mil | AI vision systems dynamically adjust drills and layers for near-perfect alignment. |

| Surface Finish | ENIG, HASL, etc. | AI predicts the optimal finish application for your specific assembly environment. |

PCB Fabrication FAQ

What is the biggest advantage of using AI in PCB fabrication

The most significant advantage is the shift from reactive detection to proactive prevention. AI doesn't just find faults; it predicts and helps us eliminate them at the source, leading to a higher yield and more reliable boards from the very first panel.

How does AI improve accuracy in multilayer PCB alignment

Our AI-driven systems analyze real-time data from drilling and imaging machines to make micro-adjustments for thermal expansion and material drift. This results in superior layer-to-layer registration, which is critical for the functionality of high-density interconnect (HDI) designs.

Can AI in the manufacturing process reduce costs

Absolutely. By drastically reducing errors, rework, and material waste, AI streamlines the entire production process. This allows us to offer highly competitive pricing without ever compromising on the quality that Hayner is known for.

See the Hayner Difference in Your Next Project

Integrating AI is not just an upgrade; it's a fundamental shift towards intelligent manufacturing that guarantees unparalleled quality. This commitment to technological innovation ensures that your designs are transformed into flawless, high-performance boards.

Contact us today to get a quote and experience how our AI-optimized PCB Fabrication process can elevate your product's quality, reliability, and time-to-market.